−

14

−

②

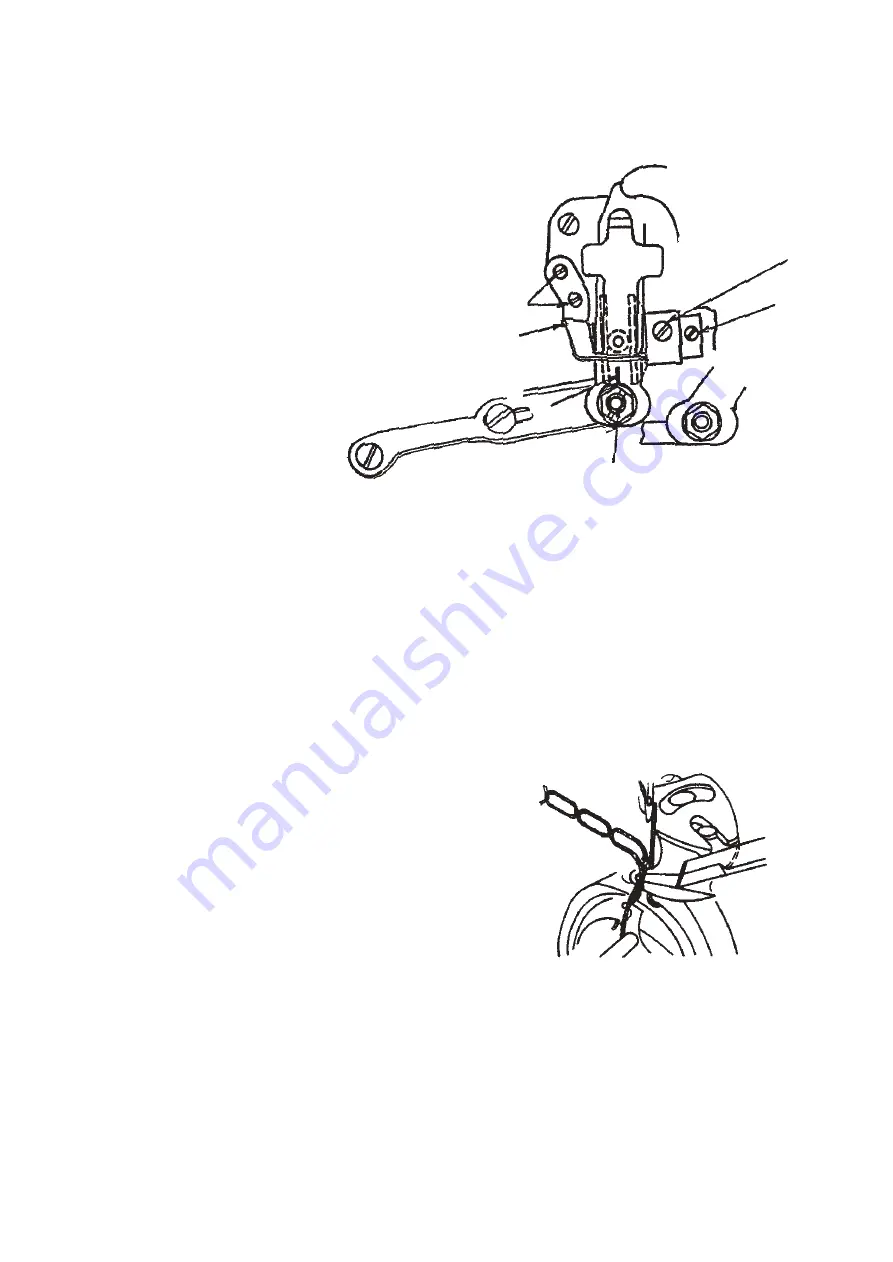

Adjust so that the center of moving knife link pin

is aligned with V groove (Fig. 15 (2)) of the center

of slot in knife driving arm (Fig. 15 (3)), and tighten

the lock nut to fix the pin.

③

Loosen two setscrews (Fig. 15 (4)) in driving arm

stopper (Fig. 15 (5)).

④

Move knife driving arm (Fig. 15 (2)) so that V

groove (Fig. 14) on the knife installing base is

aligned with the periphery of moving knife, press

it to driving arm stopper (Fig. 15 (4)) at that

position, and tighten setscrews (Fig. 15 (5)).

⑤

Loosen the respective two setscrews in thread trimmer cam (Fig. 15 (7)) and cam collar (Fig. 15 (6)).

⑥

Align marker dot (red : Fig. 13 (2) or green (3)) on the handwheel with marker dot (Fig. 13 (1)) on the

machine arm.

⑦

Turn with finger top setscrew No. 2 (Fig. 15 (7)) in the thread trimmer cam so that it comes to this side, and

press the thread take-up picker to the right when the setscrew comes to this side.

⑧

Move the cam to the right and left to engage the cam with the roller.

⑨

In this state, lightly pulling the cam to the right, move it in the direction of arrow (this side) until it will rotate

no further.

⑩

Temporarily tighten setscrew No. 2 (Fig. 15 (7))

in the cam.

⑪

At this time, check the following matters :

a) Marker dot on the handwheel is aligned with

that on the machine arm.

b) Roller smoothly enters the groove in the cam.

c) Amount of recession of knife is 2.5 to 3 mm

(SH : 3 to 3.5 mm).

⑫

Securely tighten two setscrews in the cam.

⑬

Press cam collar to the cam, and tighten one

setscrew.

[Caution]

○

Amount of recession of knife is largely affected even when adjustment of left and right

positions of moving knife link pin is finely performed.

○

Check whether moving knife handles thread as shown in Fig. 16.

(1)

(5)

(4)

(3)

(6)

(7)

(2)

Fig. 15

Fig. 16