– 1 –

1. SPEcIFIcatIoNS

!

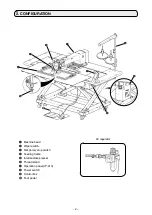

. MEcHaNIcaL SEctIoN (WItH rEGarD to tHE SEWING MacHINE)

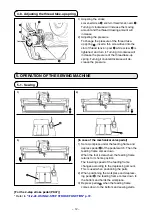

1 Sewng area

X (lateral) drecton

Y (longtudnal) drecton

AMS-224E-4530

: 450 mm ×

300 mm

AMS-224E-6030 : 600 mm × 300 mm

2 Max. sewng speed

2,500 st/mn (When sewng ptch s 3 mm or less)

3 Settable sttch length

0.1 to 12.7 mm (Mn. resoluton : 0.05 mm)

4 Feed moton of feedng frame Intermttent feed (2-shaft drve by steppng motor)

5 Needle bar stroke

41.2 mm

6 Needle

DP x 17

7 Lft of feedng frame

Max. 30mm

8 Intermedate presser stroke

4 mm (Standard) (0 to 10 mm)

9 Lft of ntermedate

presser

20 mm

10 Intermedate presser

DOWN poston

varable

Standard 0 to 3.5 mm (Max. 0 to 7.0 mm)

11 Shuttle

Double-capacty sem-rotary hook

12 Lubrcatng ol

New Defrx Ol No. 2 (Suppled by oler)

13 Memory of pattern

data

• Man body : Max. 200 patterns (Max. 20,000 sttches/pattern)

• External meda : Max. 999 patterns (Max. 50,000 sttches/pattern)

14 Temporary stop faclty

Used to stop machne operaton durng a sttchng cycle.

15 Enlargng / Reducng

faclty

Allows a pattern to be enlarged or reduced on the X axs and Y axs ndependently

when sewng a pattern. Scale : 1% to 400% tmes (0.1% steps)

16 Enlargng / Reducng

method

Pattern enlargement / reducton can be done by ncreasng / decreasng ether sttch

length or the number of sttches. (Increasng/decreasng sttch length only can be

performed when pattern button s selected.)

17 Max. sewng speed

lmtaton

200 to 2,500 st/mn (Scale : 100 st/mn steps)

18 Pattern selecton

faclty

Pattern No. selecton method

19 Bobbn thread counter

UP/DOWN method (0 to 9,999)

20 Sewng counter

UP/DOWN method (0 to 9,999)

21 Memory back-up

In case of a power nterrupton, the pattern beng used wll automatcally be stored n

memory.

22 2nd orgn settng

faclty

Usng jog keys, a 2nd orgn (needle poston after a sewng cycle) can be set n the

desred poston wthn the sewng area. The set 2nd orgn s also stored n memory.

23 Sewng machne motor Servo-motor

24 Dmensons

AMS-224E-4530 : 1,703mm (W) x 1,370mm (L) x 1,200mm (H) (Excludng thread stand)

AMS-224E-6030 : 1,923mm (W) x 1,370mm (L) x 1,200mm (H) (Excludng thread stand)

25 Mass (gross mass)

AMS-224E-4530

: 401 kg

AMS-224E-6030

: 410 kg

26 Power consumpton

550 VA

27 Operatng temperature

range

5˚C to 35˚C

28 Operatng humdty range 35 % to 85 % (No dew condensaton)

29 Lne voltage

Rated voltage ±10% 50 / 60 Hz

30 Ar pressure used

AMS-224E-4530

: 0.5 to 0.55 MPa (Max. 0.55 MPa)

AMS-224E-6030

: 0.5 to 0.55 MPa (Max. 0.55 MPa)

31 Ar consumpton

1.8 dm

3

/ mn (ANR)

32 Needle hghest

poston stop faclty

After the completon of sewng, the needle can be brought up to ts hghest poston.

33 Nose

'- Equvalent contnuous emsson sound pressure level (L

pA

) at the workstaton :

A-weghted value of 83.5 dB ; (Includes K

pA

= 2.5 dB) ; accordng to ISO 10821- C.6.3

-ISO 11204 GR2 at 2500 st/mn.

'- Sound power level (L

WA

) :

A-weghted value of 92.5 dB ; (Includes K

pA

= 2.5 dB) ; accordng to ISO 10821- C.6.3

-ISO 11204 GR2 at 2500 st/mn.