26

ENGLISH

approved for solid fuel fireplaces with flue gas temperatures

as specified in

«2.0 Technical data»

in the insert manual.

•

The cross-section of the chimney must be at least that of the

flue pipe. To calculate the correct chimney cross section, see

«2.0 Technical data»

in the insert manual.

• Several solid fuel products can be connected to the same

chimney system if the chimney cross-section is adequate.

Contact your local building authorities regarding restrictions

and installation requirements.

•

Connection to the chimney must be performed in accordance

with the installation instructions of the chimney supplier.

•

Make sure that the flue pipe rises all the way up to the chimney.

•

Please note that it is extremely important for connections to

have a degree of flexibility.

For recommended chimney draught, see «2.0 Technical data» in

the insert manual

.

4.9 Preparation

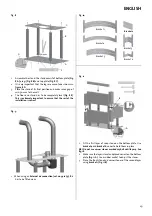

The basic product is supplied in two packages:

1. the burn chamber,

2. and soap stones with mounting sections.

NB: Check that there is no visible damage to the product when

you unpack it, and make sure that the control handles move

freely.

The burn chamber is heavy, – make sure it does not topple over

while you are installing it!

Ensure you have help when positioning and installing it.

The product is supplied together with 3 manuals:

1. General user and maintenance manual

2. Jøtul

FS

165

- I

400

FL (surround)

3. Jøtul

I

400

FL

(burn chamber)

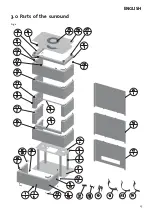

The surround consists of the following elements

(Fig. 2):

Part

Description

Total

2

Bottom plate

1 pcs

3 Leg

4

pcs

4

Insert support plate

1 pcs

5

Side stone

12 pcs

6

Corner stone

10 pcs

7

Front stone

4 pcs

8

Front stone, low

1 pcs

9

Corner stone over insert

2 pcs

10

Top stone, front

1 pcs

11

Top stone, left

1 pcs

12

Top stone, right

1 pcs

13

Top grid

1 pcs

14

Support bracket

1 pcs

15

Rear plate, upper

1 pcs

16

Rear plate, middle

1 pcs

17

Rear plate, lower

1 pcs

18

Bracket 1

6 pcs

19

Bracket 3

10 pcs

20

Bracket 6

4 pcs

21

Bracket 5

4 pcs

22

Bracket 2

6 pcs

23

Bracket 4

4 pcs

24

Screw countersink unb, M6x16

8 pcs

25

Smoke outlet cover

2 pcs

26

Heat shield, top

1 pcs

27

Distance piece

4 pcs

4.0 Prior to installation

4.1 Foundations

You need to make sure the foundation is suitable for a stove. See

“2.0 Technical data” for specified weight.

Remember: If a steel chimney resting on the burn chamber is

being used, the weight of the steel chimney should be taken

into account.

NB: It is extremely important that the product be stable; the

surface it is installed on must be completely inflexible.

It is recommended that flooring that is not attached to the

foundation – «floating floors» – be removed beneath the product.

4.2 Floor covering

Jøtul FS

165

- I

400

FL has an airtight bottom plate and no

extra floor covering is required beneath the product.

Any floor covering of inflammable material, such as linoleum,

carpets, etc. must be removed from under the product.

4.3 Floor plate

A plate made of steel or some other suitable non-inflammable

metal (optional extra) is placed in front of the hearth.

The floor plate must comply with national laws and regulations.

Contact your local building authorities regarding restrictions and

installation requirements.

4.4 Air supply

There must be a flow of air between the burn chamber and the

surround. This is to ensure that there is not too great a build-up

of heat inside the surround.

NB: It is extremely important that air openings not be covered.

See

fig. 1

for distances.

4.5 External air

A flexible supply hose allowing external air to be fed directly into

the product can be passed through the opening in the rear plate.

See separate manual.

4.6 Steel chimney

If a top-mounted steel chimney is used, an uninsulated pipe is

fitted from the burn chamber to approximately

10 mm

through

the top stones. Make sure that the gasket is properly seated

between the flue pipe and the smoke outlet. Then fit the steel

chimney in accordance with the chimney supplier’s installation

instructions.

4.7 Ceiling

Make sure the room where the Jøtul FS

165

- I

400

FL is to be

placed has a ceiling height of

at least 2300 mm

.

4.8 Chimney and flue pipe

• The stove must be connected to a chimney and flue pipe

Summary of Contents for FS 165-I 400 FL

Page 6: ...25 3 0 Parts of the surround Fig 2 ENGLISH...

Page 14: ...83...