BP-1000K

User’s Manual

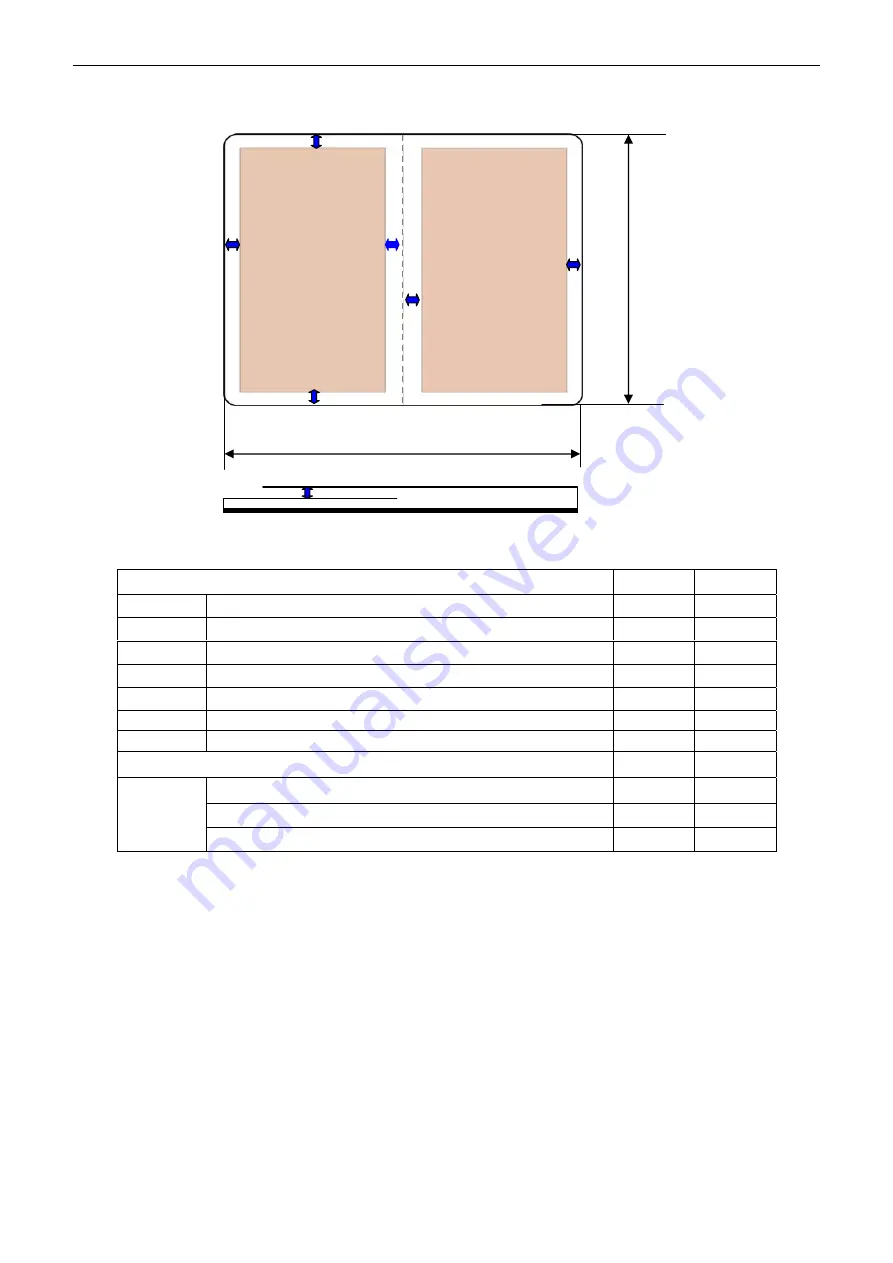

6.3.2 Size Specifications of Vertical Passbook

L1

L3

L3

L4

L6

L5

L5

L2

Printable area

Printable area

L7

Figure 6-4 Vertical passbook printable area

Dimension

Min Max

L1

passbook width

65 mm

280 mm

L2

passbook length

85 mm

220 mm

L3

left, right margin width

2 mm

/

L4

top margin bottom margin

4 mm

/

L5

passbook centre joint margin width

7 mm

/

L6

bottom margin

6 mm

/

L7

The thickness difference of the right and the left sheets

/ 1.2

mm

Paper weight

90 g/m

2

100

g/m

2

multi-page passbook

/ 3.0

mm

single page passbook or ledger card

0.18 mm 0.28 mm

Paper

thickness

passbook cover

0.18 mm 0.45 mm

- 34 -

Summary of Contents for BP-1000K (Model B)

Page 1: ...User s Manual BP 1000K Model B...

Page 20: ...BP 1000K User s Manual Figure 3 8 Tearing the tractor paper 16...

Page 44: ......