169

JOHNSON CONTROLS

FORM 201.21-NM4 (616)

169

JOHNSON CONTROLS

7

NUMBER OF COMPRESSORS TO START

GENERAL

The number of compressors to start control logic varies

between the standard and optional high IPLV chillers.

Standard IPLV chiller control utilizes sequential logic

that requires the micro to start 1 compressor at a time

and only add a compressor when all running compres-

sors reach maximum speed. Optional High IPLV

chillers have control algorithms that provide “smart”

anticipatory control to determine how many

compressors need to be started to satisfy the current

load. The “smart” logic is capable of reducing short

cycling, and reducing loading time on a hot water start,

and starting all compressors at the same time.

STANDARD IPLV

The standard IPLV control always starts a single

compressor under all circumstances as the first step

of loading. The Chiller Control Board does not make

decisions on the number of compressors to start based

on chilled liquid temperatures and prior compressor

operation when starting the chiller. An additional

compressor is only started when the lead compressor

has reached maximum speed and cooling requirements

are not satisfied.

OPTIONAL OPTIMIZED HIGH IPLV

On optimized IPLV chillers, the Number of

Compressors to Start Logic will be used to determine

how many compressors should be run when the unit

starts from the all compressors stopped state. This

routine will try to run all the compressors unless it is

determined that less will be needed due to light load.

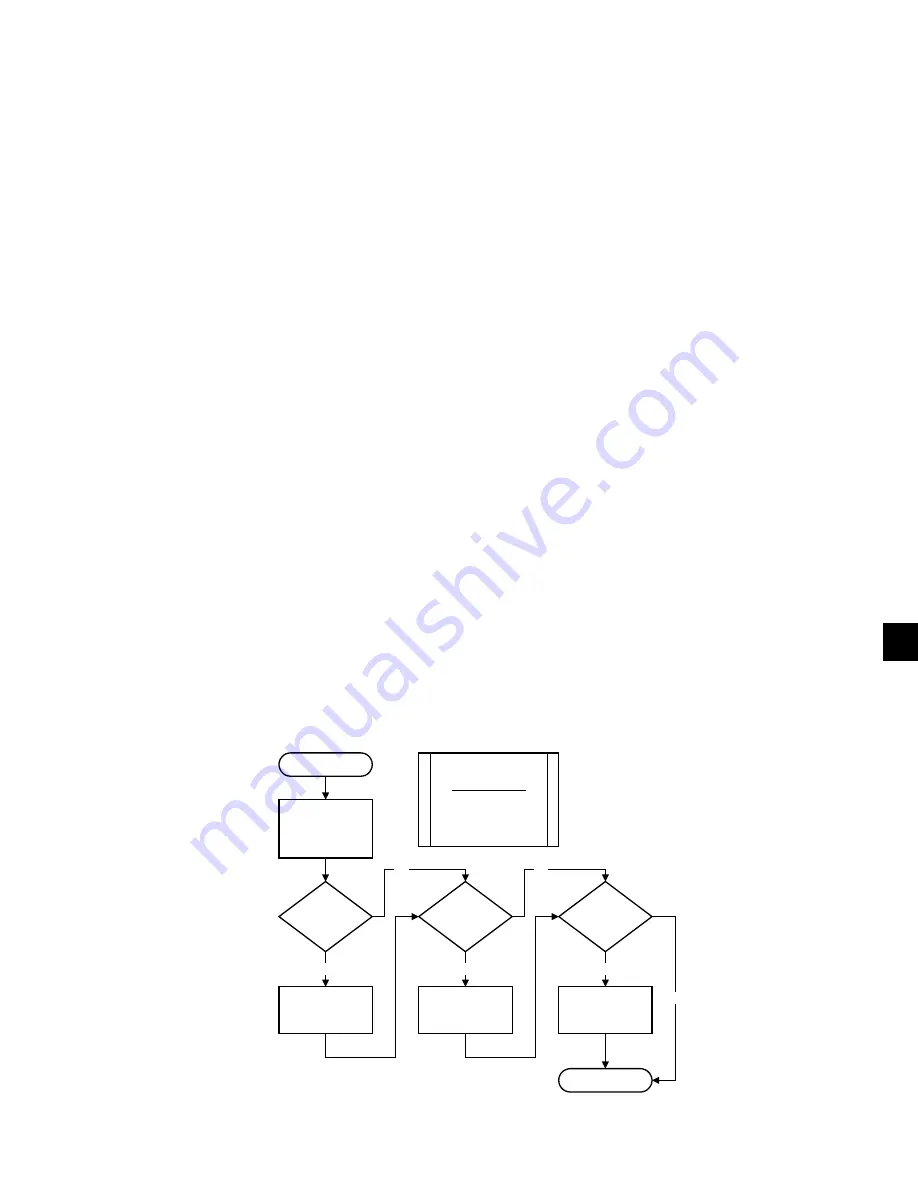

The first step in the sequence is for the micro to set the

number of compressors to start equal to the number of

compressors in the chiller. The micro will look at two

prior conditions relating to the compressor operating

time the previous time it ran and how long the last

compressor has been off along with two indicators

of chilled liquid load requirements (rate of change of

chilled liquid temperature and deviation from setpoint.).

Temperature deviation is the amount of error compared

to the setpoint high limit (Se CR). Based on this

information, the micro will then determine the number of

compressors to start. The flowchart in FIG. 36 describes

the compressor starting decision process.

It is desirable to run as many compressors as possible for

increased efficiency. Optimized logic will keep as many

compressors on line and reduce speed in an effort to

optimize the use of the entire evaporator tube surface.

NUMBER OF COMPS

TO START LOGIC

NUMBER OF COMPS TO

START

REDUCTION TABLE

4 COMPS -> 3 COMPS

3 COMPS -> 2 COMPS

2 COMPS -> 1 COMP

1 COMP -> 1 COMP

SET NUM COMPS

TO START = NUM

COMPS IN UNIT

LAST RUN TIME

< 5 MIN ?

YES

REDUCE NUM COMPS

TO START PER

REDUCTION TABLE

OFF TIME

< 5 MIN ?

YES

REDUCE NUM COMPS

TO START PER

REDUCTION TABLE

NO

CONTINUE

LCHLT RATE

< 3 °F/MIN AND

LCHLT < CR+5°F?

NO

YES

REDUCE NUM COMPS

TO START PER

REDUCTION TABLE

NO

FIG. 36 - NUMBER OF COMPRESSORS TO START

LD10626