TEC20x6(H)-4 and TEC20x6H-4+PIR Series Wireless Thermostat Controllers with Dehumidification

Capability, Fan Control, and Occupancy Sensing Capability

16

Configuring the Wireless Mesh Network

Settings

Use the following process to configure the wireless

mesh network.

1.

Select a

PAN ID

and

Channel

. Use these same

values for every TEC Wireless Thermostat

Controller (and the associated TEC20 Coordinator)

on the same wireless mesh network. See Table 6.

2.

Select a

Com Address

for each TEC Wireless

Thermostat Controller (1 to 254). This address

must be unique to each TEC Wireless Thermostat

Controller on the same wireless network (that is,

unique to the

PAN ID

/

Channel

combination). See

Table 6.

After configuring the wireless mesh network settings,

refer to the

TEC20xx-4 and TEC20xx-4+PIR Series

Wireless Thermostat Controller System Technical

Bulletin (LIT-12011596)

for directions on integrating the

TEC Wireless Thermostat Controllers and TEC20

Coordinator with a supervisory controller.

Dehumidification (TEC2036[H]-4, TEC2036H-4+PIR,

TEC2056[H]-4, and TEC2056H-4+PIR Models Only)

Upon detection of room humidity above the adjustable

humidity setpoint as sensed by the integral humidity

sensor, dehumidification activates.

Note:

Dehumidification operation functions only in the

Cooling mode; dehumidification operation does not

function in either the Off or the Heating mode.

Note:

A central network command can globally

lock out dehumidification operation to all thermostat

controllers.

If the room temperature resides in the deadband

between the Heating and Cooling setpoint:

•

the thermostat controller forces the fan to low

speed

•

the chilled water valve opens to the specified

maximum value set by

CoolMax

•

the thermostat controller stages Heating to

maintain the room temperature at the Cooling

setpoint, as sensed by the thermostat controller

If the room temperature falls below the current Heating

setpoint, the thermostat controller disables

dehumidification operation.

If the thermostat controller is in Cooling demand:

•

the chilled water valve opens to 100%

•

the thermostat controller stages Heating to

maintain the room temperature at the Cooling

setpoint, as sensed by the thermostat controller

If the thermostat controller is in Cooling demand and

the room temperature rises 2F°/1C° above the Cooling

setpoint, the thermostat controller automatically

disables dehumidification operation. Likewise, if the

thermostat controller is in Cooling demand and the

room temperature falls below the current Heating

setpoint, the thermostat controller disables

dehumidification operation.

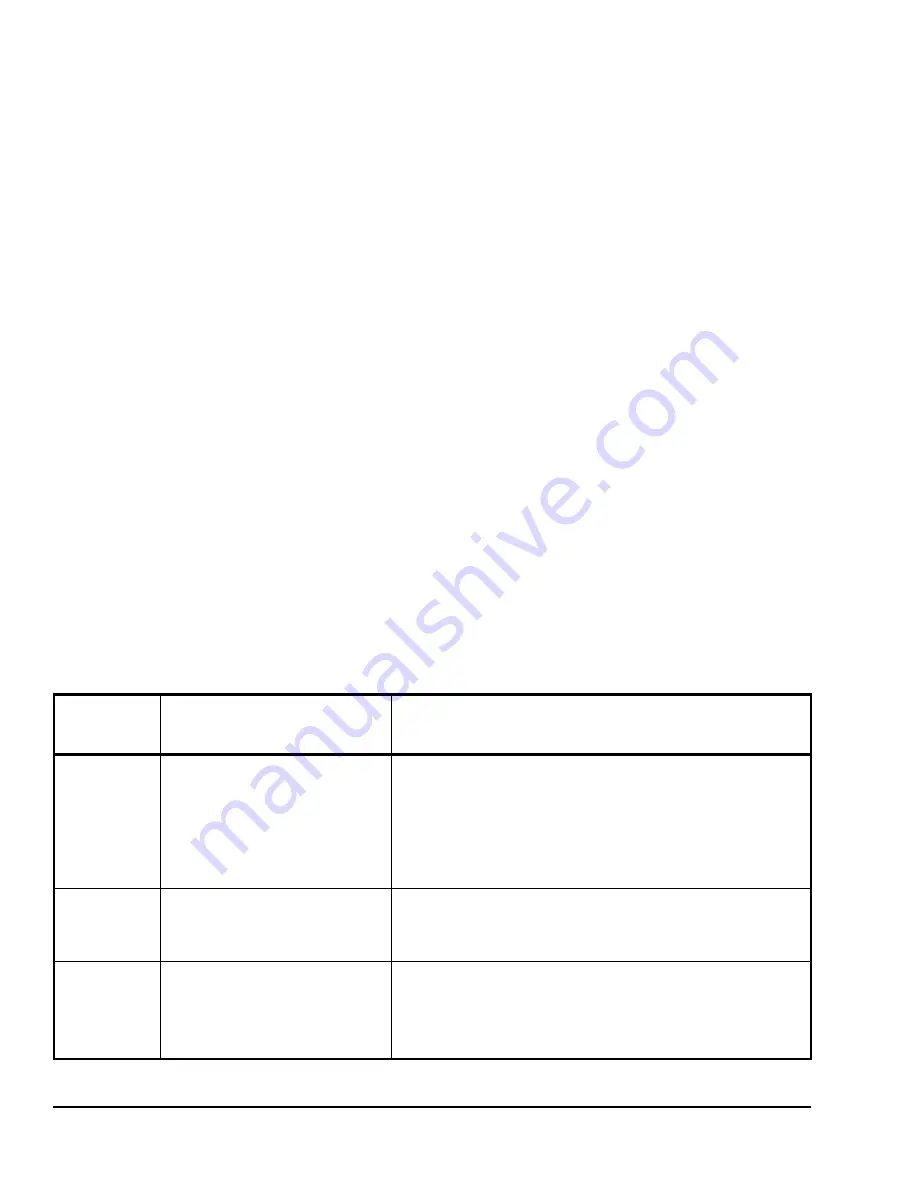

Table 6: Installer Configuration Menu

(Part 1 of 8)

Parameter

Appearing

on Display

Description and Default

Selection Options

Pswrd

Sets the protective access

password to prevent unauthorized

access to the Installer Configuration

Menu.

Default:

0

Note:

The default setting does not

lock out access to the Installer

Configuration Menu.

Range:

0

to

1,000

Com addr

Wireless address at the thermostat

controller; Default:

254

Range:

000

to

254

Addresses of each item on the wireless bus must be uniquely

numbered, increasing from 1.

Note:

Setting this parameter to 0 disables the function.

PAN ID

Sets the Personal Area Network

Identification (PAN ID) of the

wireless network. All devices on a

network must have the same

PAN ID setting to communicate with

each other. Default:

0

Range:

0

to

500

Note:

Setting this parameter to 0 disables the function.