FRICK

®

QUANTUM

™

LX/HD RETROFIT

INSTALLATION INSTRUCTIONS

090.040-I (MAR 2012)

Page 3

INSTRUCTIONS

NOTE: Before proceeding, read the instructions for "Proper

Installation of Electronic Equipment in an Industrial Envi-

ronment" on page 7.

1.

Push

[STOP]

key to shut down the unit. Open the

disconnect switch for the compressor motor starter

and (if applicable) oil pump motor starter.

2.

Close the discharge, and liquid injec tion (if applicable)

service valves.

3. SLOWLY

vent the separator to low-side system pres sure

using the suction check valve bypass. Close suction valve

and suction check valve bypass.

NOTE: Recover or transfer

all refrigerant vapor in accordance with local ordinances

before opening to atmosphere.

The separator

MUST

be

equalized to atmospheric pressure.

Oil-entrained refrigerant may va-

porize, causing a separator pressure

increase. Repeat venting and recov-

ery procedure if neces sary.

4.

Drain the oil from the oil separator if an oil separator

temperature probe well is to be installed.

5.

Remove the existing panel from the compressor package.

DO NOT CUT WIRES OR TUBING LINES.

They will be used

to connect to the new panel.

6.

If converting from an RWB II to a

QUANTUM

™

LX/HD

,

remove the front panel assembly. Remove wires on the I/O

board which run from the micro enclosure to the junction

box. Remove the analog wires from the FRK-1 board. Remove

ground, +5VDC, ±12VDC and +24VDC from the FRK-1, SBC

and I/O boards. Be sure all of the above wires are labeled

because all except ±12VDC and +24VDC will be connected

to the

QUANTUM

™

LX/HD

.

7.

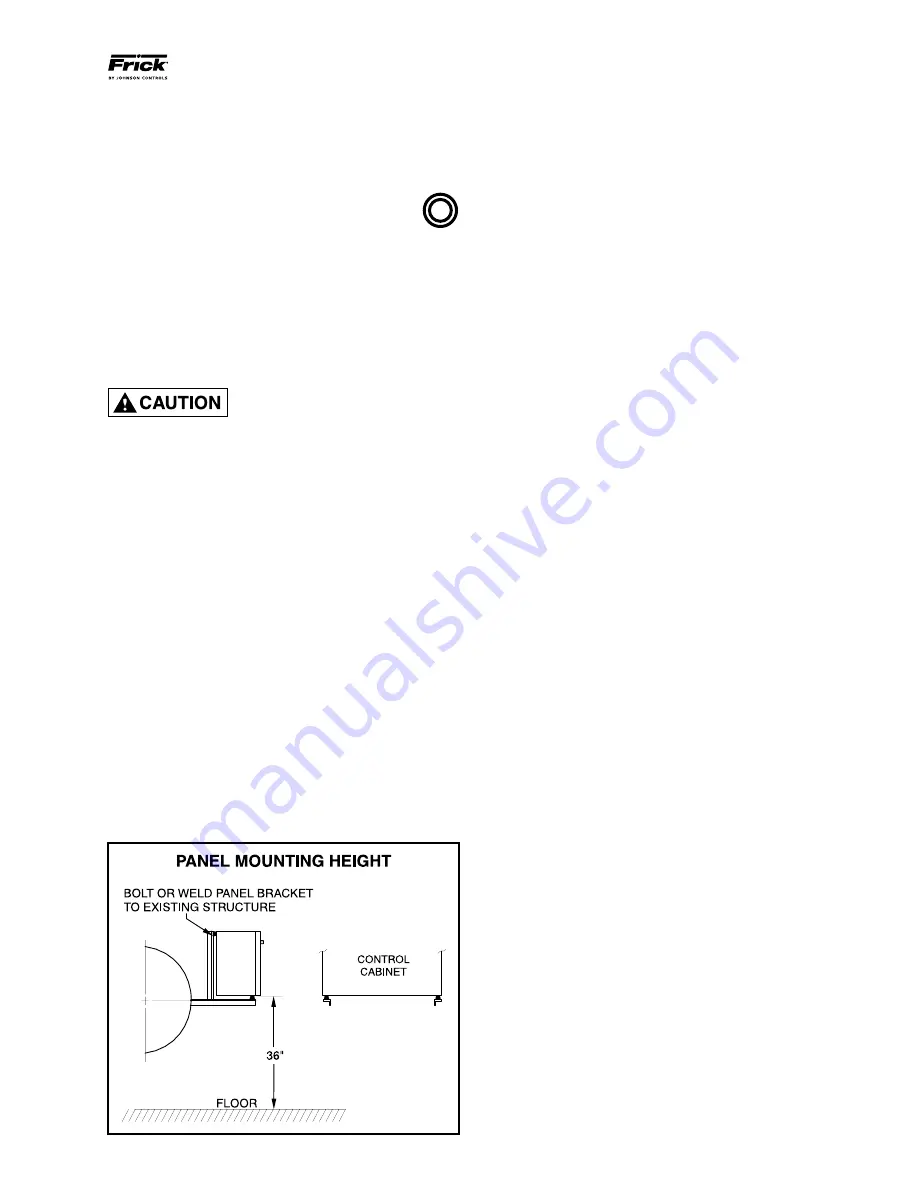

Remove existing thermometers, temperature switches

and pressure switches (if applicable) from the compressor

package.

8.

Mount the

QUANTUM

™

LX/HD

panel on the compressor

package by bolting the panel to the existing panel mounting

structure. It may be necessary to weld new panel mounting

brackets to the screw compressor package to accommo-

date the proper panel height. If so,

DO NOT WELD TO THE

PRESSURE VESSEL.

Weld only to existing mounts or other

structural material.

DO NOT WELD WITH THE CONTROL

PANEL IN PLACE.

Welding currents can cause damage to

the electronic components. Refer to the PANEL MOUNTING

HEIGHT diagram below.

9.

Install the temperature probe wells at the locations indi-

cated on the TRANSDUCER CONNECTION DIAGRAM. Existing

connections may require reducers to fit the new temperature

wells. Some of the required locations may not have a con-

nection available and will require cutting a hole and welding

in a connection for the temperature well. Seal all threaded

connections to prevent leaks.

10.

Place silicone heat transfer compound on the tip of the

temperature probes and install them in the temperature wells.

11.

Run separate electrical conduit between the control

panel and the temperature probe electrical boxes.

DO NOT

RUN THE TEMPERATURE PROBE WIRING WITH THE AC

CONTROL WIRING.

12.

The wiring between the control panel and the tempera-

ture probes must be shielded twisted-pair wire. Belden part

number 8761 or equivalent is recommended.

13.

Refer to the panel wiring diagrams in the S70-200 IOM

and connect the white wire of the twisted pair to the nonblack

temperature probe wire. The temperature probe wire colors

may vary on this wire. Connect the black wire of the twisted

pair to the temperature probe black wire. Cut off the shield

wire on the temperature probe end and place tape or heat

shrink tubing around the exposed shield so that it will not

come in contact with the electrical box.

14.

Connect the shield wire of the twisted pair to the control

panel ground block in the control panel.

15.

Connect the white and black twisted-pair wires to the

microprocessor board, as shown on the panel wiring dia-

grams in the IOM.

16.

Install stainless steel tubing from the points indicated in

the TRANSDUCER CONNECTION DIAGRAM to the pressure

transducer pressure block located behind the control panel.

Properly brace all pressure lines so that excessive vibration

will not cause transducer error.

DO NOT PLACE VALVES

BETWEEN DISCHARGE OR OIL LINES AND THE PRESSURE

TRANSDUCER.

17.

Refer to the panel wiring diagrams in the Maintenance

manual (090.020-M or 090.040-M) and connect the red,

black, and white wires of the pressure transducers to the

QUANTUM

™

LX /HD

analog board. The shield of the transducer

cable is grounded inside the transducer and should not be

grounded inside the cabinet.

18.

Determine if there is a slide valve potentiometer on the

slide valve indicator assembly. If a potentiometer is provided,

it should be 1,000 OHMS single turn or 10,000 OHMS ten

turn with a calibration resistor. If a potentiometer is not

provided, contact Frick for ordering proper potentiometer

and drive assembly.

19.

Run separate electrical conduit between the control panel

and the slide valve indicator assembly.

DO NOT RUN SLIDE

VALVE WIRING WITH AC CONTROL WIRING.

20.

The wiring between the control panel and the slide valve

indicator must be shielded twisted-three wire. Belden part

number 8770 or equivalent is recommended.