Component

Internal Size

Resistance

Component

Internal Size

Resistance

(mm)

Factor

(mm)

Factor

Flue Blocks

197 x 67

0.85 per meter

135

O

Bend

100 mm pipe

0.61 per

231 x 65

0.65 run

125 mm pipe

0.25 fitting

317 x 63

0.35

150 mm pipe

0.12

140 x 102

0.60

197 x 67

0.30

200 x 75

0.60

231 x 65

0.22

183 x 90

0.45

317 x 63

0.13

Pipe

100

0.78

Raking block

Any

0.30 per block

125

0.25

150

0.12

Adaptor block

Any

0.50

Chimney

213 x 213

0.02

Terminal

100 mm ridge

2.5

125 mm ridge

1.0

90

O

Bend

100 mm pipe

1.22 per

150 mm ridge

0.48

125 mm pipe

0.50 fitting

100 mm GCI

0.6

150 mm pipe

0.24

125 mm GCI

0.25

150 mm GCI

0.12

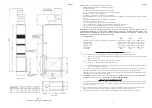

Table 3

Resistance factors for use in calculating equivalent heights

Appliance

Inlet

Flue

Outlet

Resistance (K

i

)

Resistance (K

o

)

100 mm dia spigot

2.5

100 mm flue

2.5

125 mm dia spigot

1.0

125 mm flue

1.0

150 mm dia spigot

0.48

150 mm flue

0.48

Table 4

Inlet and outlet resistance

d.

Worked Calculation Example:

A warm air unit with a 100 mm diameter flue spigot, fitted with a pre-fabricated flue system leading to a

ridge tile (refer Fig. 2):

From table 4:

K

ia

Inlet resistance of actual flue

= 2.5

K

oa

Outlet resistance of actual flue

= 2.5

K

ie

Inlet resistance of equivalent flue

= 2.5

K

oe

Outlet resistance of the actual flue

= 2.5

From table 3:

Other resistances of actual flue:

Terminal

= 2.5

Pipe bend ( 2 x 0.61)

= 1.22

Pipe (4 x 1m @ 0.78)

= 3.12

(5 x 0.3m @ 0.78)

= 1.17

Sum K

= 8.01

Equivalent height :

From the formula

(2.5 + 2.5)

H

e

= 6.2 x ______________________

(2.5 + 2.5) - (0.78 x 6.2) + 8.01

H

e

= 3.793

This flue exceeds 1.0m equivalent height and is therefore satisfactory.

5

ZZ602/6

ZZ602/6

14

8.12

LIMIT SWITCH REMOVAL:

8.12.1 Ensure that the electrical supply is isolated.

8.12.2 Remove the appliance central front door.

8.12.3 Disconnect the 2 BLUE conductors from the Interrupter at the Multifunctional Control.

8.12.4 Release the 2 x screws securing the Fan Delay Control cover, and withdraw the cover.

8.12.5 Release the 2 x screws securing the Temperature Probe assembly, and withdraw the assembly.

8.12.6 Remove the Temperature Probe from the terry clip, and withdraw the probe from the assembly having first

removed the grommet.

8.12.7 Release the 2 x screws securing the Limit Switch, and withdraw the control from the appliance.

8.12.8 Refitment or replacement is in reverse order.

8.13

HEAT EXCHANGER ACCESS:

8.13.1 Remove the upper and central front doors.

8.13.2 Remove the Burner and Controls assembly as detailed in para 8.2

8.13.3 Release the 4 x securing screws and remove heat exchanger access plate and gasket from the front of the draught

diverter.

8.13.4 Release the nuts securing the baffle retaining plate, and remove the retaining plate and washers.

8.13.5 Remove the heat exchanger baffles.

8.13.6 Reassembly is in reverse order.

NOTE:

When reassembling, ensure that the baffle is pushed fully home and access cap is fully sealed. In the event of heat

exchanger replacement being necessary, contact Johnson and Starley Service Department.

9.

DEFECT DIAGNOSIS

9.1

IMPORTANT: If an electrical defect occurs after installation of the appliance; preliminary earth continuity,

polarity, and resistance to earth checks should be carried out with a multimeter. On completion of any

maintenance/fault-finding task that has required the breaking and remaking of electrical connections, then

checks of continuity, polarity, and resistance to earth must be repeated.

9.2

WARNING:

When purging or checking gas supplies, ensure that the ventilation to the room or cupboard is

adequate, and that all naked lights are extinguished.

SYMPTOM

POSSIBLE CAUSE

REMEDY

a. Pilot will not light.

i.

No gas supply to heater.

Check for gas at inlet pressure test

point on multifunctional control.

ii.

Gas supply pipe not purged.

Purge gas supply pipe in accordance

with BS 6891.

iii

Pilot orifice restricted.

Clear pilot orifice or replace pilot

injector.

iv.

Piezo system faulty.

Check igniter, lead, and electrode.

v.

Limit Switch has operated

Relight Pilot or replace Limit Switch

vi

Limit Switch connections

Check connections and wiring.

damaged

b. Pilot lights but goes

i.

Connection between thermo-

Check connection is secure.

out on releasing START

couple and Multifunctional

button during initial

Control not secure.

light-up, or after

normal operation.

ii.

Faulty power unit on gas

Replace Multifunctional Control.

control.

iii.

Faulty thermocouple.

Replace Thermocouple.

iv.

Pilot flame too small.

Adjust.

v.

Pilot orifice restricted.

Replace Pilot injector

vi.

Limit control has operated

Relight Pilot or replace Limit Switch.