5.

INSTALLATION REQUIREMENTS

5.1

FLUES (see British Standards BS5440 Pt.1 Flues)

5.1.1

All joints shall be soundly sealed.

5.1.2

The flue should be kept as short and warm as possible.

5.1.3

Sufficient support brackets shall be installed to bear the weight of the total flue system.

5.1.4

The spigot connection of the heater draught diverter will accept internally the spigot end of a non-asbestos flue

to BS567 or twin wall metal flue to BS715 of nominal diameter as specified in para 1.2.

5.1.5

A split collar should be fitted to provide for flue maintenance or inspection.

5.1.6

The flue shall be in accordance with the Building Regulations and British Gas Materials and Installations

specification 3rd edition) with regard to clearance and shielding from combustible materials.

5.1.7

All materials shall be in accordance with local gas region and Building Regulations requirements.

5.1.8

The flue should run as vertically as possible. Horizontal runs should be avoided if at all possible and any

directional change should be as gentle as possible. If there is any doubt about the flue configuration, the

equivalent flue height should be determined (see 5.1.10).

5.1.9

If the appliance to be fitted is a replacement, the old appliance should be checked for signs of spillage prior to

commencement of the installation and appropriate action taken, (i.e. check flue system and renew as necessary).

5.1.10 It is recommended that at least 600mm of vertical flue should be provided from the top of the draught diverter

(for new installations this shall be incorporated into the flue design). However, when carrying out replacement

installations, an existing flue system may be encountered, where the vertical flue above the appliance to the first

bend is less than 600mm. In the first instance, the installer must judge whether this distance can be achieved

practicably by some means. Where this is not practicable, the existing flue system may be used, providing there is

no evidence of spillage from the old appliance (see 5.1.9 above). Every effort must be made, however, to ensure

that the existing flue complies in every other way to BS 5440 Part 1, including the visual inspection, flue flow and

spillage test described in 4.3.2 of the above standard. Flue configurations may be assessed in terms of equivalent

vertical height - details are given in 5.1.11. For air heaters, the minimum equivalent vertical height is 1 metre. The

installer must make a judgement based on his knowledge and experience and the examination and testing

described above as to whether an existing flue system can be used.

Note:

Ventilation of the compartment, room or internal space in which the appliance is to be installed must be checked

for compliance with the requirements of BS 5440 Part 2 ( Ref. Section 3 of these instructions) and upgraded as

necessary.

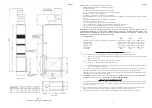

5.1.11

Calculation method for flue sizing: ( from BS 5440: Part 1, Appendix A)

a.

This appendix provides a procedure for estimating whether a given flue design is likely to ensure full

clearance of combustion products.

b.

The procedure is based on calculating the ‘equivalent height’ of the flue under consideration, i.e. that

height of the straight vertical circular flue pipe of specific size which will produce the same flow rate as

the flue under consideration. The equivalent height is calculated from the formula:

(K

i

+ K

o

)

e

H

e

= H

a

x ____________________

(K

i

+ K

o

)

a

- K

e

H

a

+ Sum K

where:

H

e

is the height of the equivalent flue;

H

a

is the vertical height of the actual or proposed flue;

K

i

is the inlet resistance of the flue;

K

o

is the outlet resistance from the flue;

subscript e refers to the equivalent flue diameter;

subscript a refers to the actual or proposed flue diameter;

K

e

is the resistance per unit length of the equivalent flue;

Sum K is the resistance (other than the inlet and outlet resistance) of the actual or proposed flue.

Note:

K and Sum K are obtained from Table 3. K

o

and K

i

are obtained from Table 4.

c.

Table 3 gives resistance factors for common flue components for use in the formula. Table 4 contains the

appropriate inlet and outlet flue resistances. (

The flue is likely to be satisfactory if its equivalent

height exceeds 1m

).

ZZ602/6

4

ZZ602/6

15

c. Main burner lights

i.

Loose electrical connection

Check connections.

but fan fails to run

Fan Delay Control.

after approx. 3 min.

ii.

Fan Delay Control set incorrectly.

Check for correct settings.

iii.

Faulty fan assembly.

Replace, taking care not to damage

impeller.

iv.

Faulty Fan Delay Control.

Replace.

v.

Burner pressure setting incorrect.

Adjust Burner pressure.

d. Main burner operating

i.

Gas rate or burner pressure

Check gas rate and burner pressure

intermittently

setting high.

setting.

with fan running.

ii.

Temperature rise excessive.

Adjust fan speed or gas rate accordingly.

iii.

Air filter or return air path

Check filter is clean and air path is clear.

restricted.

iv.

Excessive number of outlets

Open additional outlets.

closed.

v.

Spillage of flue gases.

Carry out spillage test and rectify.

e. Main burner operating

i.

Gas rate or burner pressure

Check gas rate and burner pressure

with intermittent

setting too low.

setting.

fan operation.

ii.

Fan Delay Control set incorrectly.

Check for correct settings.

f. Fan runs for excessive

i.

Fan Delay Control set incorrectly.

Check for correct settings.

period or operates

intermittently after

main burner shuts down.

g. Noisy operation.

i.

Gas pressure too high.

Check burner pressure setting.

ii.

Noisy fan motor.

Replace fan assembly.

iii.

Fan speed setting too high.

Adjust fan speed.

j. Pilot alight but main

i.

Mains electrical supply not

Check mains supply.

burner not igniting.

connected to heater.

ii.

Controls not demanding heat

Check that time control and

thermostat are operating correctly.

iii.

6.3A fuse failed.

Replace. If failure occurs again, check

wiring for short circuits.

iv.

Loose connection to thermostat,

Check connections.

Limit Switch , time control,

Multifunctional Control

or transformer.

v.

Transformer open circuit.

Check with test meter and replace

transformer.

vi.

Multifunctional control faulty.

Replace Multifunctional control.

vii.

Limit Switch faulty.

Short circuit control and replace if

necessary.

viii. Room thermostat or external

Fit temporary loop in heater thermostat

wiring faulty.

socket. If heater ignites, external circuit

or room thermostat is faulty.