ZZ602/6

Fig. 6

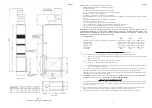

JU Series Air Heaters Principle Dimensions

17

2

ZZ602/6

6Installation shall be in accordance with the current editions of:-

Building Standards (Scotland) (Consolidation) Regulations.

Building Regulations.

Gas Safety (Installation and Use) Regulations (as amended).

BS 7671 Institute of Electrical Engineers (I.E.E.) Wiring Regulations.

BS 5440 Pt. 1 (Flues for Gas Appliances).

BS 5440 Pt. 2 (Installation of ventilation for gas appliances)

BS6230 Installation of Gas Fired Forced convection Air Heaters for Commercial and Industrial space heating (2nd family

gases).

British System Design Manual “Gas Fired Warm Air Heating”.

Model and Local Authority Bye-laws.

IM/2

Purging procedures for non-domestic gas installations.

IM/5

Soundness testing procedures for industrial and commercial gas installations.

IM/11 Flues for commercial and industrial gas fired boilers and air heaters.

IM/16 Notes on installation of pipework (excluding domestic installations of 25mm and below).

IMPORTANT: STATUTE LAW DEFINES THAT ALL GAS APPLIANCES MUST BE INSTALLED BY

COMPETENT PERSONS, (i.e. CORGI REGISTERED INSTALLERS) IN ACCORDANCE WITH THE GAS

SAFETY (INSTALLATION AND USE) REGULATIONS (CURRENT EDITION). FAILURE TO COMPLY WITH

THESE REGULATIONS MAY LEAD TO PROSECUTION.

1.2

GENERAL DATA

JU78

JU117

JU156

Appliance height (excluding air discharge top or swivel heads)

1830mm (72in) 1830mm (72in) 1830mm (72in)

Appliance width

375mm (14.8in) 525mm (20.7in) 675mm (26.2in)

Appliance depth

778mm (30.6in) 778mm (30.6in) 778mm (30.6in)

Appliance weight

110kg (242lb)

140kg (308lb)

220kg (484lb)

Flue diameter

125mm (5in)

150mm (6in)

150mm (6in)

Fuse rating

T6.3A

T6.3A

T6.3A

2.

HEATER COMPARTMENT AND CLEARANCES

(See BS6230)

2.1

When a heater is fitted into a compartment, the following minimum clearances must be maintained:

2.1.1

12mm (0.5in ) from rear, and a side fitted with a blanking plate, allowing extra space if a gas supply pipe enters the

appliance from this side.

2.1.2

600mm (24 in) from a side fitted with a louvre side return panel.

2.1.3

230mm ( 9 in ) from the front for combustion air supply.

2.1.4

Consideration should also be given to the space required for the removal and replacement of the filter tray and the

entry of the gas and electrical supplies.

2.2

For service access, a minimum of 750mm (30ins) is required at the front of the heater. Space must also be allowed, in a

compartment installation, to permit the removal of the heater. Where clearances between the appliance and the

compartment are less than 75mm, the internal surface of the compartment must be lined with non-combustible material.

The compartment must be of a fixed rigid structure.

2.3

IMPORTANT:

When the heater is installed in a compartment, the ‘

SAFETY

’ label supplied with the heater

MUST BE

AFFIXED

in a prominent position on the

INSIDE

of the

COMPARTMENT DOOR

.

3.

VENTILATION AND COMBUSTION AIR

3.1

When the air heater is free standing or ducted, but in an open area, there must be a adequate supply of air for combustion

in accordance with BS 6230 Clause 12.1.1. The openings should be sited so that they cannot be easily blocked (refer to

BS 6230 Clause 12.1.3).

3.2

Where natural ventilation is used for compartment or plant rooms, suitable permanent openings at low and high level,

communicating directly with outside air, shall be provided in accordance with BS 6230 Clause 12.1.5.

3.3

If the installation includes more than one heater, the ventilation requirements of BS 6230 must be observed.