12

3. Rotate scale

counterclockwise

all the way until

it stops at “0”.

4. Loosen lock handle (A

2

).

5. Use feed handle (B, Figure 8-1) to lower bit to

desired depth based on reference mark.

6. Hold feed handle in position, and tighten lock

handle (A

2

).

7. The bit will now stop at the marked depth

when feed handle is rotated.

8. To release depth stop, loosen lock handle (A

2

).

8.5

Powerfeed operation

See Figures 8-1 and 8-2.

1. Select appropriate spindle speed range (lever

C on clutch model; reposition belt on step

pulley model).

2. Select downfeed rate (D).

3. Set depth of cut (

sect. 8.4

).

4. Tighten handle (A

2

) to secure setting.

5. Loosen powerfeed locking knob (E).

6. Turn on spindle and adjust speed knob (H) to

desired RPM.

7. Pull feed handle (B) outward (away from head)

to engage powerfeed.

8. Once downfeed has reached pre-set depth,

the trip will release and spindle will retract.

9. To stop feed before cycle has ended, push

feed handle (B) toward head.

NOTE: Set downfeed dial (D) to “0” when not using

powerfeed.

8.6

Quill retraction lock

The quill can be held in the down position and

prevented from retracting, to facilitate removal of

chuck arbor or for cleaning.

1. Loosen lock handle (A

2

, Figure 8-1).

2. Rotate feed handle (B) to lower spindle to

point at which it is to be locked, and hold feed

handle stationary in this position.

3. Rotate scale (A

1

)

clockwise

all the way until it

stops.

4. Tighten lock handle (A

2

). You can now release

downfeed handle. The quill will remain in this

lowered position until released.

5. To release quill, loosen lock handle (A

2

).

8.7

Drilling recommendations

The following are only general recommendations.

Consult a machinery handbook or contact the

specific tool manufacturer for more detailed

information.

8.7.1

Drilling speeds

The speed of a drill is usually measured in terms of

the rate at which the outer periphery of the tool

moves in relation to the work being drilled. The

common term for this is Surface Feet per Minute

(SFM). The relationship of SFM is expressed in the

following formulas:

SFM = 0.26 X rpm X Drill Diameter (in inches)

RPM = 3.8 x ________SFM__________

Drill diameter (in inches)

In general, the higher the speed the shorter the drill

life. Operating at the low end of the speed range

for a particular material will result in longer life. The

most efficient speed for drill operation depends

upon many variables:

1. Composition and hardness of material.

2. Depth of hole.

3. Efficiency of cutting fluid.

4. Type and condition of drilling machine.

5. Desired quality of hole.

6. Difficulty of set-up.

8.7.2

Drilling feed

The feed of a drill is governed by size of tool and

the material drilled. Because feed rate partially

determines rate of production and also is a factor in

tool life, it should be chosen carefully for each job.

In general, the most effective feeds will be found in

the following ranges:

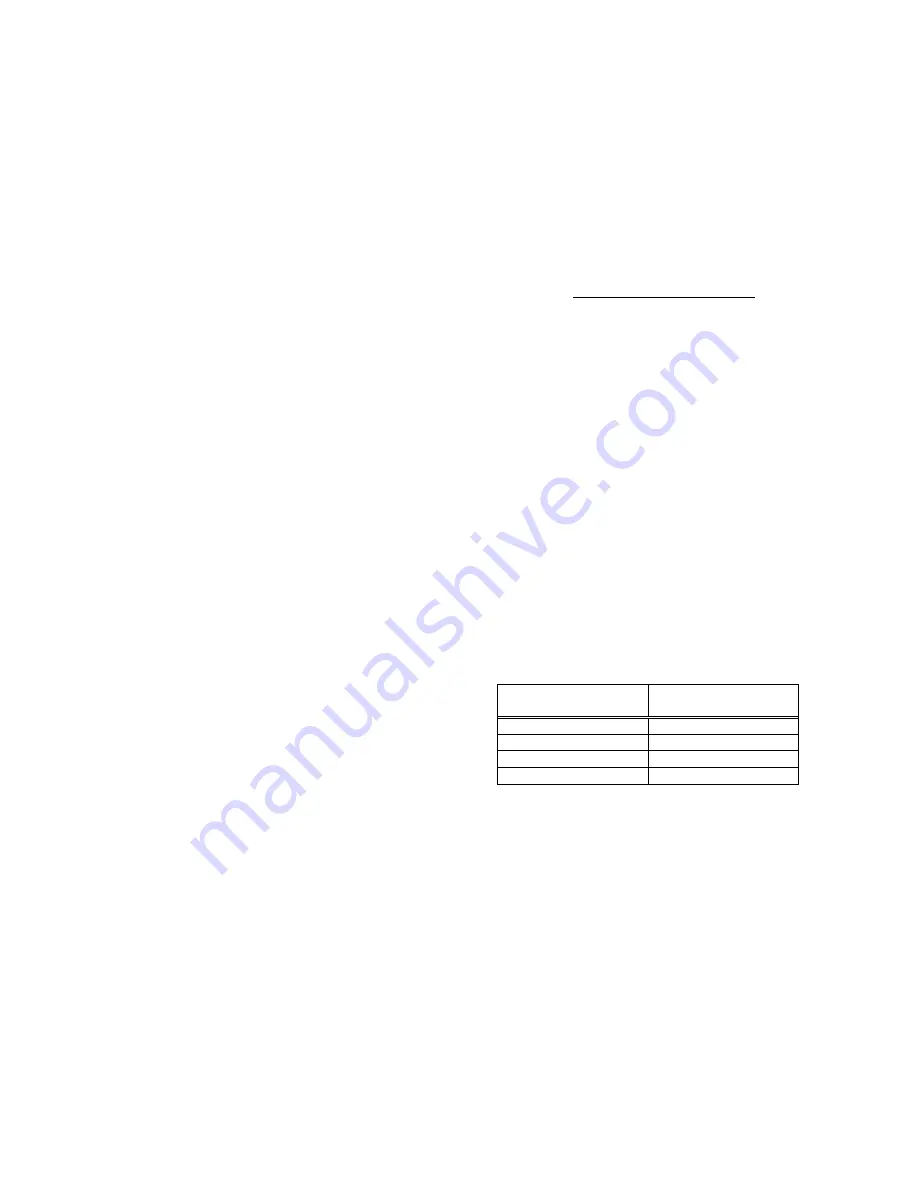

Diameter of Drill

(inches)

Feed per Revolution

(inches)

Under 1/8

0.001 to 0.002

1/8 to 1/4

0.002 to 0.004

1/4 to 1/2

0.004 to 0.007

1/2 to 5/8

0.007 to 0.015

Table 2

8.7.3

Excessive speed/feed indicators

A drill that splits up the web is evidence of too

much feed or insufficient tip clearance at the center

as a result of improper grinding. The rapid wearing

away of the extreme outer corners of cutting edges

indicates that speed is too high. A drill chipping or

breaking out at the cutting edges indicates that

either feed is too heavy or drill has been ground

with too much tip clearance.

Summary of Contents for JDPE-20EVS-PDF

Page 17: ...17 11 1 1 JDPE 20EVSC PDF Clutch Head Assembly Exploded View ...

Page 18: ...18 11 1 2 JDPE 20EVS PDF Step Pulley Head Assembly Exploded View ...

Page 19: ...19 11 1 3 JDPE 20EVS series Electric Box Assembly Exploded View ...

Page 20: ...20 11 1 4 JDPE 20EVS series Down Feed Assembly Exploded View ...

Page 21: ...21 11 1 5 JDPE 20EVS series Column Table Assembly Exploded View ...

Page 27: ...27 12 0 Electrical connections JDPE 20EVS series ...