32

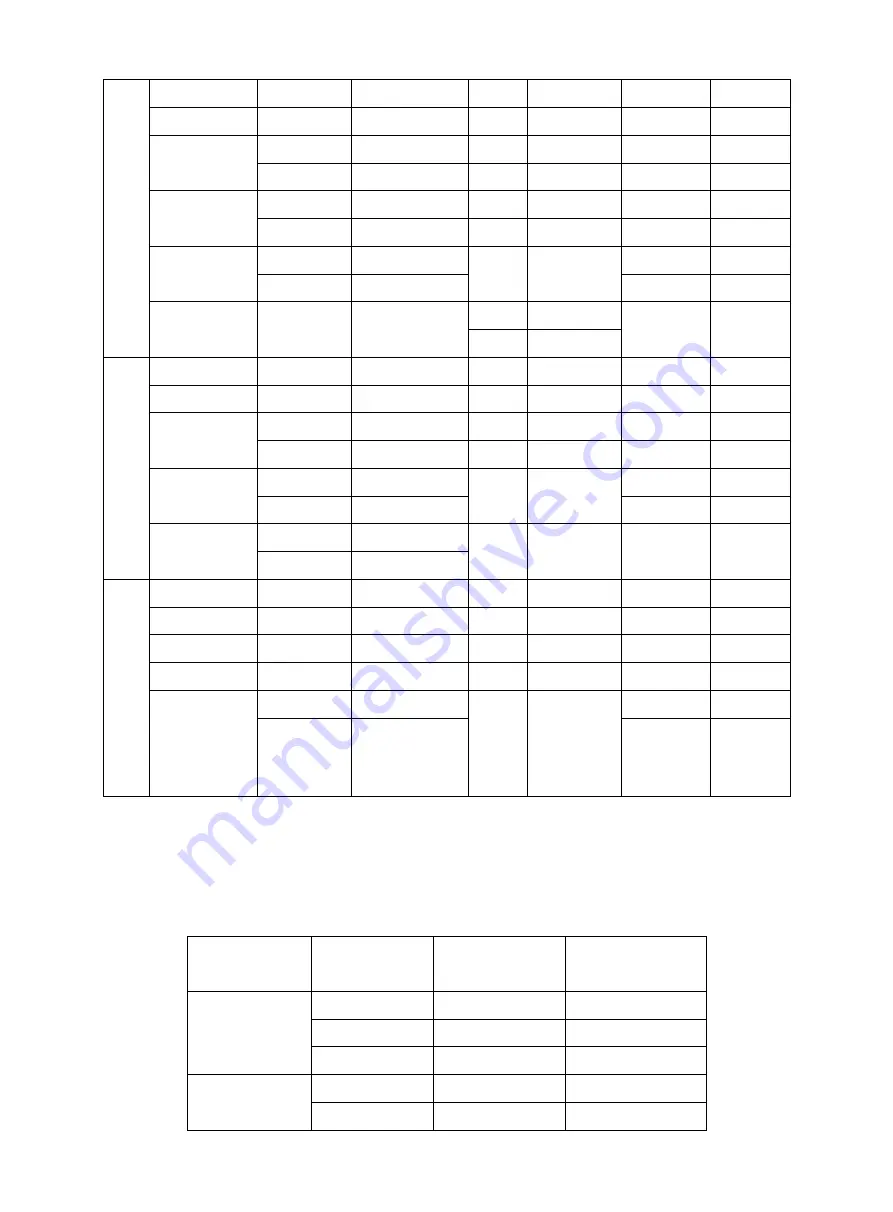

Fillet

weld

in

the

horiz

ontal

posit

ion

2

2

55-65

~

~

3

3.2

100

~

120

~

~

4

3.2

100

~

120

~

~

4

160

~

200

~

~

5

~

6

4

160

~

200

~

~

5

220

~

280

~

~

≥7

4

160

~

200

5

220

~

230

5

220

~

280

~

4

160

~

200

4

160

~

200

4

160

~

220

5

220

~

280

Fillet

weld

in

the

verti

cal

posit

ion

2

2

50

~

60

~

~

3

~

4

3.2

90

~

120

~

~

5

~

8

3.2

90

~

120

~

~

4

120

~

160

9

~

12

3.2

90

~

120

4

120

~

160

4

12

~

0160

~

3.2

90

~

120

4

120

~

160

3.2

90

~

120

4

120

~

160

Fillet

weld

in

the

over

head

posit

ion

2

2

50

~

60

~

~

3

~

4

3.2

90

~

120

~

~

5

~

6

4

120

~

160

~

~

≥7

4

140

~

160

4

140

~

160

~

3.2

90

~

120

4

140

~

160

3.2

90

~

120

4

14

~

0160

4

140

~

160

6.4.2 MIG processing parameters

Table 6-4 CO

2

welding nozzle distance and gas flow

Wire

diameter/mm

Welding

current/A

Nozzle

distance/mm

Gas flow L/min

1.2

100

10

~

15

15

~

20

200

15

20

300

20-25

20

1.6

300

20

20

350

20

20

Summary of Contents for MIG 350P

Page 13: ...11 4 6 2 Separated machine installation Figure 4 3 ...

Page 19: ...17 3 Operation modes Table 5 2 DC MIG operation modes Modes Sketch map 2T 4T ...

Page 20: ...18 Repeat Spot weldin g 5 2 3 Pulse MIG 1 Synergic and Separate ...

Page 22: ...20 2T with initial crater 4T ...

Page 23: ...21 4T with initial segmen t Special 4T pro gram 4T ...

Page 40: ...38 7 Wiring Diagram ...

Page 42: ...40 ...