29

Fan is not working or

abnormal

rotating

speed during welding

· 3 phase power cable is

well connected

·phase loss

· input voltage is too low

· connect well the 3 phase power cable

·solve the power input phase loss

·resume operation after input voltage is back to

normal

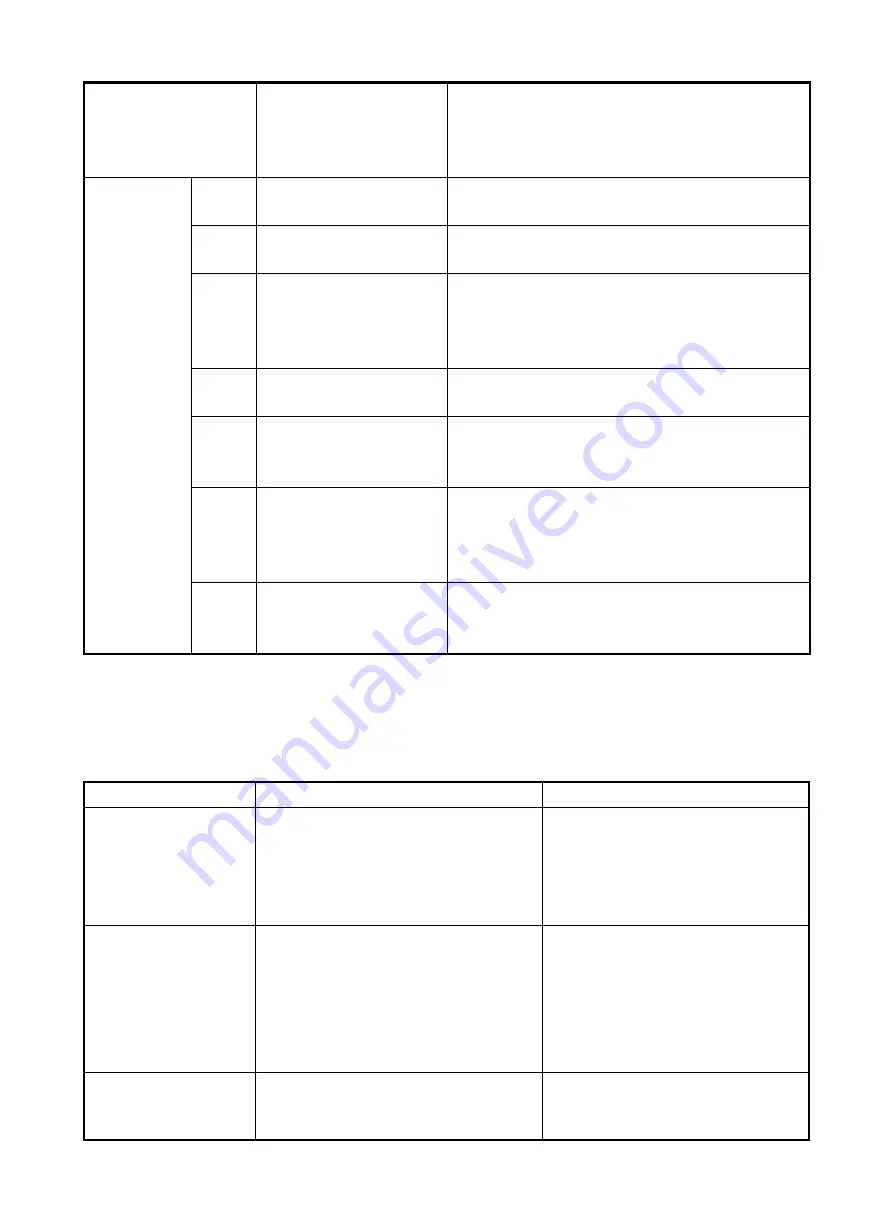

The

left

display shows

“EXX”

,

and

right display

shows“---”

E60

·overheat

protection

(

thermoswitch

)

· Auto recovery after machine is cooled down.

E61

·over-heat

protection

(

temperature probe

)

·Auto recovery after machine is cooled down

E31

· low supply voltage

· failure on auxiliary power

supply

· Machine can resume to work when power grid input

voltage is back to normal.

· replace the new control board or industrial frequency

transformer

E10

·

Over current or failed

power components

· restart the machine; if over-current still exists, please

contact Jasic service man.

E71

·

Failure on water flow

· Please check if there is not enough water in the

radiator and check if water flow is under good

condition.

E70

·

Water cooler over-heat

·

The radiator is not well

connected to the welder

· Radiator is over-heated; stop welding until the

radiator is cooled off and problem is solved.

· Please do checking after turn off the machine; or there

might be danger of electric shock hazard.

E52

·

Wire

feeder

communication failure

· connect tight the control cable; if the problem still

cannot be solved, please contact Jasic service

center.

6.3.2

MIG problems and troubleshooting

Table 6-2 MIG problems and troubleshooting.

Failures or problems

Analysis

Solutions suggested

Machine has no current

output and no failure

· failure on welding loop

· failed current feedback inside the

machine

· please check welding loop and fix the

according problem

· Please contact Jasic service center for

professional solutions.

There is gas and current

output when push torch

trigger, but no wire

feed.

· worn wire feeder control cable

· stuck wire feeder

·failure on wire feeder

· failed machine control board.

· replace or fix the worn wire feeder

control cable.

· make sure wire feeder is not stuck

· fix wire feeder

· replace control board

Welding

current

is

unstable

· inappropriate wire feeder moment knob

adjustment

· please adjust the suitable wire feeder

moment force

Summary of Contents for MIG 350P

Page 13: ...11 4 6 2 Separated machine installation Figure 4 3 ...

Page 19: ...17 3 Operation modes Table 5 2 DC MIG operation modes Modes Sketch map 2T 4T ...

Page 20: ...18 Repeat Spot weldin g 5 2 3 Pulse MIG 1 Synergic and Separate ...

Page 22: ...20 2T with initial crater 4T ...

Page 23: ...21 4T with initial segmen t Special 4T pro gram 4T ...

Page 40: ...38 7 Wiring Diagram ...

Page 42: ...40 ...