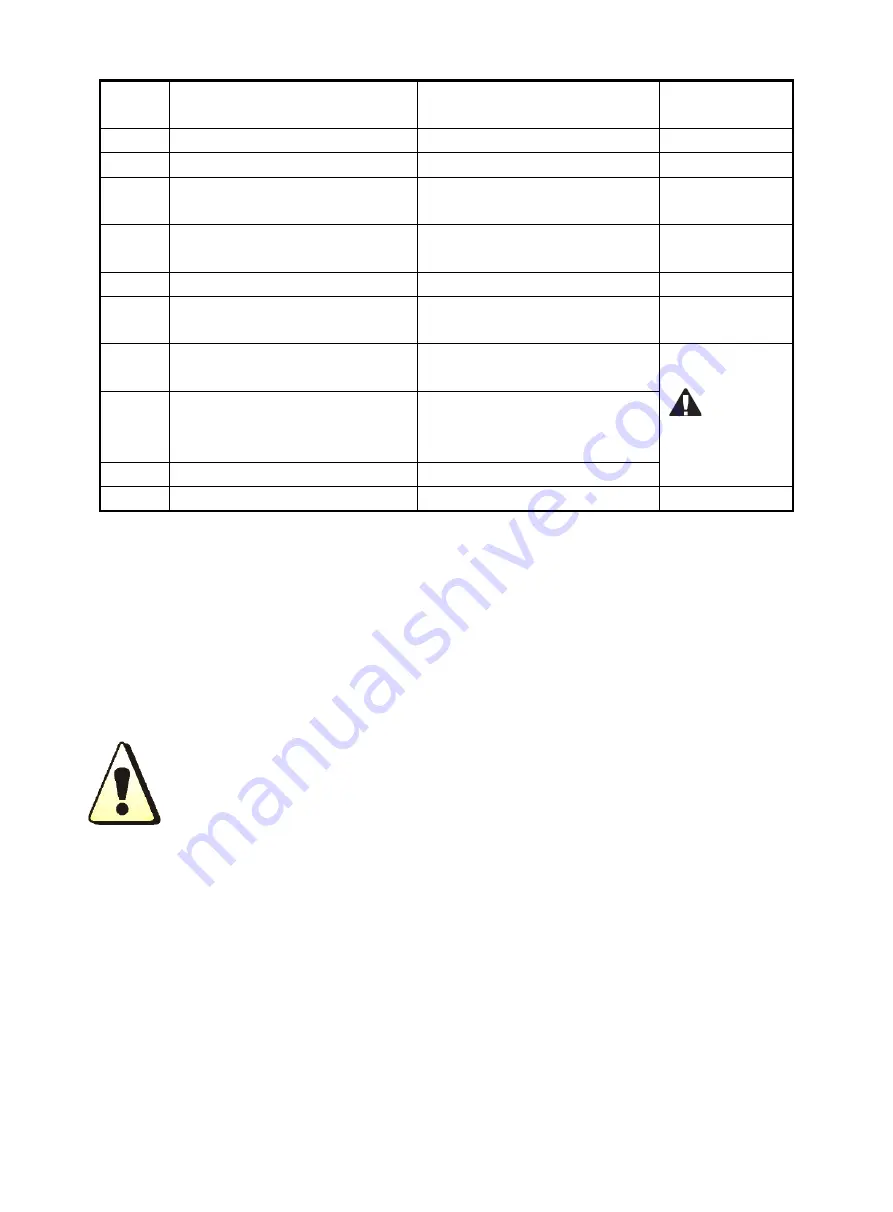

26

P5

Wire feed speed and board thickness

setting

0:speed; 1:board thickness

P6

Metric unit and English unit setting

0:metric system; 1: English system

P7

Current temperature of inverter

P8

High speed

(

22m/min

)

calibration of

wire feed speed

P9

Low speed

(

2m/min

)

calibration of

wire feed speed

P11

V.R.D switch

0:V.R.D is off

;

1:V.R.D is on

P12

Water system switch

0: water system is off; 1: water

system is on

P15

Welder overheating protection point

setting

Protective

temperature

setting

around IGBT

Please do

not change!

P22

Speed adjustment

It is defaulted as 1.00, which can be

adjusted to 0.50~1.50 times of

current speed.

P24

Slow wire feeding adjustment

0~10.0

,

plus slow feeding speed.

P23

Factory reset

0: unchanged; 1: factory reset

Note

:

Unprofessional personnel cannot adjust the internal parameters unless there is professional guidance.

6. OPERATION PRECAUTIONS

6.1 Precautions

Warning!

Crash down may cause equipment damage or personal injury. Refer to

transporting and placing methods marked on the external packing of equipment,

handle the equipment with trolley or similar handling equipment which has adequate

carrying capacity.

1) Machine lifting: use fork lift truck or crane for machine lifting. This machine has no hanging rings; please pay

attention to the fixture when lift the machine with crane.

2) input cable specs

:

To connect distribution box and machine, the cable has to be 4×6 mm

2

for MIG500 and 4×4

mm

2

for MIG350/400. The breaker or fuse in distribution box has to be bigger than 60A for MIG500 and 40A for

MIG350/400.

3) Grounding: please connect machine input cables yellow-green wire to PGND.

4) Cooling type: air cooling. Please make sure machine is well ventilated and there is nothing on the way of inlet

and outlet.

5) IP class

:

IP23

。

6) duty circle

:

Machine will stop welding output when under over-heat protection.

7) Power source inclination angle: less than 15°or machine can easily topple over.

8) Working environment: should meet the following requirements:

a) temperature : During welding -10℃

~

+40℃

,

Summary of Contents for MIG 350P

Page 13: ...11 4 6 2 Separated machine installation Figure 4 3 ...

Page 19: ...17 3 Operation modes Table 5 2 DC MIG operation modes Modes Sketch map 2T 4T ...

Page 20: ...18 Repeat Spot weldin g 5 2 3 Pulse MIG 1 Synergic and Separate ...

Page 22: ...20 2T with initial crater 4T ...

Page 23: ...21 4T with initial segmen t Special 4T pro gram 4T ...

Page 40: ...38 7 Wiring Diagram ...

Page 42: ...40 ...