31

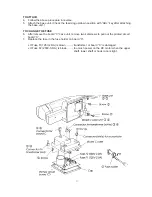

DIAGNOSIS CHART

CHECK OPERATION

If nothing happens when you turn on The power

switch, turn off The power and wait 4-5 minute.

Then turn on switch.

STEPS

01) BUZZER, LED

TEST

02) KEY TEST

03) TOUCH PANEL

TEST

04) BOBBIN

WINDER

SWITCH TEST

05) FEED DOG UP/

DOWN SWITCH

KEY TEST

06) SPEED

SETTING SLIDE

SWITCH TEST

07) FOOT

CONTROLLER

TEST

08) PRESSER

FOOT SENSOR

TEST

09) BUTTONHOLE

SENSOR TEST

10) THE AMOUNT

OF BOBBIN

THREAD

ENSOR TEST

11) UPPER SHAFT

POSITIONING

SENSOR TEST

12) STEPPING

MOTORTEST

13) MACHINE

MOTOR TEST

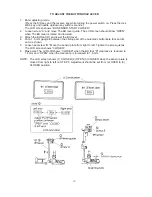

TESTING OPERATION

Turn on the power switch

while pressing

“REVERSE” key

Push START/STOP key

•

“REVERSE” key

•

“AUTO-LOCK” key

•

NEEDLE “UP/DOWN” key

•

Press

“PRESS

THIS KEY”

on left side

Press

“PRESS

THIS KEY”

on right side

•

Shift the bobbin winder

spindle to LEFT & RIGHT

position

•

Shift the drop lever to LEFT

RIGHT position

•

Move the slide switch from

left to right

•

Move the slide switch from

right to left.

•

Press the foot controller

fully and release it

•

Lower the presser bar lifter

•

Raise the presser bar lifter

•

Shift the BH lever back &

forth gently

•

Press “START/STOP” key

•

Turn the hand wheel toward

you to move the

needle bar to highest position

and lowest position

•

Raise the needle bar to

highest position and push

“START/STOP” key

•

Lower the needle bar to

lowest position and push

“START/STOP” key

•

Turn the hand wheel and

check the feed dog position

•

Press START/STOP key

CORRECT CONDITION

•

Buzzer sounds (LCD shows buzzer &

LED)

•

Red & green lights flash alternately

on START/STOP key

LCD shows “PRESS S/S, REV, AL, U/D”

•

Buzzer sounds for next step.

•

Buzzer sounds and indicates

“PRESS THIS KEY” at right hand

side on LCD board

•

Buzzer sounds for next step

LCD shows “SPOOL”

•

Buzzer sounds every time when

bobbin winder spindle is shifted

LCD shows “FEED DOG”

•

Buzzer sounds when drop lever

position is changed

LCD shows “SLIDE SWITCH”

•

Buzzer sounds at left & right

positions.

LCD shows “CONTROLLER”

•

Buzzer sounds when foot controller is

pressed fully and released

LCD shows “FOOT LEVER”

•

Buzzer sounds when foot controller is

depressed and released

LCD shows “BH SENSOR STATE”

•

When lever is pulled toward you

buzzer sounds & indicates “CLOSED”

on LCD board

•

When lever is released buzzer

sounds & indicates “OPEN” on LCD

board

LCD shows “SENSOR & SOLENOID”

•

Buzzer sounds and LCD shows “14”

without bobbin

LCD shows “PH SENSOR”

•

LCD shows “BIGHP when needle is

at highest position

•

LCD shows “FEED” when needle is at

lowest position

LCD shows “STEPPING MOTOR”

•

Stepping motor (zigzag) get default

position

•

Feeding, tension motors get default

position

•

Feed dog goes to home position

LCD shows “DC MOTOR”

•

Machine runs slow, and fast, then

needle bar stops at the highest

position

•

No buzzer sounds and could not

enter test mode

•

LED module shows program

version. Also, program will be

locked

•

LED lights or no lights on board

•

No buzzer sounds and program

will be locked

•

No buzzer sounds and program

will be locked

•

No buzzer sound

•

No buzzer sound

•

No buzzer sound

•

No buzzer sound

•

No buzzer sound

•

No buzzer sound

•

LCD shows “0”

If LCD shows No.1 - 13, adjust The

machine

•

LCD does not show “BIGHT” or

“FEED” Also LCD does not

change indication vC’hile turning

hand wheel

•

Not working correctly

•

Not stopping at the highest

position or running at uneven

speed

•

Replace board F

•

Replace board A

•

Replace board F

•

Replace board A

•

Replace touch

panel

•

Replace board A

•

Replace board A

•

Replace feed dog

switch

•

Replace board A

•

Replace slide

switch

•

Replace board A

•

Replace foot

controller

•

Replace board A

•

Replace presser

foot sensor

•

Replace board F

•

Replace board A

•

Replace BH

sensor

•

Replace board F

•

Replace board A

•

Adjust bobbin

thread sensor unit

•

Replace bobbin

Thread sensor

•

Replace solenoid

•

Replace “A”

board

* Replace upper

shaft positioning

sensor

•

Replace “A”

board

•

Replace stepping

motor

•

Replace tension

sensor

•

Replace “A”

board

•

Replace DC

motor

•

Replace “A”

board

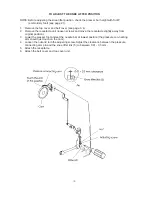

DEFECTIVE CONDITION & CORRECTION

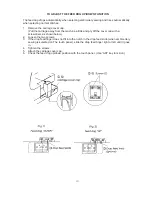

Press

appointed

key

This

key

Summary of Contents for MEMORY CRAFT 9000

Page 1: ...1 SERVICING MANUAL...