24

To prolong the life of your NitroGro applicator, perform the following on a regular basis:

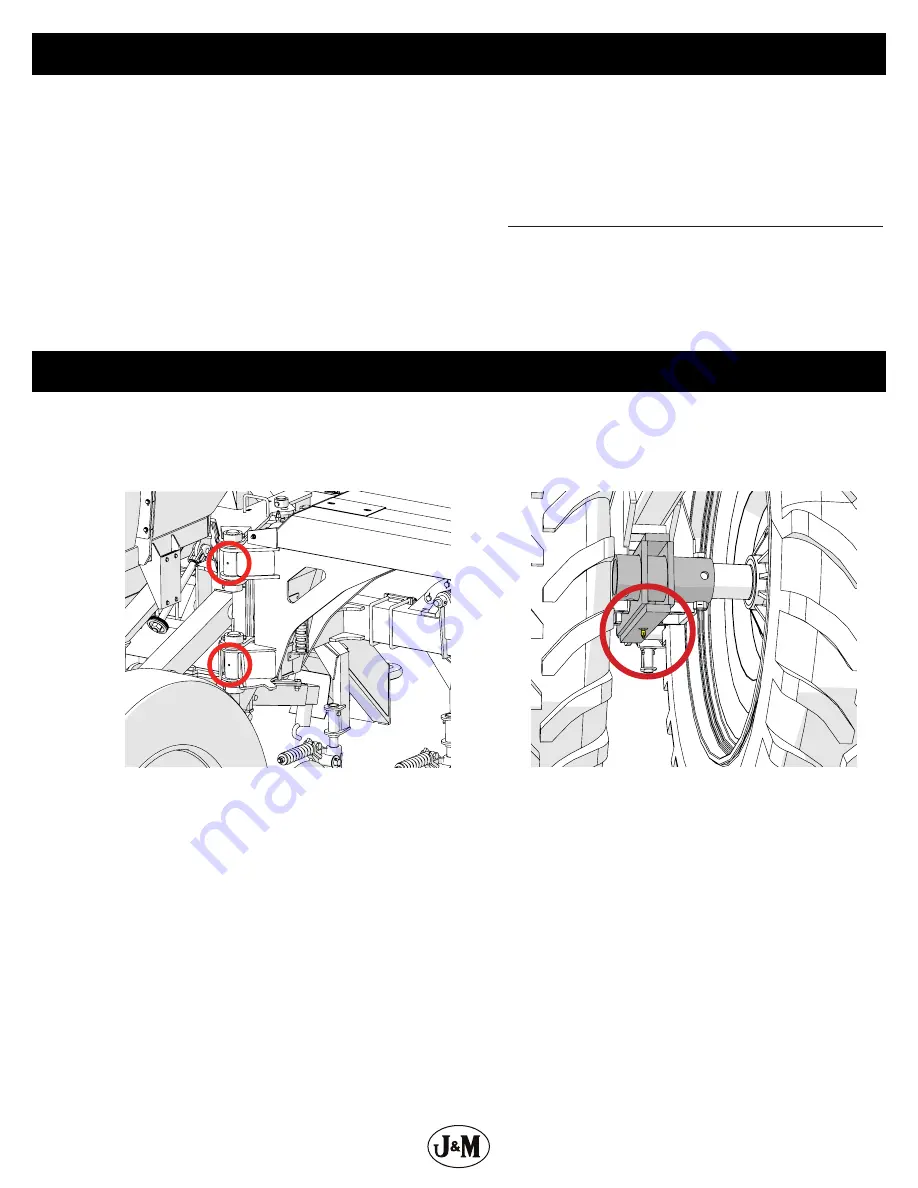

1. Grease coulter hubs with two pumps every 50 hours.

2. Grease main wing fold pivots and walker pivots every 50 hours as shown in the picture below. There are two grease points on each

side of the main wing fold (4 total). If duals are equipped, there are 1 on each side of the unit for the walking pivots.

3. Check lighting before over the road transport. Make sure lights and SMV emblem are clean from dirt and field debris.

4. Check implement for damage, cracked welds, loosened hardware, etc. After the unit is repaired promptly repaint to prevent further

damage.

5. Check hydraulic system for leaks and hose damage, twists or kinks and repair as needed.

6. Check fertilizer handling system for leaks and hose damage, twists or kinks and repair as needed.

7. Check tire pressures and lug nuts periodically and adjust as required.

8. Grease wheel hubs.

9. Grease jack every 50 hours.

10. Clean strainer daily.

11. Repack bearings for both the gauge wheel hubs and main wheel hubs each season.

12. Grease the main lift cylinder pins (4 total).

•

Comply with ALL state and local laws governing highway safety and regulations when moving machinery on public roads.

•

Be sure an SMV (Slow Moving Vehicle) emblem is in place and clearly visible on the rear of the applicator. Position the SMV emblem

with one point of the triangle upward and as near to the rear and centered or as near to the left of center of the unit as practicable.

Secure the SMV emblem two to ten feet above the ground measured from the lower edge of the emblem. Before transporting,

ensure that all lights, reflectors, and the SMV emblem are clean and visible. Ensure the amber, red, and orange reflective tape on the

implement is in place and clearly visible. Before transporting, ensure all lights, reflectors, and the SMV emblem are clean and visible.

•

When transporting applicator, do not exceed 10 MPH in the field or over rough terrain. For highway transportation, do not exceed 20

MPH. Reduce transport speed when necessary to maintain full control.

Never transport the applicator with contents in the tank.

•

Tongue weight when NitroGro is folded and empty for road transport is 600-1,000 lbs depending on the configuration. Negative

tongue weight (even intermittent) may cause instability when transporting. Add ballast to tractor as required. Never tow this

implement with a motor vehicle. Tow only with a properly ballasted tractor.

•

Be aware of overhead wires when transporting.

•

Ensure the safety chain has a rating greater than the empty weight of the machine.

•

Ensure wings are seated in the transport saddles before transporting.

Transporting

Service

Summary of Contents for 6018

Page 2: ...2...

Page 12: ...12 NitroGro Components...