ProPuls 320C

Operating manual

Page 57

21. Maintenance, coolant JPP and safety check

Disconnect mains prior to any service and maintenance work!

The welding unit is, on principle, maintenance-free. However, make it a rule to carry out the following work:

Clean current contact tip and gas nozzle regularly, removing welding spatter and other impurities. Add Anti-Stick

agent on nozzles after cleaning to reduce undesirable spatter adhesion.

Check current contact tip regularly for wear or damage, replace in time.

Clean the welding unit by air-blasting from inside according to pollution level. In order to guarantee a permanent

good cooling effect pay attention to the cooling ribs of the water cooler: they should not be covered by dust.

- ONLY use JÄCKLE coolant JPP (Order No. 900.020.400)

- Unsuitable coolants can cause property damage and loss of warranty.

- Do not mix with water or other coolant.

- Do not weld without cooling water! Tank must always be full.

- Pump must not run dry, not even for a short time. Deaerating the pump.

- Hazardous to health – keep away from children!

MATERIAL SAFETY DATA on

www.jaeckle-sst.de

available.

- Frost-resistance up to -30°C

Attention:

This Welding unit has to be safety checked every year by JÄCKLE Company or another special qualified

electrician according to the harmonized standard

IEC 60974 – 4

Safety, maintenance and inspection of arc welding equipment in use

22. Option Potentiometer remote control and Push-pull torch

Option Potentiometer remote control:

It is possible to connect two potentiometers as remote control with this equipment.

With the potentiometer 1 the welding power, and with the potentiometer 2 the arc length can be regulated.

If the potentiometer is connected, the regulation in the control box and the up / down function in the torch is

automatically deactivated.

The cables are not connected to the 7-pin socket in the wire feeder.

If necessary, the cables must be connected to a further socket.

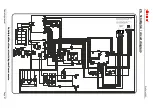

The wiring is described in chapter 26 – Circuit diagrams, page 72.

Ground

gray wire, +10 VDC

light blue wire, potentiometer 1

green wire, potentiometer 2

blue wire

ATTENTION

: As shown in the circuit diagram, there must be mandatory installed a protection diode in the

ground wire!

Option Push-Pull Torch:

ATTENTION:

it may only be connected a push-pull system for 24V DC!

42V or 48V systems are not permitted and lead to damage!

The cables are not connected to the 7-pin socket in the wire feeder.

If necessary, the cables must be connected to a further socket.

The wiring is described in chapter 26 – Circuit diagrams, page 72.

+24V DC (Push-Pull)

white wire, Ground

black wire

Summary of Contents for ProPuls 320 Compact

Page 2: ......

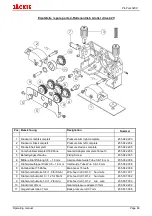

Page 66: ...ProPuls 320C Operating manual Page 62 25 Ersatzteile spare parts Frontansicht front view...

Page 68: ...ProPuls 320C Operating manual Page 64 Seitenansichten side view...

Page 73: ...ProPuls 320C Operating manual Page 69 27 Schwei programme Program table...

Page 74: ...ProPuls 320C Operating manual Page 70...

Page 75: ......