ProPuls 320C

Operating manual

Page 54

If the machine is equipped with an UP/DOWN torch, within a sequence, changes can be made between welding

points that are adjacent to one another during the welding process.

Without an UP/DOWN torch, this is not possible.

How quickly the individual points of the welding process can be changed can be regulated by using the Fx

function button and the setting jobslope (current increase between sequences).

For this, press the Fx button and change the slope with the dial.

During start-up, it is not mandatory to start with the first point in the sequence because the machine has the last

active point in its memory. In this connection, select the appropriate welding point with the program selection

button and start.

When you have come to the beginning or end of the sequence, the program always goes the corresponding

opposite end.

e.g.:

Beginning Job 5 Job 6 Job 7 JOB 8 End

Beginning Job 5 Job 6 Job 7 JOB 8 End

18.7 Welding aluminium

For welding aluminium, small adjustments have to be made to the welder so as to ensure trouble free welding

operation:

Wire feed:

use special aluminium wire feed rolls

Contact pressure: of the rolls is reduced, deformation of the wire is undesirable

Torch:

select as short as possible and equip with a Teflon core

Use argon welding gas

19. Start-up

19.1 Transport

During unpacking, ensure that the delivery is complete and check for possible transport damage.

Any shortcoming, whether it be due to an incomplete delivery or transport damage should be reported to the

haulage company, the insurance company and the company JÄCKLE or one of their dealers immediately in

writing.

19.2 Setting up the welder

When setting up the welder, pay attention to ensuring that enough clearance is available for the cooling air to

move in and out freely so that the specified duty cycle can be achieved (at least 1.5m). As far as possible, the

welder should not be exposed to moisture, welding spatter or direct fountains of sparks during grinding work.

Attention:

Metallic deposits inside the unit can lead to short circuits and therefore to irreparable damage of the welder.

(metal dust in the air)

The welder should not be used outdoors in the case of rain.

Connect mains plug

(if required)

The mains plug must only be connected by a qualified electrical technician according to the specifications on

the rating plate.

Connecting the shielding gas cylinder

Place the shielding gas cylinder on the back of the transport vehicle and secure it with chains. Connect the

cylinder pressure reducer and check the connections for leaks.

Connect the welding torch-hose assembly

Summary of Contents for ProPuls 320 Compact

Page 2: ......

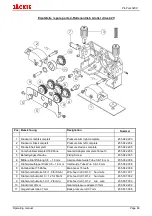

Page 66: ...ProPuls 320C Operating manual Page 62 25 Ersatzteile spare parts Frontansicht front view...

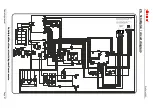

Page 68: ...ProPuls 320C Operating manual Page 64 Seitenansichten side view...

Page 73: ...ProPuls 320C Operating manual Page 69 27 Schwei programme Program table...

Page 74: ...ProPuls 320C Operating manual Page 70...

Page 75: ......