Jabiru Aircraft

Pty Ltd

Installation Manual

Jabiru 3300 Aircraft Engine

REVISION

0

1

2

3

4

5

6

7

Dated : 1

st

Dec 2016

Page: 30 of 56

The Bing altitude compensating carburettor uses bowl float level and two main air circuits

– the idle and the

needle/main

– to control the mixture. Both circuits use jets to meter the rate at which fuel is allowed to flow.

The jets are small brass parts with precisely controlled openings (both the size of the opening and the shape

surrounding the opening affect fuel flow rate) which can be changed to adjust engine mixture.

The main and idle jets have simple fixed apertures, while the effective size of the needle jet aperture varies,

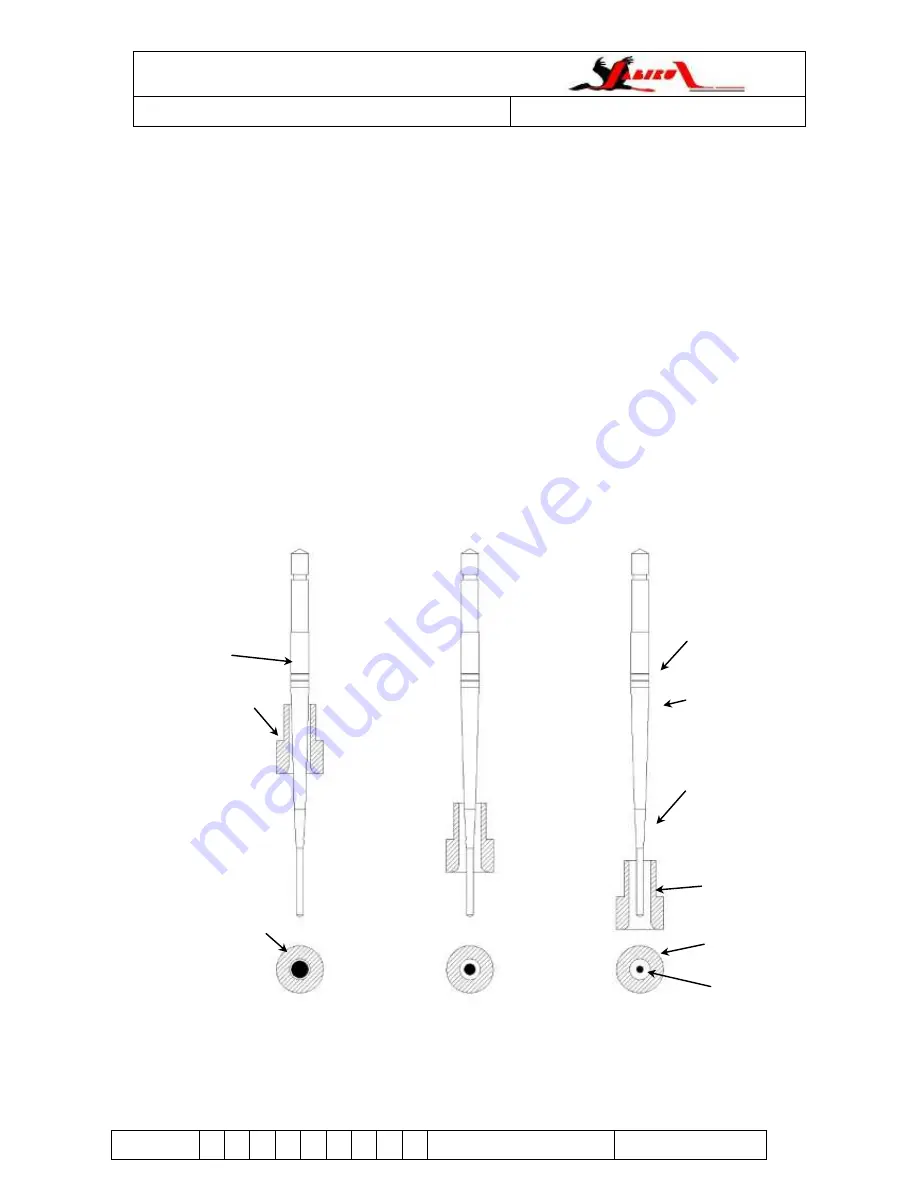

depending on the diameter of the needle. Figure 32 below shows three different throttle settings in the

needle jet and the corresponding difference in aperture. On the left is a low power setting, where the needle

jet is nearly completely blocked by the needle. The middle throttle setting corresponds approximately to a

high cruise power setting. The gap between the needle and the sides of the jet is much larger. The final

setting corresponds approximately to wide open throttle. The needle jet is now effectively not there, and the

amount of fuel flowing is controlled by the main jet (located upstream of the needle jet in this circuit).

The shape of the taper of the needle controls the mixture at a given throttle setting. The needle used in

Jabiru engines been optimized for use with a propeller, which puts a very non-linear load on the engine; to

double the RPM of a propeller a lot more than double the power has to be applied.

To achieve a good mixture with the type of load applied by a propeller, the Jabiru needle uses two-stage

taper and a straight tip. The more gradual taper at the upper end of the needle gives a leaner mixture in low-

power cruise settings and at lower RPM where the propeller is using relatively little power. The sharper

taper at the lower end ramps up rapidly to a much richer mixture at higher power settings. The straight tip of

the needle is used when the throttle is wide open and the engine’s mixture is being controlled by the main

jet. This rich mixture at full power protects the engine from detonation.

The transition from lean, cruise mixtures to richer full-power mixture will occur at around 2800

– 3000 rpm

on 4 and 6 cylinder engines, when fitted with an appropriate propeller. For most efficient operation, the

transition must be above cruise rpm. The transition can clearly be seen by changes in the EGT.

Figure 32. Needle Jet (Jabiru Needle)

Because of the way the carburettor uses the sense ports and balance tube to regulate the mixture it is

sensitive to the way the intake air moves, and to the conditions of the intake system.

Section 6 below contains information on setting up the induction system.

Needle Jet (cross

section view)

Jabiru Needle

View looking through

needle jet

Needle Jet

Needle

Slow, linear taper for

cruise power & below.

Steeper linear taper for

transition between lean

cruise mixture and rich,

high power mixture.

Parallel end for full

power

Jabiru 3300 needle shown,

with 3 shallow grooves

machined above taper.