Configuration

3.2 Pin

assignment

3.2.1 CAN

bus

connection

One (common) or two independent bus connectors according to ISO/IS 11898-2

can be installed on iPC-I 165/PCI.

The signals of the 1st bus interface are provided by the 9 pole sub-D plug/sleeve.

If two independent bus interfaces are installed the signals for the CAN bus of the

2nd bus interface are provided by the connector JP19. Both of the CAN interfaces

can be optionally galvanic decoupled from the CAN bus.

As another option a version without any bus interface on the board is available.

In this case the signals are provided by separate connectors (X8/X9 for the 1st

CAN, X10/X11 for the 2nd CAN circuit).

The 1st CAN circuit is connected to the 9 pole pin/sleeve X4/X5 via the plug con-

nectors X8 and X9. If both CAN lines are installed and connected together then

they will be connected via these plug connectors, too.

The 2nd CAN circuit is connected to the connector JP19 via the plug connectors

X10 and X11. If the bus interface according to ISO/IS 11898-2 is already installed

on-board the plug connectors X8/X9 and X10/X11 are not present.

The signals of the CAN controllers 1 and 2 and four portpins of the microcontrol-

ler are available at X8 / X10.

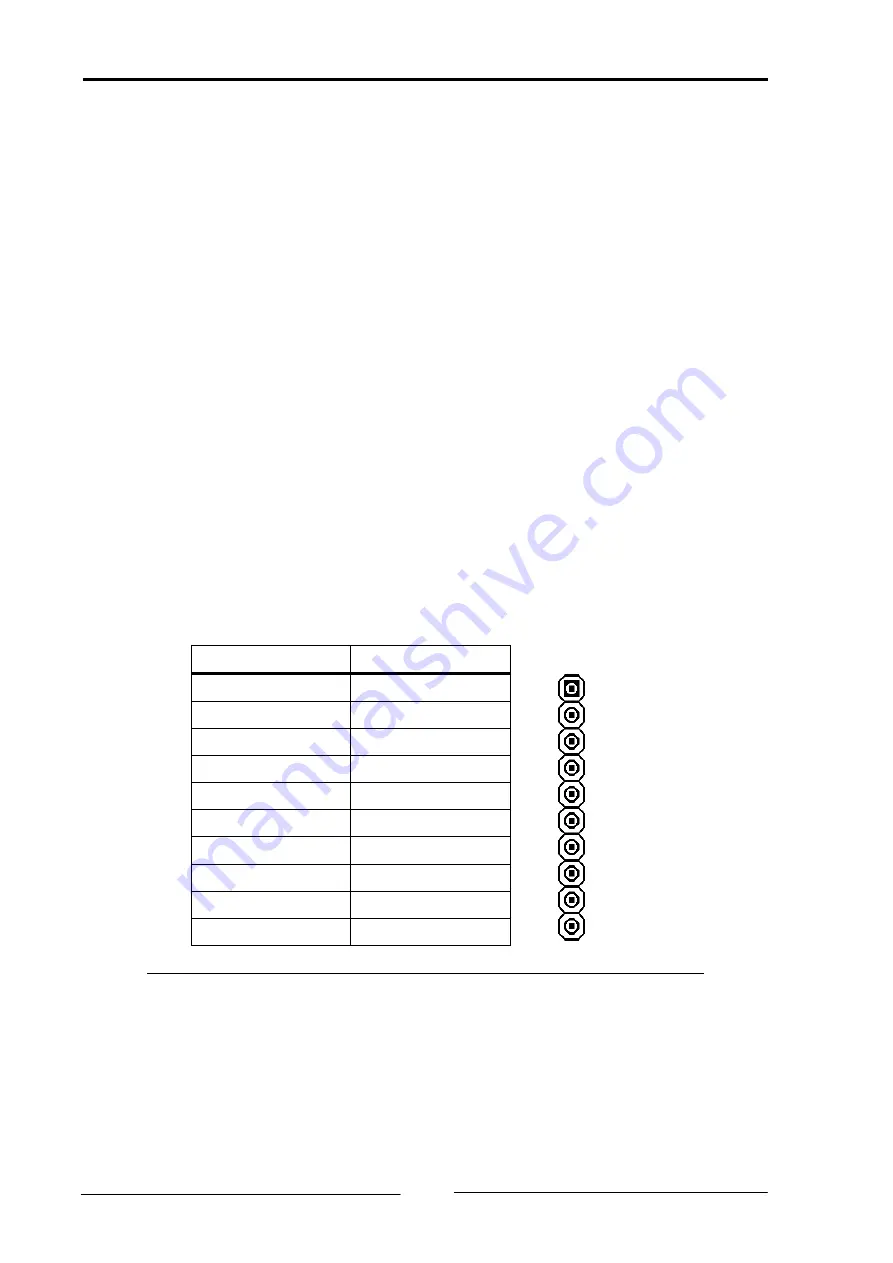

Pin No. X8/X10

Signal

1 VCC

2 GND

3 Port

3.10*

4 RX0

5 RX1

6 TX1

7 TX0

8 Port

5.2

9 Port

3.11*

10 Port

5.3

Tab. 3-3: Pin assignment X8/X10

* If a serial interface is assembled, the port pins 3.10 and 3.11 must not be used

by a piggyback board!

Copyright IXXAT Automation GmbH

iPC-I 165/PCI - Manual, Version 2.3

10

Summary of Contents for iPC-I 165/PCI

Page 4: ......