4.5.3 Suction-piping checklist

Performance curve reference

Net positive suction head available (NPSH

A

) must always exceed NPSH required (NPSH

R

) as shown on

the published performance curve of the pump.

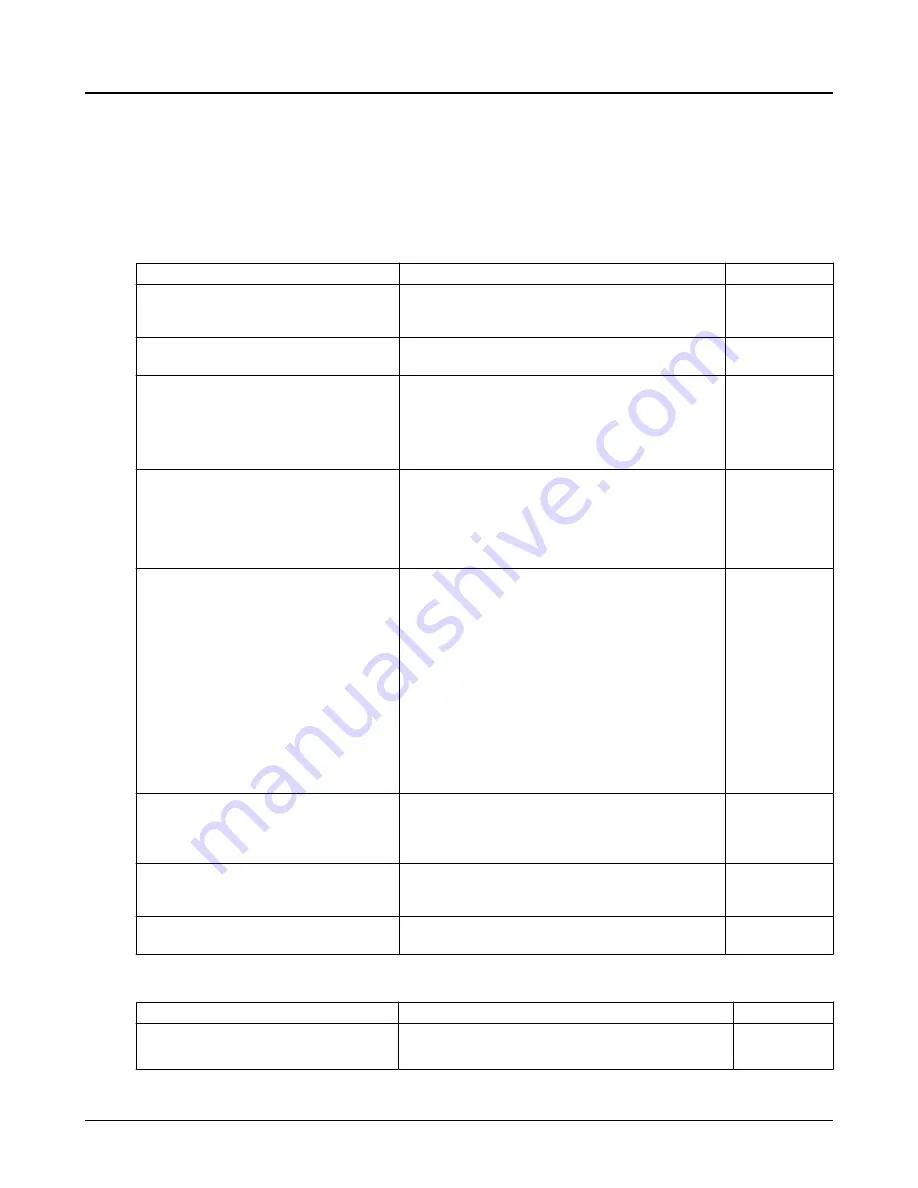

Suction-piping checks

Check

Explanation/comment

Checked

Check that the distance between the inlet

flange of the pump and the closest elbow

is at least two pipe diameters.

This minimizes the risk of cavitation in the suction in-

let of the pump due to turbulence.

Check that elbows in general do not have

sharp bends.

—

Check that the suction piping is one or two

sizes larger than the suction inlet of the

pump.

Install an eccentric reducer between the

pump inlet and the suction piping.

The suction piping must never have a smaller diame-

ter than the suction inlet of the pump.

Check that the eccentric reducer at the

suction flange of the pump has the follow-

ing properties:

•

Sloping side down

•

Horizontal side at the top

Suggested suction strainers are used.

Check that they are at least three times the

area of the suction piping.

Monitor the pressure drop across the suc-

tion strainer.

An increased pressure drop across the

strainer of 34.5 kPa | 5 psi indicates that

the strainer should be removed and

cleaned.

After a period of time (24 hours minimum)

system flushing should be complete and

the suction strainer can be removed.

Suction strainers help to prevent debris from entering

the pump.

Mesh holes with a minimum diameter of 1.6 mm |

1/16 in. are recommended.

Liquids with specific gravity less than 0.60 a pressure

drop across the suction strainer may be due to ice

buildup. Ice buildup can cause turbulence, low pres-

sure areas and pumpage vaporization.

If more than one pump operates from the

same liquid source, check that separate

suction-piping lines are used for each

pump.

This recommendation helps you to achieve a higher

pump performance and prevent vapor locking espe-

cially with specific gravity of liquid less than 0.60.

If necessary, make sure that the suction

piping includes a drain valve and that it is

correctly installed.

—

Assure adequate insulation is applied for

liquids with specific gravity less than 0.60.

To assure sufficient NPSHa.

Liquid source below the pump

Check

Explanation/comment

Checked

Make sure that the suction piping is free

from air pockets.

This helps to prevent the occurrence of air and cavita-

tion in the pump inlet.

4.5 Piping checklists

Model 3355 Installation, Operation, and Maintenance Manual

33