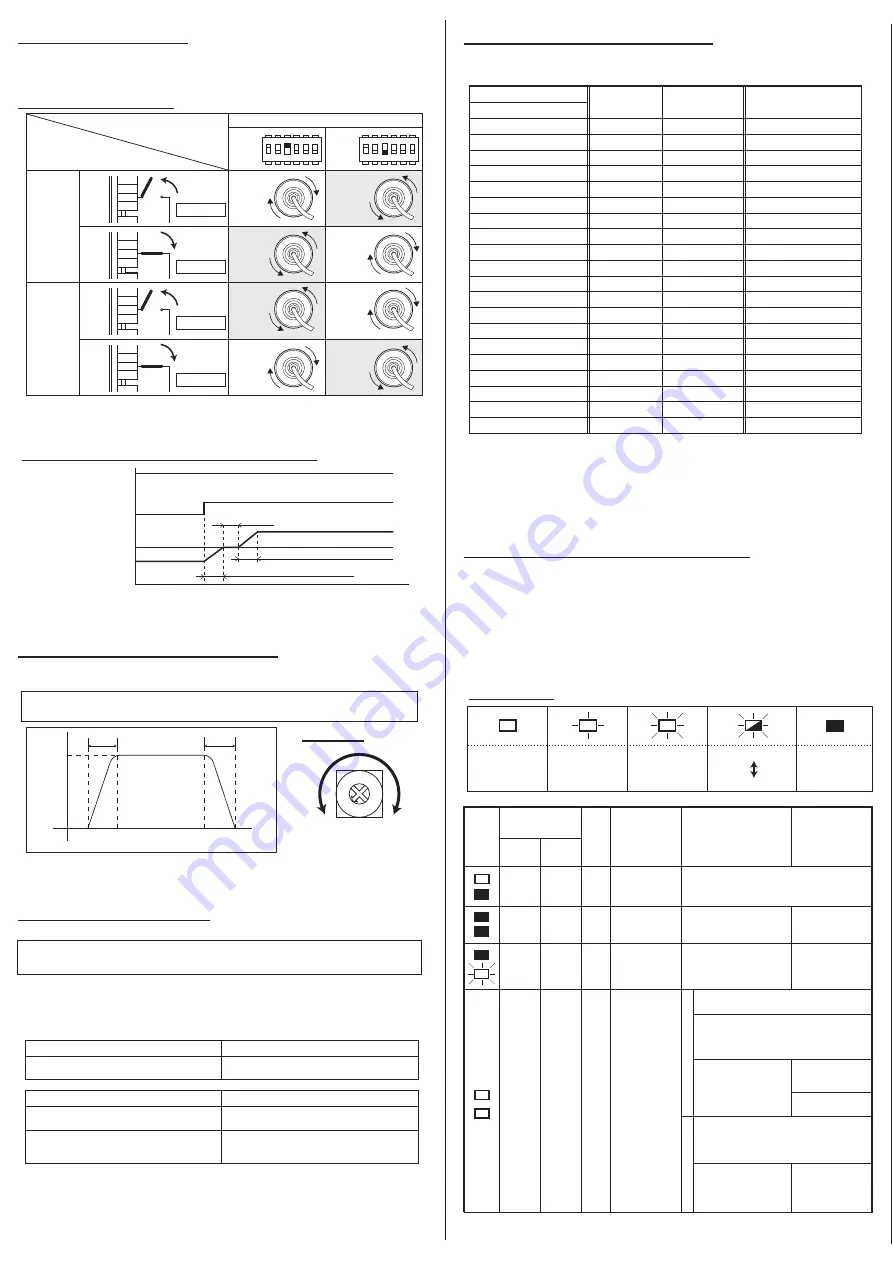

5-2. Direction Setting

8. Error status, Reset and History

5-3. Acceleration and Deceleration

Reverse direction by external DIR signal can be permitted even while motor is running.

Power Moller turning direction can be set or changed either internally by integral DIP

switch or externally by optional switch.

・

Discharged the error signal discharged when power is injected to the driver card

(for 0.5sec) and when power to the driver card is shut off(for 2 seconds)

Error signal is discharged from CN2-4.

6. Error Signal Output

・

Power Moller’s motor pulse signal is discharged from CN2-5.

・

2pulses/motor rotation, NPN open collector output.

・

When error arises, the error can be identified either by LED1(Green) and LED2(Red)

or by the error signal discharged from CN2-4.

・

To reset the error status, first remove the cause of error, and then switch the direction

signal at CN2-2.

・

To restart to Power Moller, first remove the cause of error, and then re-inject RUN

signal at CN2-1.

7. Motor Pulse Signal Output

SW1-4 allows the selection of the error signal discharge timing: discharge on normal

status or discharge when error arise. Error signal is PNP open collector in case of

CBM-105FP.

※

See section 8 for error status, reset and history.

①

※

Protective resistor should be mounted to suppress the output to be 25mA or less,

otherwise the driver card’s integral transistor may e damaged.

※

100

Ω

protective resistor is built-in the driver card output section for error output.

※

Protective resistor should be mounted to suppress the output to be 25mA or less,

otherwise the driver card’s integral transistor may e damaged.

※

100

Ω

protective resistor is built-in the driver card output section for motor pulse

output.

Integral potentiometer VR1 allows the acceleration adjustment from 0 to 2.5seconds.

Integral potentiometer VR2 allows the deceleration adjustment from 0 to 2.5seconds.

①

②

※

Turning direction viewed from the Power Moller’s power cable side.

※

0V should be common to power voltage.

※

7.3mA current is drawn at CN2-2.

※

Reverse direction by DIP switch is prohibited while motor is running. Motor must be

stopped first, and then reverse a direction by DIP switch.

VR(1)

VR(2)

SW1-4 OFF

SW1-4 ON

SW1-6 ON

SW1-6 OFF

Error signal discharges in normal status

Error signal discharges when error arises

PNP open collector output

NPN open collector

Open on normal

Transistor on PCB is ON when error arises

Open on error

Transistor on PCB is OFF when error arises

(

7

)

(

6

)

(

)

(

)

FE

type

FS/FP

type

ON

S W 1 - 3

OFF

・

The adjustable range of time is on the control basis, thus may differs on actual

transfer speed.

Setting for Turning Direction

CW/CCW

Reverse motor direction by external DIR signal. (CN2-2)

CW

CCW

CW

CCW

CCW

CW

CCW

CW

Disconnected

CW/CCW

Connected

Disconnected

Connected

CW/CCW

CW/CCW

VR1

・

VR2

Internal speed variation

SW2

Frequency

(

Hz

)

Motor speed

(

r/min

)

Analog voltage input

(V)

9

166

4969

9.6~9.9

8

152

4556

9.1~9.4

-

145

4349

8.6~8.9

7

138

4141

8.1~8.4

-

131

3934

7.6~7.9

6

124

3727

7.1~7.4

5

110

3313

6.6~6.9

-

104

3106

6.1~6.4

-

97

2899

5.6~5.9

-

90

2692

5.1~5.4

4

83

2485

4.6~4.9

-

76

2278

4.1~4.4

-

69

2071

3.6~3.9

-

62

1864

3.1~3.4

3

55

1657

2.6~2.9

-

48

1450

2.1~2.4

2

41

1242

1.6~1.9

-

35

1035

1.1~1.4

1

28

828

0.6~0.9

0

21

621

0.1~0.4

※

Reset the error by CN2-1(Run signal), the Power Moller start running immediately.

※

In case power is 8.5V or less, the driver card may not work properly.

Speed deviation

:

±3

%

R U N

S TO P

O N

O F F

CN2-2

Reverse

Normal

Deceleration setting time(VR2)

Turning direction

Acceleration setting time(VR1)

0 . 5 S

1

2

3

4

5

6

1

2

3

4

5

6

ERR

V-IN

RUN

DIR

1234

ERR

V-IN

RUN

DIR

1234

ERR

V-IN

RUN

DIR

1234

ERR

V-IN

RUN

DIR

1234

LED indication

Set

Speed

0sec

(Min)

2.5sec

(Max)

Illuminates

Blinks at 1Hz

Blinks at 6Hz

Blink twice at 6Hz

Off for 1.5sec

Off

LED1

(Green)

LED2

(Red)

CN2-4

(

Error signal

)

SW1-4

ON

SW1-4

OFF

Symptom/

Causes

Reset the error signal

Restart the

Power Moller

MDR

Open

Open

Open

Discharge

Discharge

n.a.

n.a.

STOP

Open

STOP

Discharge

Open

STOP

Normal operation

No power

Supply 24VDC power

See section 5

See section 5

PCB damaged

Shut off the power then

replace the driver card

Thermister reacted

(Thermister error)

Automatic recovery setting

Manual recovery setting

Power Moller restart immediately 1 minute

after Thermister recovery from cooling off.

Power Moller restarts by injecting RUN signal

followed by STOP signal to CN2-1 to reset the

error signal then inject RUN signal to CN2-1 to

restart, 1minute after Thermister recovery.

After Thermister recovery,

inject signal ON-OFF-ON

or OFF-ON-OFF order to

CN2-2

Inject signal RUN-

STOP-RUN order to

CN2-1

Restarts automatically

in a minute.

Power Moller restarts by injecting RUN signal

followed by STOP signal to CN2-1 to reset the

error signal then inject RUN signal to CN2-1 to

restart, 1minute after Thermister recovery.

After Thermister recovery,

inject signal ON-OFF-ON

or OFF-ON-OFF order to

CN2-2

Inject signal RUN-

STOP-RUN order to

CN2-1