3-3. Direction Setting

5-1. Speed Variation

5. Operation Instructions

・

Power Moller is adequately installed in compliance with the manual.

・

Power Moller shafts are adequately secured with the supplied brackets or

accessories.

・

Each connector on the driver card is adequately wired and inserted.

・

Operating and environmental conditions are respected.

・

Power supply has sufficient capacity (Stable 24VDC, 5A or over) so as not to be

affected by varying load

・

The protector for the power supply should not react with peak current 20A

1msec or less.

Supply 24VDC to the driver card, and the LED1(Green)

illuminates.

Close the contact of CN2-1, and the Power Moller starts

running.

・

0V should be common to the power voltage.

・

7.3mA current is drawn to CN2-1.

・

Wait 1sec after the driver card is powered before

running Power Moller.

Open the contact of CN2-1, and the Power Moller stops.

・

Power Moller run/stop should be manipulated only

by CN2-1 and 0V, not by the 24VDC power to the

driver card.

To vary the motor speed, follow the section 5-1.

To reverse the motor, follow the section 5-2.

To accelerate or decelerate the motor, follow the section 5-3.

①

②

③

④

⑤

⑥

①

Wire 24VDC and 0V to the Power Connector CN1(2P)

Connector current capacity is 10A.

Avoid

wiring causing excessive current.

Make sure the +/- wiring is correct.

Wiring should be made before inserting into the

driver card.

②

Wire to the Control Connector CN2 (5P) per the diagram in section 3.

③

Insert the pre-wired Power connector CN1, Control connector CN2 and Motor

connector respectively to the counter connectors in the diver cad.

(Motor connector to CN3) while the power is shut off.

【

5-1-1. Internal Speed Variation

】

①

Set the SW1-2 OFF to effect the internal speed variation.

②

Speed can be varied by Rotary Switch(SW2) in 10steps.

Speed of the Power Moller can be varied either internally by internal Rotary

Switch (SW2) or externally by analog voltage input(CN2).

Motor direction can be changed by SW1-3 or CN2-2.

→

See section 5-2

※

he setting differs according to the Power Moller model. Check the model from the

circular label put on the Power Moller end housing.

Example

P M 4 8 6 F E - 6 0 - 4 0 0 - D - 0 2 4

【

5-1-2. External Speed Variation

】

①

Set the SW1-2 ON to effect the external speed variation.

②

Inject and vary the analog voltage between 0V and 10V to CN2-3 to vary the motor

speed in 20steps.

※

Max 2mA current is consumed at CN2-3.

※

The analog voltage input should not exceed 10V. Its 0V should be common to

the Power Voltage.

(

2

)

(

3

)

7mm

0.5

~

1.5mm

2

DC 24V

(

AWG:20

~

14

)

(

AWG:28

~

20

)

DC 0V

7mm

0.08

~

0.5mm

2

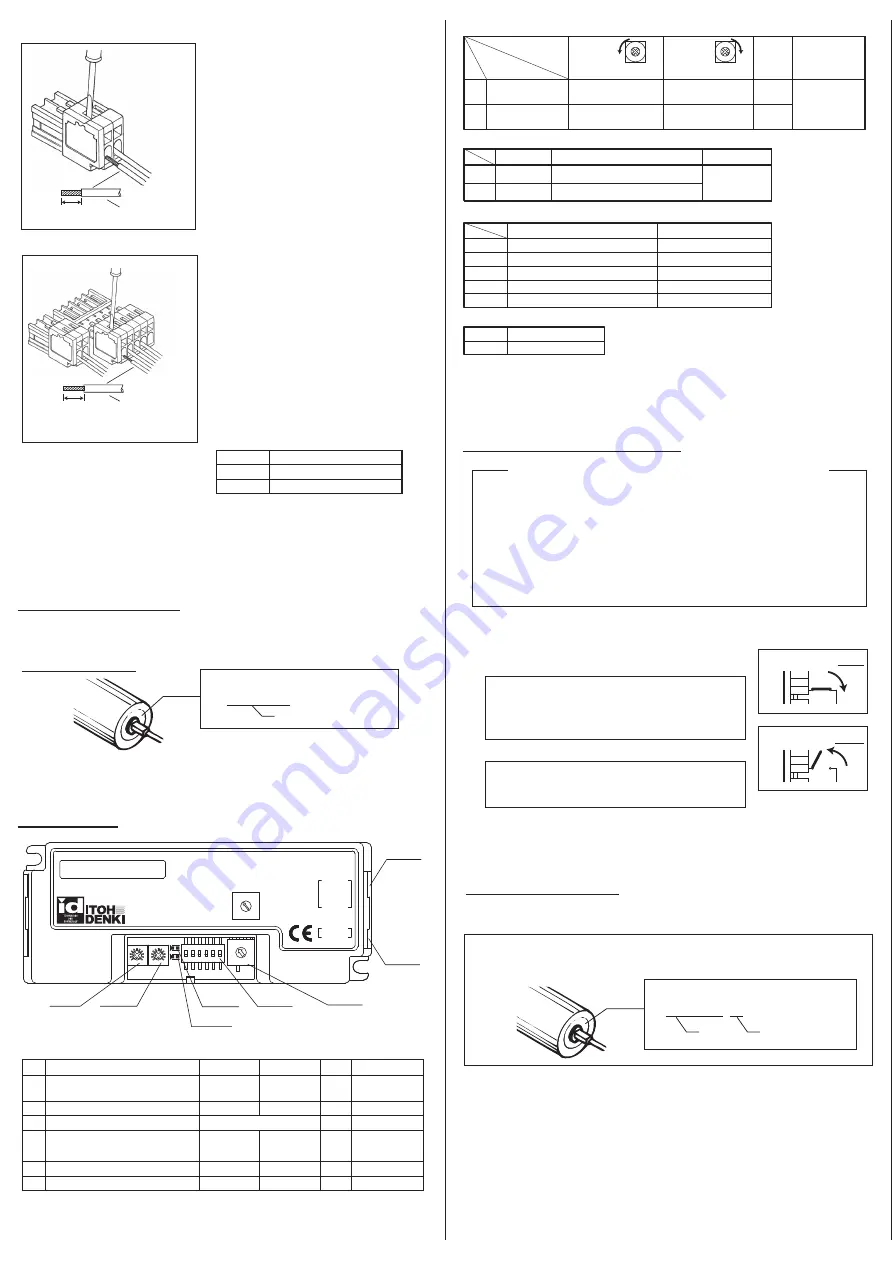

4. Function

No

Function

ON

OFF

Default

Remarks

1

2

3

4

5

Thermister / Low Voltage / Back EMF

Auto Reset / Manual Reset

Manual

Automatic

O N

See section8

See section 5-1

See section 9

See section 5-2

See section 6

O F F

Speed variation

External

Internal

O F F

O F F

O F F

Direction

See section 5-2

Error signal

Discharged in

normal status

Discharged in

error stats

Brake Type

Servo

Dynamic

6

See section 6

※

※

In case of CBM-105FN; Default setting on SW1-6 is OFF

In case of CBM-105PN; Default setting on SW1-6 is ON

Error signal output type

PNP

NPN

①

Dip Switch (SW1)

2

1

0V

DC24V

⑤

Power Connector (CN1)

⑥

SW2

10 index speed setting

(

※

20 index speed setting on external speed function

)

5

4

3

2

1

Function

See section 7

Motor pulse signal output

See section 6

Error signal output

See section 5-1

External speed variation

See section 5-2

Motor turning direction

See section 5

Motor RUN/STOP

④

Control Connector (CN2)

1

2

Powered and functions normally

Indicates type of error

Green

Remarks

Remarks

Status

Color

Red

③

LED

See section8

Ensure the following before operating the product

Model

Model

Model nomenclature

Example

PM486FE-60-400-D-024

Nominal Speed

・

Range of speed variation differs according to the Power Moller model.

Check the nominal speed of the model from the circular label put on its end

housing.

V-IN

RUN

DIR

123

RUN

V-IN

RUN

DIR

123

STOP

③

LED2

①

SW1

③

LED1

⑥

SW2

④

CN2

⑤

CN1

SW2

SW1

LED1

LED2

4

3

2

1

0

9

8

7

6

5

SPEED

6

5

4

0 1

9

8

7

2

3

24V

1.RUN

3.V-IN

2.DIR

4.ERR

5.PLS

0V

CBM-105F□

4. E/N-OUT

2. INT/EXT

3. DIRECTION

1. AUTO/MANU

ERR/PWR

5. SV

-BRK

6. N/P-OUT

VR1-ACC

VR2-DEC

VR2

VR1

4

3

2

1

DEC

ACC

CBM-105

②

VR1

②

VR2

SW1-6

ON

OFF

Error signal output

PNP Open collector

NPN Open collector

※

※

※

0V to CN2-1(Run/Stop) and CN2-2

(CW/CCW) should be common to the power

voltage.(Connector current capacity is 4A)

Analog voltage input to CN2-3(External

voltage) should not exceed 10V. 0V should

be common to the power voltage.

CN2-4(Error signal output) can be selected

by SW1-6.

Connecting with external device such as

Relay Coil requires apply coil surge

absorption type or add protective devices to

protect from surge otherwise remote

OUTPUT in CBM-105 may be damaged by

back EMF when output signal is changed.

Motor Pulse signal from CN2-5 is NPN Open

collector.

※

※

※

※

※

※

Connecting with external device such as

Relay Coil requires apply coil surge

absorption

type or add protective devices to protect

from surge otherwise remote

OUTPUT in CBM-105 may be damaged by

back EMF when output signal is changed.

Default

Remarks

See section 5-3

Min

Min

Min

1

Acceleration from

RUN signal

0 sec

2

Deceleration from

STOP signal

0 sec

2.5 sec

2.5 sec

②

Potentiometer (VR)

(

To the CCW end

)

(

To the CW end

)

Max