10.

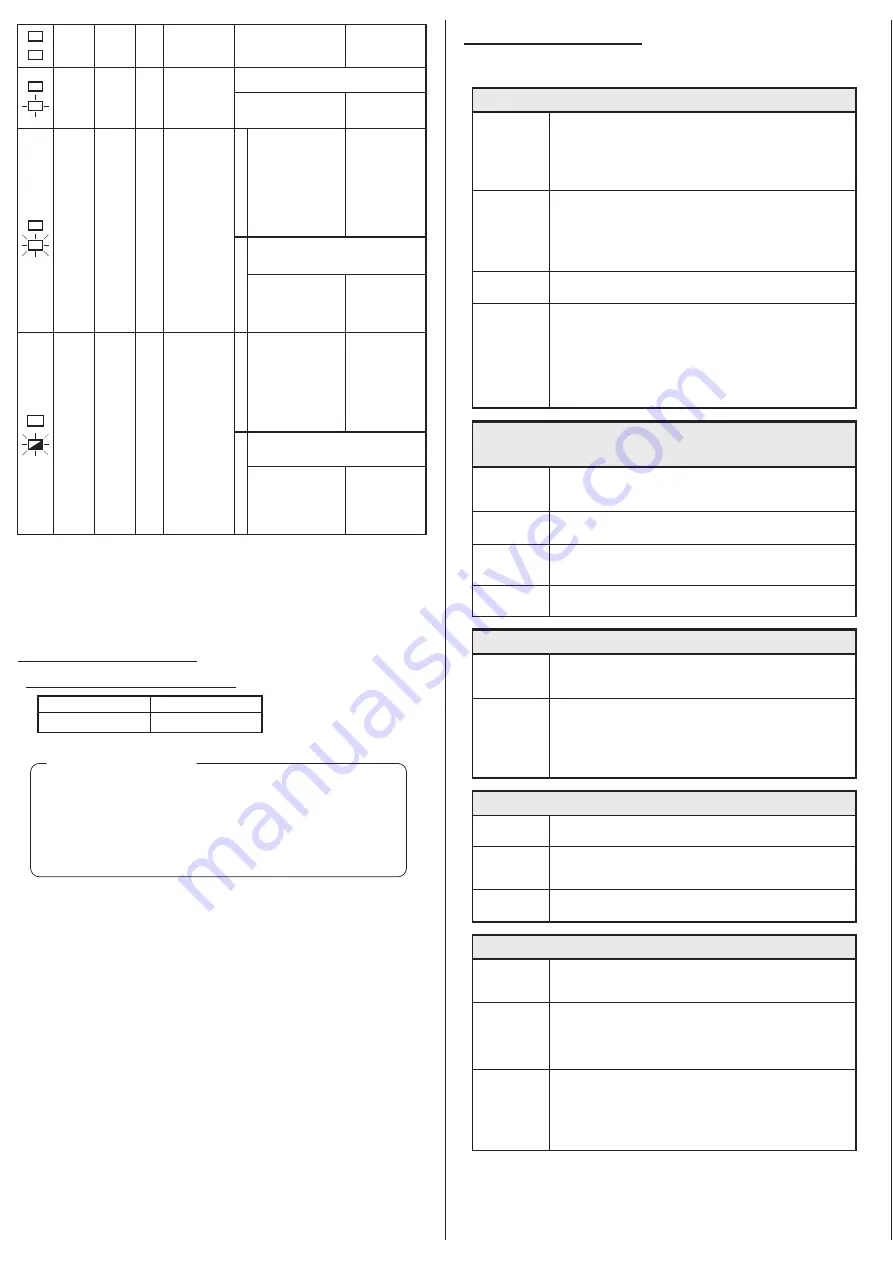

Troubleshooting

Servo Lock Brake torque and current

※

Follow the procedures below without removing plastic cover or modifying the

driver card, in case any problem happened.

9.

Servo Lock Brake

・

Hold Power Moller stop position when the Servo Lock Brake function

is working.

・

Move back to original stopped position when Power Moller force to

be moved by external force.

・

This feature is useful for conveyor where Power Moller is turned by

external force.

(Decline, Incline conveyor...etc)

Symptom 1; Power Moller does not run.

Power

RUN signal

Error

Power Moller

・

Check if only LED1 (Green) illuminates.

・

Check if 24VDC stable voltage is adequately supplied from

the power supply.

・

Check if the wiring to CN1 connector is made correctly.

・

Check if 24VDC cable is adequately wired to the CN1

connector.

・

Check if RUN signal is injected to CN2-1.

・

Check if signal is injected to CN2-1 is proper voltage.

0V for NPN setting, 24VDC for PNP setting.

・

Check if the wiring is adequately made to CN2-1 connector.

・

Check if the 0V injected to CN2-1 is common to 0V injected

to CN1-2.

・

Check if LED2 is illuminating or blinking. If this is the case,

see section 8 and remove the cause of error.

・

Check if the Power Moller is adequately installed and its

shaft are adequately fixed with the supplied mounting

brackets or accessories.

・

Check if the Power Moller end housing is NOT contacting

conveyor frame.

・

Check if the Power Moller’s connector is

properly inserted to the driver card.

・

Check if the belt tension is not too strong.

・

Check if the number of slaved idler rollers are adequate.

Symptom 2; Speed variation is not achieved, or speed is slower

than expected.

Power Moller

SW

1

-2

setting

Power

CN2-3

・

Check if the nominal speed of the Power Moller to se if the

right model is used to achieve the speed variation or to

reach expected speed.

・

Check if the SW1-2 is set properly: ON for external speed

variation and OFF for internal speed variation.

・

In case of external speed variation, check if the 0V is

common to the 0V input to CN1-2.

・

Check if the stable 24VDC is supplied.

・

Check if the wiring is adequately mode to CN2-3 connector.

・

Check if the analog voltage input is made between 0 and 10V

Symptom 4; Error Signal Not Discharged.

SW

1

-4

Voltage

CN2-4

・

Check if the setting is made properly for discharge on

normal or discharge when error arises.

・

Check if the external voltage is 24VDC or less and its 0V is

common to the 0V input to CN1-2.

・

Check if the load(resistor) larger than 1k

Ω

is mounted.

・

Check if the wiring is adequately done to CN2-4.

(

Wired for NPN or PNP)

Symptom 5; Error signal is often discharged.

LED 2(Red)

Environment

Power Moller

・

Check if LED 2 (Red) is blinking. If this is the case, thermal,

lock, low voltage or Back EFM error is arises. See section 8

・

Check if power supply is enough capacity. See section 2

・

Check if the product is used in the ambient temperature

range between 0 and 40

℃

.

・

Check if the driver card back plate is affixed to the metallic

plate face for better heat dissipation.

・

Check if the Power Moller is stalled in the conveyor line.

・

Check if the Power Moller end housing is contacting the

conveyor frame.

・

Check if the Power Moller’s connector is properly inserted to

the driver card.

・

Check if the Roller cable is disconnected, or about to

disconnect.

Symptom 3; Reversing is not achieved.

CW/CCW

SW

1

-3

・

Check if 0V is injected to CN2-2, and it is common to the 0V

input to Cn1-2.

・

Check if the wiring is adequately made to CN2-1.

・

Check if DIP-SW1-3 is not changed during the Power Moller

running.

The Power Moller can not be reversed by DIP SW1-3 during

the Power Moller is running. First stop the Power Moller

and then change DIP SW1-3, or use CN2-2 for reversing

direction.

(

9

)

(

8

)

※

PM486FE-60

type

Error can also be reset by shutting off the power for 2second or over.

※1

High voltage may be generated by turning the Power Moller over speed setting.

※1

Max brake torque

2.0 N

・

m

1

(

A

)

Max current

Servo Lock Brake…

※

Discharge

Open

STOP

Discharge

Open

STOP

Discharge

Open

STOP

Discharge

Open

STOP

See section 5

Automatic recovery setting

Automatic recovery setting

Manual recovery setting

Manual recovery setting

MDR connector

unplugged

Shut off the power off

and re-plug connector

properly.

Motor stall for

4 seconds

Inject signal RUN-STOP-RUN order to CN2-1

to reset the error and restart.

Inject signal ON-OFF-ON

or OFF-ON-OFF order to

CN2-2

Inject signal RUN-

STOP-RUN order

to CN2-1

Supply voltage

less than 18VDC.

(Under voltage

error)

Secure the stable

supply voltage 18VDC

or more.

Restart

immediately

Restart

immediately

First secure the stable supply voltage 18VDC

or over, then inject signal RUN-STOP-RUN

order to CN2-1 for error reset and restart.

First secure the stable

voltage 18VDC or over,

then inject signal ON-

OFF-ON or OFF-ON-

OFF order to CN2-2

Inject signal RUN-

STOP-RUN order

to CN2-1 to restart.

Supply voltage

more then 40VDC

for 2sec or 60VDC

for 0.1sec into the

Power Moller.

(Back EFM error)

The voltage into the

Power Moller is less

than 30VDC.

Inject signal RUN-STOP-RUN order to CN2-1

after the voltage into the Power Moller is les

than 30VDC.

Inject signal ON-OFF-

ON or OFF-ON-OFF

order to CN2-2 after

the voltage into the

Power Moller is les

than 30VDC.

Inject signal RUN-

STOP-RUN order

to CN2-1.