44

Ioline FlexJet User Guide

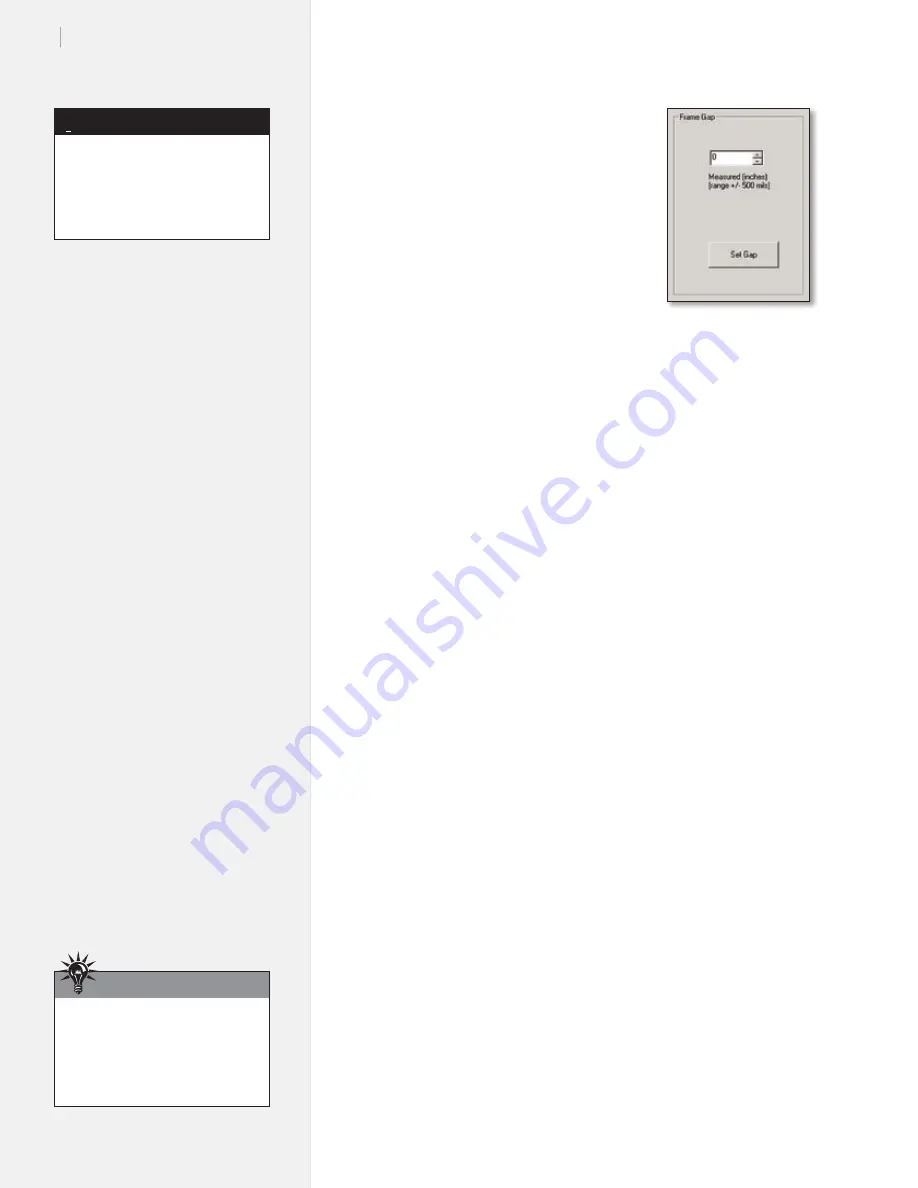

Frame Gap (Paper Scan

Alignment)

1.

Press Select Alignment Plot.

2.

Browse to the

c:\Ioline\Calibration

folder. Select the

40X8.plt

test file.

3.

The

Frame Gap

box has one number

for adjustment. The default value is 0.

4. Changing the values affects the next

scan, created when moving paper

forward through the printer.

5.

Press the

Set Gap

button after mak-

ing adjustments to the values.

Example:

a.

Lines from the next scan have a small space gap between the previous

scan.

b.

Decrease the

Frame Gap

value by 1.

c.

Press the

Set Gap

button.

d.

Repeat the test until alignment is correct.

6.

Click on

Done

when finished.

Figure 32.

The Frame

Gap Box.

Cartridge Maintenance and

Handling

A key to maintaining good print quality is proper print cartridge

maintenance. During printing, ink-spray, paper fibers and dust can

build up on the print cartridge and eventually will degrade plot

quality. In addition, when print cartridges sit inactive for a period of

time, ink may dry in the nozzles and create an ink plug. This results

in the appearance of white streaks in the printed text or graphic.

Check Cartridges

If you experience print quality problems, first verify that the ink

cartridge(s) is undamaged and is not out of ink:

1.

Press the

Start/Stop

key.

2.

If the carriage is parked in the Service Station, use the

Left Ar-

row

key to move it out over the platen.

3. Open a blue stall latch and remove the first cartridge.

4.

Inspect the cartridge for damage and check the ink level indica-

tor. If it is green, the cartridge still contains ink. If it is black, the

cartridge is empty and needs replacing.

5.

Repeat Steps 1–4 for each cartridge stall.

Adding (+) numbers moves the

scans further apart.

Subtracting (-) moves the scans

closer together.

Note

i

Use Best Mode when testing print

quality as the higher resolution

(600 dpi) setting exercises more

nozzles and pushes more ink out

of the cartridge.

Hint