MH860 series hydraulic servo drive

Mechanical installation

15

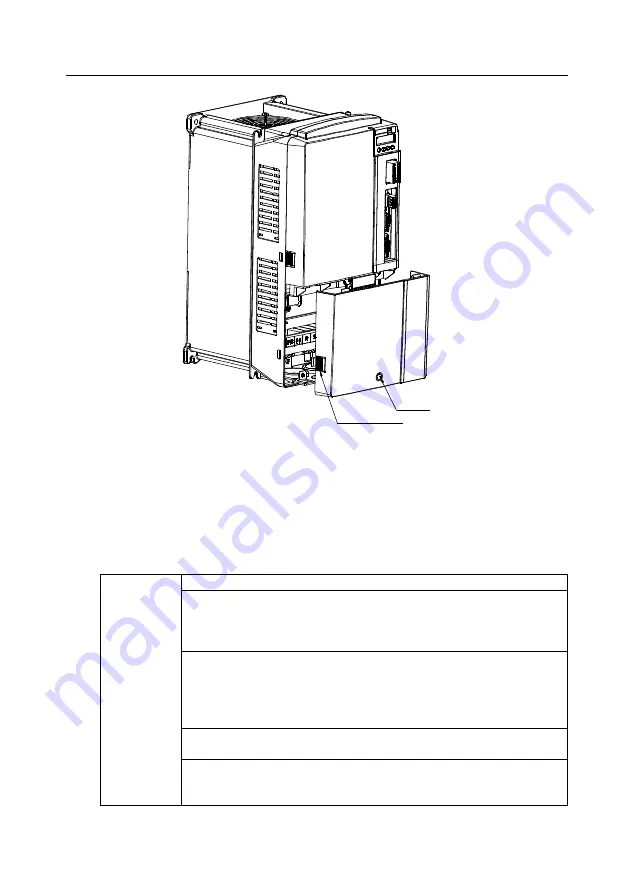

Loosen the screw

Press the snap and gently lift the cover

To assemble the junction box of drive (for example, MH860-T038SF7), do as follows:

1. Put the junction box horizontally into the convex groove, and push the box so that the

junction box and the housing slit overlap.

2. Fasten the two fastening screws of the junction box.

3.4 Installing the motor

To ensure safe and stable running of motor, install the motor according to the following

instructions.

Note

1. Install the motor in the horizontal or vertical direction.

2. When connecting to machinery, it is recommended to use a coupling and

keep the axis of motor in a straight line with the axis of machinery. If the

concentricity is insufficient, vibration may occur, which will cause

damage to shaft bearing or encoder.

3. The motor has positioning requirements for the installation of feedback

elements (such as optical encoder and resolver). To be specific, the

feedback elements are required to have a fixed relative position with the

rotor and stator of motor, which disallows disassembly or swapping

unless authorized.

4. Do not apply tension to cables. Especially the signal cable core is very

thin. Do not stretch it too tightly when wiring.

5. Prevent the shaft bearing from direct impact. Otherwise, the precision

parts on the shaft may be damaged (resolver) or the accuracy may be

degraded.