8

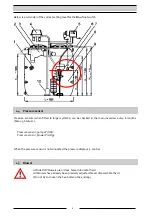

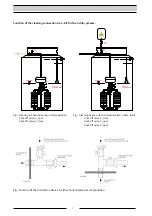

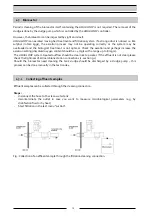

Menu11: Step 4

Chem. liquid filled?

NEXT: menu exit

ENTER: Start cleaning

Chemical

cleaning

routine

for

the

AQUALOOP

system:

A

cleaning

option

is

available

on

the

control

menu

of

the

AQUALOOP

controller

.

A

semi

‐

automatic

cleaning

of

membrane

cartridges

can

be

performed

without

the

need

to

dismount

the

membranes.

Menu

steps

for

cleaning

routine:

Proceed

to

menu

11

1.)

Confirmation

for

starting

the

cleaning

routine

2.)

Controller

automatically

starts

the

sludge

pump

until

the

minimum

level

of

water

is

reached

in

the

bioreactor

(BRmin).

Note:

If

no

internal

sludge

pump

is

connected,

then

the

bioreactor

should

be

pumped

out

with

an

external

(submersible)

pump

until

"BRmin

‐

"

appears

in

the

display

(with

a

simultaneous

sound

of

5

beep

tones)

Attention:

The

suction

pump

(lower

pump)

must

not

be

allowed

to

run

dry!

Also,

lowering

the

water

level

below

will

mean

that

the

system

will

not

re

‐

start

until

the

bioreactor

level

fills

up.

3.)

When

the

controller

shows

"BRmin

‐

",

then

a

backwash

process

is

automatically

performed

to

empty

the

backwash

tank.

This

procedure

ends

automatically

or

can

also

be

terminated

manually.

4.)

Now

the

cleaning

solution

(s.

section

11.6.3)

can

be

added

through

the

cleaning

connection.

In

small

tank

systems

with

good

accessibility

(e.g.

AL

‐

GW200)

the

cleaning

solution

can

be

filled

directly

into

the

backwash

tank.

Note:

The

cleaning

solution

must

be

refilled

during

the

cleaning

process

in

the

case

more

than

three

membranes

are

installed,

as

the

backwash

tank

has

only

6

L

of

capacity

and

each

membrane

requires

2

L

of

cleaning

solution.

5.)

When

the

cleaning

solution

is

filled,

then

the

cleaning

cycle

starts

with

ENTER.

A

pre

‐

set

cleaning

routine

now

runs.

The

routine

takes

about

one

hour.

6.)

After

the

completion

of

the

cleaning

routine

a

clear

water

flush

must

be

started.

At

least

two

litres

of

clear

water

must

be

filled

into

the

backwash

tank

for

each

membrane.

7.)

Press

ENTER

to

confirm

the

clear

water

flush.

The

routine

takes

max.

4

minutes.

Water

that

comes

out

of

the

pipe

must

be

disposed

of.

Menu11:

Chemical cleaning

Next: next menu

ENTER: start

clean

Menu11: Step 1

Chem. cleaning start?

NEXT: exit menu

ENTER: confirm

Menu11: Step 2

Slugepump working

Status: BRmin +

ENTER: exit menu

Menu11: Step 3

Status: BRmin -

Backflush pump

NEXT: abort

backflush

Menu11: Step 5

Cleaning working

Time: 60: 00min

ENTER: exit cleaning

22:08h / A= 4 / 9

T1=05:00h/ T2=16:00h

Air ON/OFF

BRmin + / CLmax

-

Menu11: Step 6

Clearwater filled in?

NEXT: exit flushing

ENTER: start flushing