10 SRPM8 Server System Quick Start Guide

Attach the Rail Slide Rail Brackets to the Equipment Rack

✏

NOTE

Mounting holes in the vertical rails of equipment racks are commonly

spaced in a 5/8 x 5/8 x 1/2-inch sequence. Perform the following steps

carefully; brackets must be mounted with precision to allow room for the

next server you install in a rack.

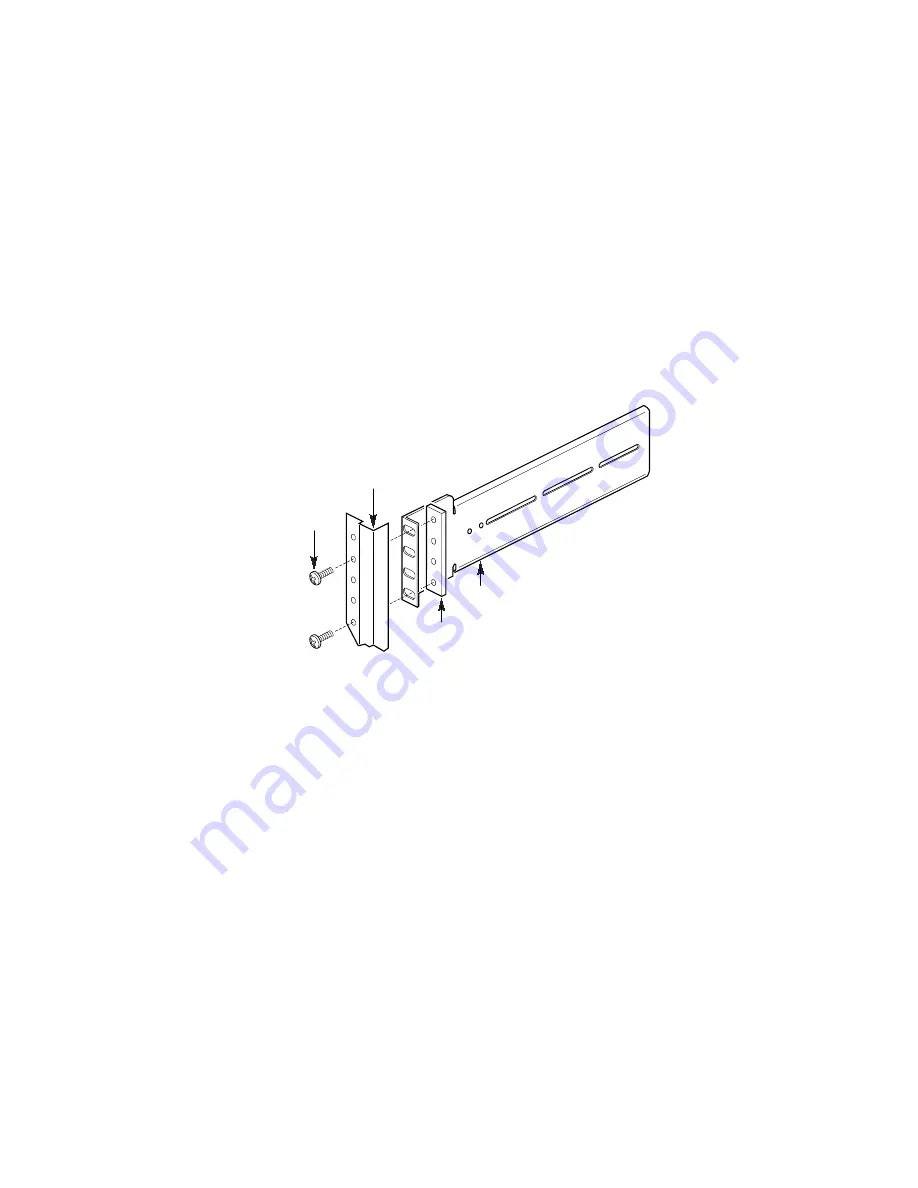

See Figure 6.

1.

Remove a right-angle extension bracket, two screws, and a bar nut from the kit.

2.

While facing the front or back of the rack, orient the right-angle extension bracket so that the

short side with the four mounting holes is facing toward the outside edge of the vertical rail.

3.

Position the bracket behind the mounting holes in the vertical rail.

OM05955

1

4

2

3

Figure 6. Right-angle Bracket and Vertical Rail

A. Screw

B. Vertical

rail

C. Bar

nut

D. Right-angle extension bracket

4.

With a pencil, mark the top and bottom hole locations of the bracket on both sides of the

vertical rail; no hole numbers are printed on the rail.

5.

Insert a screw through the marked top hole in the rail and through the top hole in the bracket.

Place a bar nut on the screw and loosely tighten it. Repeat for the marked bottom hole.

6.

Install the three remaining right-angle extension brackets on the other three vertical rails by

repeating steps 1–5 above.