18-CE01D1-1F-EN

25

General Venting

FURNACE EXHAUST MUST BE VENTED TO THE OUTDOORS. THESE

FURNACES ARE INDUCED DRAFT VENTED AND MUST

NOT

BE

CONNECTED TO ANY VENT SERVING ANOTHER APPLIANCE. PLEASE

NOTE THAT THESE FURNACES USE

POSITIVE-PRESSURE

VENT

SYSTEMS.

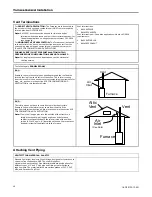

Proper venting is essential to obtain maximum efficiency from a

condensing Furnace. Proper installation of the vent system is

necessary to assure drainage of the condensate and prevent

deterioration of the vent system.

ETL has certified the design of condensing Furnaces for a minimum of

0" clearance from combustible materials to single wall plastic vent

pipe.

The recommended system is assembled from 2" or 3" plastic pipe and

fittings found in the Approved Vent Pipe Materials Table. Where the

system is routed to the outdoors through an existing masonry

chimney containing flue products from another gas appliance, or

where required by local codes, then 3" venting of Type 29- 4C

stainless steel must be used in place of PVC material.

These Furnaces have been classified as CATEGORY IV Furnaces in

accordance with ANSI Z21.47 “latest edition” standards. Category IV

Furnaces operate with positive vent pressure and with a vent gas

temperature less than 140°F above the dewpoint. These conditions

require special venting systems, which must be gas tight and water

tight.

Note:

When an existing Furnace is removed from a venting system

serving other gas appliances, the venting system is likely to be

too large to properly vent the remaining attached appliances.

Important:

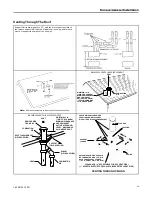

These Furnaces may be installed as Direct Vent (sealed

combustion) or as Nondirect Vent (single pipe). The

Furnaces are shipped DIRECT VENT with sealed

combustion.

Important:

Products installed in Canada must use vent systems that

are certified to the Standard for Type BH Gas Venting

Systems (ULC S636) for Class II-A venting systems (up

to 65°C). Components of the vent system must not be

interchanged with other vent systems or unlisted pipe or

fittings. Plastic components, specified primers, and glues

must be from a single system manufacturer and not

intermixed with other system manufacturer's vent

system parts. In addition, the first three feet of the vent

pipe must be visible for inspection.

3” Venting requirements

Important:

To determine if your application requires 3” venting, see

the Maximum Vent Length Table.

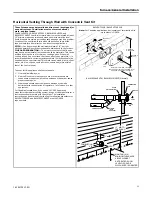

Important:

Horizontal venting application must use the 2” x 3” offset

reducing coupling. Vertical venting applications to not

require the reducing coupling to be offset.

When the vent pipe is exposed to temperatures below

freezing, e.g., when it passes through unheated spaces, etc.,

the pipe must be insulated with 1/2 inch (22.7 mm) thick

Armaflex-type insulation or equal.

If the space is heated sufficiently to prevent freezing, then the

insulation will not be required. If domestic water pipes are not

protected from freezing then the space meets the condition of

a heated space.

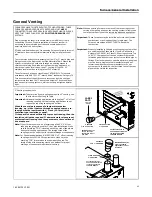

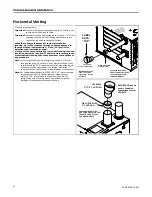

Note:

If your furnace comes with a factory supplied 2" X 3" offset

reducing coupling it is used for 3" vent pipe installation. Make

sure the marking "TOP" is located on the top side of the pipe in

horizontal venting applications. The straight side of the

coupling must be on bottom for proper drainage of condensate.

Note:

For Canadian applications, BAYREDUCE 2” x 3” offset reducing

coupling meets ULC-S636 requirements. Make sure the

marking "TOP" is located on the top side of the pipe. The

straight side of the coupling must be on bottom for proper

drainage of condensate in horizontal venting.

FIELD SUPPLIED

2” COUPLING

LABEL

SAYS

“TOP”

2" TO 3" COUPLING

CPL00938

BAYREDUCE may be

used in Canadian

applications to meet

ULC-S636

CPL00938 IS FACTORY

SUPPLIED ONLY WITH THE

120,000 BTUH UPFLOW

FURNACE MODELS

FIELD SUPPLIED

2” COUPLING

2" TO 3" COUPLING

CPL00938 IS FACTORY

SUPPLIED ONLY WITH THE

120,000 BTUH UPFLOW

FURNACE MODELS

CPL00938

BAYREDUCE may be

used in Canadian

applications to meet

ULC-S636

F

Fu

urrn

na

acce

e G

Ge

en

ne

erra

all IIn

nsstta

alllla

attiio

on

n

Summary of Contents for S9V2B040D3PSBA

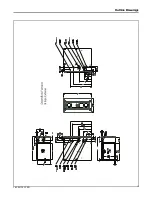

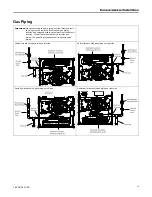

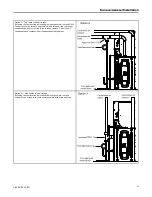

Page 12: ...12 18 CE01D1 1F EN Outline Drawings...

Page 13: ...18 CE01D1 1F EN 13 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 14: ...14 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 15: ...18 CE01D1 1F EN 15 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 16: ...16 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 17: ...18 CE01D1 1F EN 17 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...