©2017 Ingersoll Rand All rights reserved

18-CE01D1-1F-EN

SAFETY SECTION— FURNACES

IIn

ng

ge

errsso

ollll R

Ra

an

nd

d h

ha

ass a

a p

po

olliiccy

y o

off cco

on

nttiin

nu

uo

ou

uss p

prro

od

du

ucctt

a

an

nd

d p

prro

od

du

ucctt d

da

atta

a iim

mp

prro

ov

ve

em

me

en

ntt a

an

nd

d iitt rre

esse

errv

ve

ess tth

he

e

rriig

gh

htt tto

o cch

ha

an

ng

ge

e d

de

essiig

gn

n a

an

nd

d ssp

pe

ecciiffiicca

attiio

on

nss w

wiitth

ho

ou

utt

n

no

ottiicce

e..

IIm

mp

po

orrtta

an

ntt:: — This document pack contains a wiring

diagram and service information. This is

customer property and is to remain with

this unit. Please return to service

information pack upon completion of work.

W

WA

AR

RN

NIIN

NG

G

F

FIIR

RE

E O

OR

R E

EX

XP

PL

LO

OS

SIIO

ON

N H

HA

AZ

ZA

AR

RD

D!!

Failure to follow safety warnings exactly

could result in a fire or explosion causing

property damage, personal injury or loss

of life.

—

— D

Do

o n

no

ott sstto

orre

e o

orr u

usse

e g

ga

asso

olliin

ne

e o

orr o

otth

he

err

fflla

am

mm

ma

ab

blle

e v

va

ap

po

orrss a

an

nd

d lliiq

qu

uiid

dss iin

n tth

he

e v

viicciin

niitty

y o

off

tth

hiiss o

orr a

an

ny

y o

otth

he

err a

ap

pp

plliia

an

ncce

e.. —

— W

WH

HA

AT

T T

TO

O D

DO

O IIF

F

Y

YO

OU

U S

SM

ME

EL

LL

L G

GA

AS

S

••

D

Do

o n

no

ott ttrry

y tto

o lliig

gh

htt a

an

ny

y a

ap

pp

plliia

an

ncce

e..

••

D

Do

o n

no

ott tto

ou

ucch

h a

an

ny

y e

elle

eccttrriicca

all ssw

wiittcch

h;;d

do

o n

no

ott u

usse

e

a

an

ny

y p

ph

ho

on

ne

e iin

n y

yo

ou

urr b

bu

uiilld

diin

ng

g..

••

IIm

mm

me

ed

diia

atte

elly

y cca

allll y

yo

ou

urr g

ga

ass ssu

up

pp

plliie

err ffrro

om

m a

a

n

ne

eiig

gh

hb

bo

orr’’ss p

ph

ho

on

ne

e.. F

Fo

ollllo

ow

w tth

he

e g

ga

ass ssu

up

pp

plliie

err''ss

iin

nssttrru

uccttiio

on

nss..

••

IIff y

yo

ou

u cca

an

nn

no

ott rre

ea

acch

h y

yo

ou

urr g

ga

ass ssu

up

pp

plliie

err,, cca

allll

tth

he

e ffiirre

e d

de

ep

pa

arrttm

me

en

ntt..

—

— IIn

nsstta

alllla

attiio

on

n a

an

nd

d sse

errv

viicce

e m

mu

usstt b

be

e p

pe

errffo

orrm

me

ed

d

b

by

y a

a q

qu

ua

alliiffiie

ed

d iin

nsstta

alllle

err,, sse

errv

viicce

e a

ag

ge

en

nccy

y,, o

orr tth

he

e

g

ga

ass ssu

up

pp

plliie

err..

W

WA

AR

RN

NIIN

NG

G

E

EX

XP

PL

LO

OS

SIIO

ON

N H

HA

AZ

ZA

AR

RD

D!!

F

Fa

aiillu

urre

e tto

o ffo

ollllo

ow

w tth

hiiss w

wa

arrn

niin

ng

g cco

ou

ulld

d rre

essu

ulltt iin

n

p

prro

op

pe

errtty

y d

da

am

ma

ag

ge

e,, p

pe

errsso

on

na

all iin

njju

urry

y o

orr d

de

ea

atth

h..

IIn

nsstta

allll a

a g

ga

ass d

de

ette

eccttiin

ng

g w

wa

arrn

niin

ng

g d

de

ev

viicce

e iin

n cca

asse

e o

off a

a

g

ga

ass lle

ea

akk..

N

NO

OT

TE

E:: T

Th

he

e m

ma

an

nu

uffa

accttu

urre

err o

off y

yo

ou

urr ffu

urrn

na

acce

e

d

do

oe

ess n

no

ott tte

esstt a

an

ny

y d

de

ette

ecctto

orrss a

an

nd

d m

ma

akke

ess n

no

o

rre

ep

prre

esse

en

ntta

attiio

on

nss rre

eg

ga

arrd

diin

ng

g a

an

ny

y b

brra

an

nd

d o

orr tty

yp

pe

e o

off

d

de

ette

ecctto

orr..

W

WA

AR

RN

NIIN

NG

G

E

EX

XP

PL

LO

OS

SIIO

ON

N H

HA

AZ

ZA

AR

RD

D!!

F

Fa

aiillu

urre

e tto

o ffo

ollllo

ow

w tth

hiiss w

wa

arrn

niin

ng

g cco

ou

ulld

d rre

essu

ulltt iin

n

p

prro

op

pe

errtty

y d

da

am

ma

ag

ge

e,, p

pe

errsso

on

na

all iin

njju

urry

y o

orr d

de

ea

atth

h..

N

Ne

ev

ve

err u

usse

e a

an

n o

op

pe

en

n fflla

am

me

e tto

o d

de

ette

ecctt g

ga

ass lle

ea

akkss..

E

Ex

xp

pllo

ossiiv

ve

e cco

on

nd

diittiio

on

nss m

ma

ay

y o

occccu

urr.. U

Usse

e a

a lle

ea

akk tte

esstt

sso

ollu

uttiio

on

n o

orr o

otth

he

err a

ap

pp

prro

ov

ve

ed

d m

me

etth

ho

od

dss ffo

orr lle

ea

akk

tte

essttiin

ng

g..

W

WA

AR

RN

NIIN

NG

G

E

EL

LE

EC

CT

TR

RIIC

CA

AL

L S

SH

HO

OC

CK

K,, F

FIIR

RE

E,, O

OR

R

E

EX

XP

PL

LO

OS

SIIO

ON

N H

HA

AZ

ZA

AR

RD

D!!

F

Fa

aiillu

urre

e tto

o ffo

ollllo

ow

w tth

hiiss W

Wa

arrn

niin

ng

g cco

ou

ulld

d rre

essu

ulltt iin

n

d

da

an

ng

ge

erro

ou

uss o

op

pe

erra

attiio

on

n,, p

prro

op

pe

errtty

y d

da

am

ma

ag

ge

e,, sse

ev

ve

erre

e

p

pe

errsso

on

na

all iin

njju

urry

y,, o

orr d

de

ea

atth

h..

IIm

mp

prro

op

pe

err sse

errv

viicciin

ng

g cco

ou

ulld

d rre

essu

ulltt iin

n d

da

an

ng

ge

erro

ou

uss

o

op

pe

erra

attiio

on

n,, p

prro

op

pe

errtty

y d

da

am

ma

ag

ge

e,, sse

ev

ve

erre

e p

pe

errsso

on

na

all

iin

njju

urry

y,, o

orr d

de

ea

atth

h..

••

B

Be

effo

orre

e sse

errv

viicciin

ng

g,, d

diisscco

on

nn

ne

ecctt a

allll e

elle

eccttrriicca

all

p

po

ow

we

err tto

o ffu

urrn

na

acce

e..

••

W

Wh

he

en

n sse

errv

viicciin

ng

g cco

on

nttrro

ollss,, lla

ab

be

ell a

allll w

wiirre

ess p

prriio

orr

tto

o d

diisscco

on

nn

ne

eccttiio

on

n.. R

Re

ecco

on

nn

ne

ecctt w

wiirre

ess cco

orrrre

eccttlly

y..

••

V

Ve

erriiffy

y p

prro

op

pe

err o

op

pe

erra

attiio

on

n a

afftte

err sse

errv

viicciin

ng

g..

W

WA

AR

RN

NIIN

NG

G

C

CA

AR

RB

BO

ON

N M

MO

ON

NO

OX

XIID

DE

E P

PO

OIIS

SO

ON

NIIN

NG

G

H

HA

AZ

ZA

AR

RD

D!!

F

Fa

aiillu

urre

e tto

o ffo

ollllo

ow

w tth

hiiss W

Wa

arrn

niin

ng

g cco

ou

ulld

d rre

essu

ulltt iin

n

p

prro

op

pe

errtty

y d

da

am

ma

ag

ge

e,, sse

ev

ve

erre

e p

pe

errsso

on

na

all iin

njju

urry

y,, o

orr

d

de

ea

atth

h..

T

To

o e

en

nssu

urre

e ffu

urrn

na

acce

e iiss v

ve

en

ntte

ed

d p

prro

op

pe

errlly

y,, d

do

o n

no

ott

rre

ep

plla

acce

e ffa

acctto

orry

y ssu

up

pp

plliie

ed

d v

ve

en

nttiin

ng

g cco

om

mp

po

on

ne

en

nttss w

wiitth

h

ffiie

elld

d ffa

ab

brriicca

atte

ed

d p

pa

arrttss.. F

Fa

ab

brriicca

attiin

ng

g p

pa

arrttss cca

an

n rre

essu

ulltt

iin

n d

da

am

ma

ag

ge

ed

d v

ve

en

nttss a

an

nd

d cco

om

mp

po

on

ne

en

nttss a

allllo

ow

wiin

ng

g

cca

arrb

bo

on

n m

mo

on

no

ox

xiid

de

e tto

o e

esscca

ap

pe

e tth

he

e v

ve

en

nttiin

ng

g ssy

ysstte

em

m..

W

WA

AR

RN

NIIN

NG

G

C

CA

AR

RB

BO

ON

N M

MO

ON

NO

OX

XIID

DE

E H

HA

AZ

ZA

AR

RD

D!!

F

Fa

aiillu

urre

e tto

o ffo

ollllo

ow

w tth

hiiss W

Wa

arrn

niin

ng

g cco

ou

ulld

d rre

essu

ulltt iin

n

p

prro

op

pe

errtty

y d

da

am

ma

ag

ge

e,, sse

ev

ve

erre

e p

pe

errsso

on

na

all iin

njju

urry

y,, o

orr

d

de

ea

atth

h..

D

Do

o n

no

ott a

atttte

em

mp

ptt tto

o cch

ha

an

ng

ge

e tth

he

e v

ve

en

nttiin

ng

g ssy

ysstte

em

m..

F

Fo

ollllo

ow

w tth

he

e iin

nsstta

alllla

attiio

on

n a

an

nd

d o

op

pe

erra

attiio

on

n iin

nssttrru

uccttiio

on

nss

ffo

orr tth

he

e v

ve

en

nttiin

ng

g ssy

ysstte

em

m..

Summary of Contents for S9V2B040D3PSBA

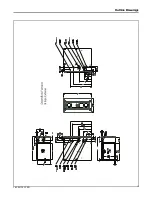

Page 12: ...12 18 CE01D1 1F EN Outline Drawings...

Page 13: ...18 CE01D1 1F EN 13 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 14: ...14 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 15: ...18 CE01D1 1F EN 15 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 16: ...16 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 17: ...18 CE01D1 1F EN 17 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...