18-CE01D1-1F-EN

23

Gas Valve Adjustment

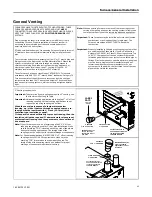

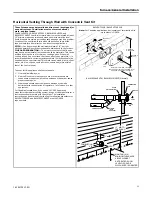

Changes can be made by adjusting the manifold pressure, or changing

orifices (orifice change may not always be required). To adjust the

manifold pressure:

1.

Turn off all electrical power to the system.

2.

Attach a manifold pressure gauge with flexible tubing to the outlet

pressure boss marked "OUT P" on White- Rodgers gas valve

model 36J.

3.

Loosen (Do Not remove) the pressure tap test set screw one turn

with 3/32" hex wrench.

a.

The pressure tap adjustment kit (KIT07611) contains a 3/32"

hex wrench, a 5/16" hose and a connector and can be

ordered through Global Parts.

4.

Turn on system power and energize valve.

5.

Adjust 1st stage gas heat by removing the low (LO) adjustment

regulator cover screw.

a.

To increase outlet pressure, turn the regulator adjust screw

clockwise.

b.

To decrease outlet pressure, turn the regulator adjust screw

counterclockwise.

c.

Adjust regulator until pressure shown on manometer

matches the pressure specified in the table.

The input of no more than nameplate rating and no less than

93% of the nameplate rating, unless the unit is derated for

high altitude.

d.

Replace and tighten the regulator cover screw securely.

6.

Adjust 2nd stage gas heat by removing the high (HI) adjustment

regulator cover screw.

a.

To increase outlet pressure, turn the regulator adjust screw

clockwise.

b.

To decrease outlet pressure, turn the regulator adjust screw

counterclockwise.

c.

Adjust regulator until pressure shown on manometer

matches the pressure specified in the table.

The input of no more than nameplate rating and no less than

93% of the nameplate rating, unless the unit is derated for

high altitude.

d.

Replace and tighten the regulator cover screw securely.

7.

Cycle the valve several times to verify regulator setting.

a.

Repeat steps 5-7 if needed.

8.

Turn off all electrical power to the system.

9.

Remove the manometer and flexible tubing and tighten the

pressure tap screw.

10. Using a leak detection solution or soap suds, check for leaks at the

pressure outlet boss and pressure tap test screw.

11. Turn on system power and check operation of the unit.

Fuel Manifold Pressure Settings (inches w.c.)

Fuel

2nd Stage Max.

1st Stage Max.

Natural Gas

3.5” W.C.

1.7” W.C.

LP Gas

10.0” W.C.

6.0” W.C.

F

Fu

urrn

na

acce

e G

Ge

en

ne

erra

all IIn

nsstta

alllla

attiio

on

n

Summary of Contents for S9V2B040D3PSBA

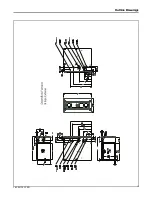

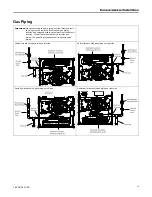

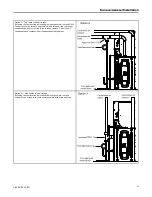

Page 12: ...12 18 CE01D1 1F EN Outline Drawings...

Page 13: ...18 CE01D1 1F EN 13 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 14: ...14 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 15: ...18 CE01D1 1F EN 15 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 16: ...16 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 17: ...18 CE01D1 1F EN 17 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...