SECTION 5 - OPERATION

Operating & Maintenance Manual

43

Before Starting

• Open service valve(s) to ensure pressure

is relieved in receiver-separator system.

Close valve(s) in order to build up full air

pressure and ensure proper oil

circulation.

• Check battery for proper connections and

condition.

• Check battery for proper connections and

condition.

• Check engine coolant level.

WARNING

!

Do not remove pressure cap from

a HOT radiator. Allow radiator to

cool down before removing

pressure cap. Use extreme care

when removing a pressure cap

from a liquid cooling system for

the engine. The sudden release of

pressure from a heated cooling

system can result in a loss of

coolant and possible severe

personal injury.

• Check the engine oil level. Maintain per

marks on dipstick.

• Check the fuel level. Add only CLEAN

DIESEL fuel for maximum service from

the engine.

• Check the compressor lubricating fluid

level between bottom and midway of the

sight glass on the separator tank.

WARNING

!

This machine produces loud noise

with doors open. Extended exposure

to loud noise can cause hearing loss.

Wear hearing protection when doors

or valve (s) are open.

• Close all doors to maintain a cooling air

path and to avoid recirculation of hot air.

This will maximize the life of the engine

and compressor and protect the hearing

of surrounding personnel.

• Be sure no one is IN or ON the

compressor unit.

WARNING

!

Unrestricted air flow from a hose will

result in a whipping motion of the

hose which can cause severe injury or

death. A safety device must be

attached to the hose at the source of

supply to reduce pressure in case of

hose failure or other sudden pressure

release. Reference: OSHA regulation

29 CFR Section 1926.302 (b).

Starting

• Turn the POWER switch to “ON”.

• Turn Power switch to “START”

position to crank engine. Hold switch

in “START” position for

approximately 5 seconds after engine

starts.

Summary of Contents for P185AWIR

Page 6: ...1 4...

Page 7: ...3 FOREWORD...

Page 8: ...4...

Page 10: ...6...

Page 11: ...7 DRAWBAR NOTICE...

Page 12: ...Operating Maintenance Manual 8...

Page 14: ...Operating Maintenance Manual 10...

Page 15: ...11 Section 1 Safety...

Page 19: ...Safety Operating Maintenance Manual 15...

Page 20: ...Operating Maintenance Manual Safety 16...

Page 22: ...Operating Maintenance Manual Safety 18...

Page 23: ...Safety Operating Maintenance Manual 19...

Page 25: ...21 Section 2 WARRANTY...

Page 30: ...Operating Maintenance Manual WARRANTY 26...

Page 32: ...Operating Maintenance Manual WARRANTY 28...

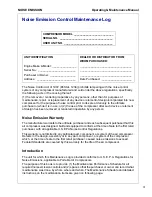

Page 33: ...29 Section 3 NOISE EMISSION...

Page 39: ...35 Section 4 GENERAL DATA...

Page 42: ...Operating Maintenance Manual GENERAL DATA 38...

Page 43: ...39 SECTION 5 OPERATION...

Page 51: ...47 Section 6 MAINTENANCE...

Page 59: ...55 Section 7 LUBRICATION...

Page 61: ...57 Section 8 Trouble Shooting...