51

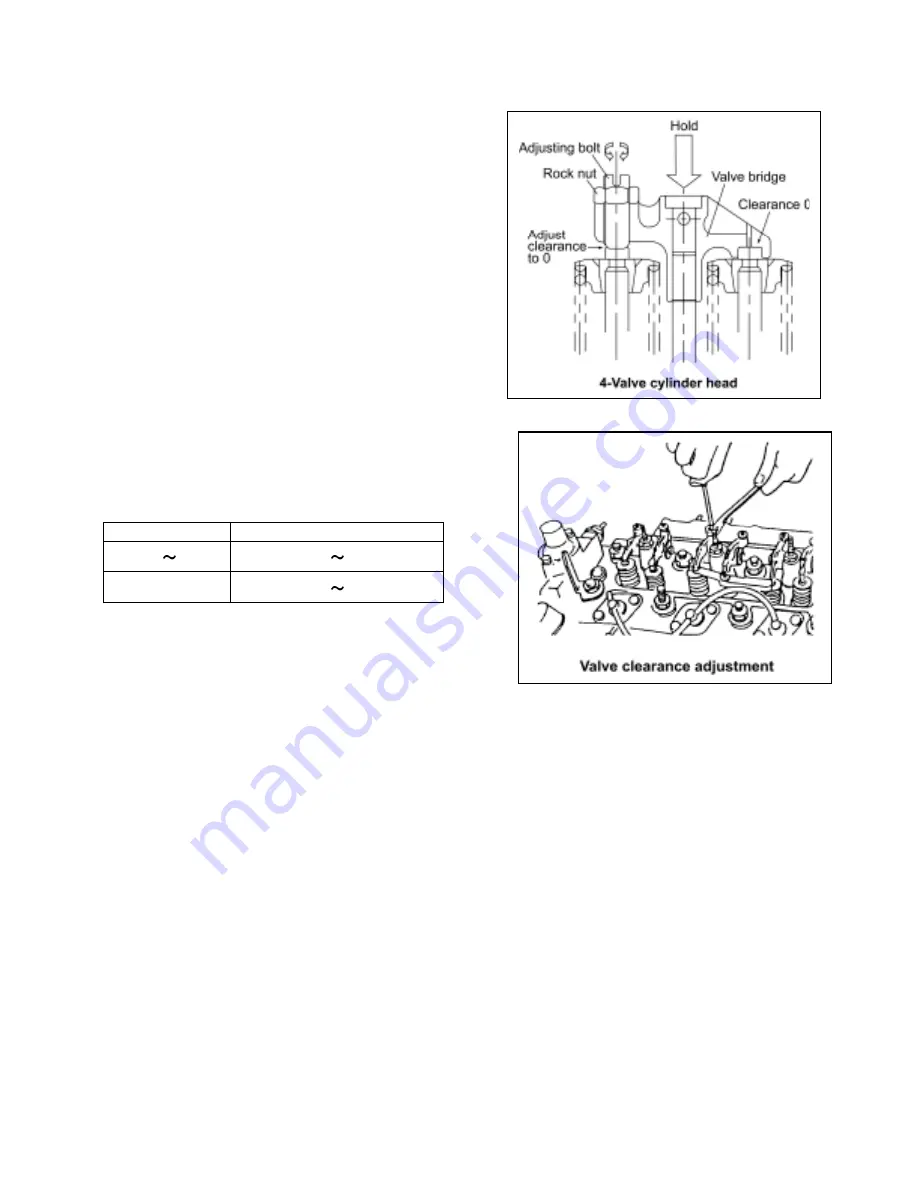

Push the bridge head so that a valve bridge and

two valve stem heads may contact each other

uniformly, and adjust an adjusting bolt so that a

gap of the valve stem head may become 0.

Tighten a locknut after a valve bridge is fixed with

a wrench.

2) Measuring valve clearance

Insert a 0.2 or 0.3 mm thickness gage between

the rocker arm and valve cap / valve bridge, and

adjust the valve clearance. Tighten the adjusting

screw.

mm

Model

Standard valve clearance

3IRH2N 8N

0.15 0.25

4IRI8T

0.25 0.35

[NOTICE]

When tightening a valve bridge locknut of 4-valve

head, tighten a locknut after fixing a valve bridge

with a wrench so that a bridge may not rotate and a

valve may not lean.

3) Apply oil to the contact surface between adjusting

screw and push rod.

4) Adjusting other cylinders

In case of 4-cylinder engines turn the crankshaft 180°

then and make adjustment for the No.3 cylinder. Then

adjust the No.4 and No.2 cylinders in this order.

The cylinder to be adjusted first does not have to be the

No.1 cylinder. Select and adjust the cylinder where the

piston is the nearest to the top dead center after turning,

and make adjustment for other cylinders in the order of

ignition by turning the crankshaft 180° each time.

In case of 3-cylinder engines turn the crankshaft 240° then

and make adjustment for the No.3 cylinder. Then adjust the

No.2 cylinder in this order.

The cylinder to be adjusted first does not have to be the No.1

cylinder. Select and adjust the cylinder where the piston is

the nearest to the top dead center after turning, and make

adjustment for other cylinders in the order of ignition by

turning the crankshaft 240° each time.