40 |

www.HandiQuilter.com

6.

Retighten the six bottom side extrusion screws.

7. Check the machine to see if it still rocks, if so, repeat the process.

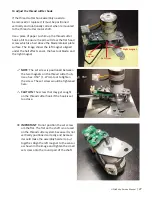

9. Rear Axle and Axle Housings

A special alignment tool is used to press the wheels onto the axle hubs to prevent the wheels from

wobbling during factory assembly. A special shaft coupler with a slit in it is used to join the two rear axles

to keep the Y-axis encoder working properly. The shaft coupler also provides for adjusting the proper width

between the wheels for alignment to the carriage tracks. The machine encoder is mounted to this rear axle

assembly up under the machine to hide and protect the encoder.

NOTE

: The wheels are fixed to the machine

with screws that use a 4mm hex tool.

NOTE

: You can use the 16mm (5/8") thin

frame wrench (QM09318-114) to hold

the rear long or short shaft axles while

tightening or loosenin the rear wheel

retaining screw if necessary.

Differences between the four wheel axle housings

Each of the four wheel bases is unique because they each have a unique purpose. The front two housings

are for regular type wheels, like the ones used on other HQ machines. They are mounted with screws but

do not have axles with hubs like the rear wheels.

The rear axle housings are machined differently for the axles with hubs.

The right two housings, one front and one rear, also have a flat cut out on them for the HQ Pro-Stitcher

Y-rack, as well as have elongated mounting holes. The elongated holes are for adjusting the width between

the left and right wheels to align the machine wheels to the carriage if needed.