25

STNM ed 07/07

NIKE Mini Export

Technical Documentation

Technical Documentation

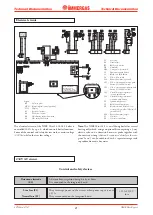

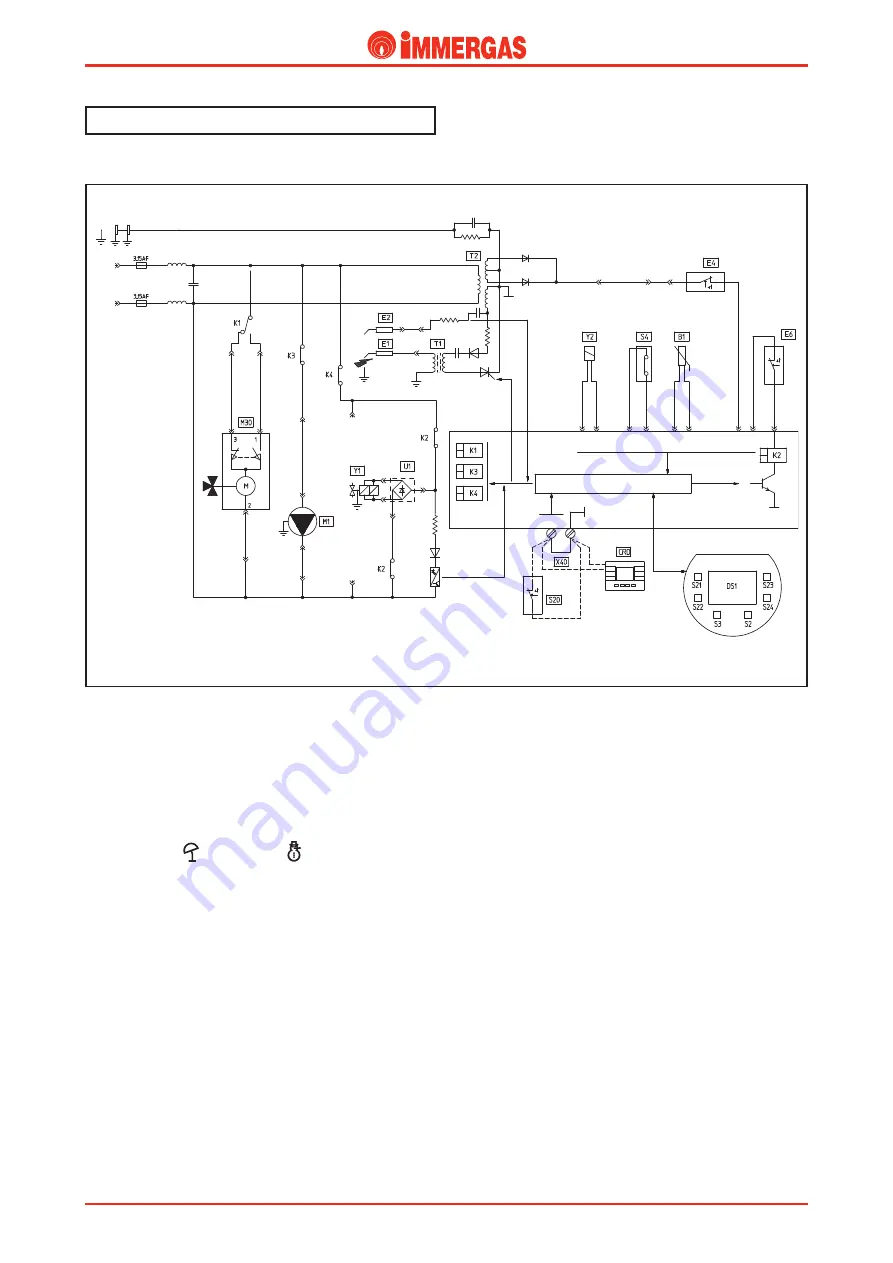

Electrical circuit.

D.h.w. phase.

(*) depending on the gas valve used, the main coils are powered

at mains voltage (SIT 845) or at mains voltage rectified by a

diode bridge (U1) housed in the valve connector (Honeywell

VK4105).

Operation.

By selecting the

(Summer) or (Winter), functioning

mode with the (S2) push button, the boiler is enabled to work

in the d.h.w. mode.

When some domestic hot water is drawn it causes the contact

of the d.h.w. flow switch (S4) to close. Subsequently, if the

temperature measured by the NTC delivery probe (B1) is below

the d.h.w. value set on the boiler’s control panel

(or on the CRD

if mounted)

, the integrated board powers the boiler circulator

(M1) by means of the K3 relay and, with the deviation of the

K1 relay contact, powers the motor (M) of the 3-way valve

(M30) which keeps working until limit switch “3” opens when

the d.h.w. position is reached.

The integrated board, enabled by the safety thermostat (E4)

and fumes thermostat (E6), closes the contact of the request

relay K2 that causes the 2 contacts to close which allows the

ignition cycle to start, first of all triggering the ignition elec-

trode (E1) and then both the gas valve coils (Y1).

Burner ignition is detected by the integrated board by means

of the ionisation electrode (E2).

�

�����

�

���������������

����

�������

���

�������

����������������������������

��������������