9

1-7

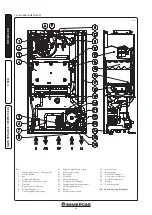

2

1

1-8

1-9

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

1.7 IMMERGAS FLUE SYSTEMS.

Immergas supplies various solutions separately

from the boilers regarding the installation of air

intake terminals and flue extraction, which are

fundamental for boiler operation.

Attention: the boiler must only be installed

together with an original Immergas air intake

and flue gas exhaust system, in compliance

with the standards in force. This system can be

identified by an identification mark and special

distinctive marking bearing the note " not for

condensing boilers".

The flue exhaust pipes must not be in contact with

or be near to flammable materials. Moreover,

they must not pass through buildings or walls

made of flammable material.

See following paragraphs for the detailed

description of the kits available.

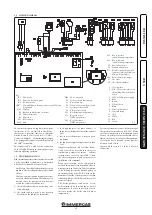

Positioning of double lip seals.

For correct

positioning of lip seals on elbows and extensions,

follow the direction of assembly given in figure

(Fig. 1-7).

• Resistance factors and equivalent lengths.

Each flue component has a

Resistance Factor

based on experimental tests and specified

in the table below. The Resistance Factor for

individual components is independent from

the type of boiler on which it is installed

and has a dimensionless size. It is however,

conditioned by the temperature of the fluids

that pass through the pipe and therefore,

varies according to applications for air intake

or flue exhaust. Each single component has a

resistance corresponding to a certain length

in metres of pipe of the same diameter; the

so-called equivalent length, obtained from

the ration between the relative Resistance

Factors.

All boilers have an experimentally

obtainable maximum Resistance Factor equal to

100.

The maximum Resistance Factor allowed

corresponds to the resistance encountered with

the maximum allowed pipe length for each

type of Terminal Kit. This information allows

calculations to be made to verify the possibility

of setting up various flue configurations.

•

Coupling of extension pipes. To install any

push-fit extensions with other flue extraction

elements, it is necessary to do the following:

install the concentric pipe or elbow with the

male side (smooth) on the female section

(with lip seal) to the end stop on the previously

installed element. This will ensure the sealing

and joining of the elements correctly.

Attention:

if the exhaust terminal and/or

extension concentric pipe needs shortening,

consider that the internal duct must always

protrude by 5 mm with respect to the external

duct.

Diaphragm installation.

Attention:

based on the boiler model (checking

which type of fan is installed), use appropriate

diaphragms.

For correct functioning of the boiler it is

necessary to install a diaphragm on the outlet

of the sealed chamber and before the intake

and exhaust pipe. The appropriate diaphragm is

chosen based on type of pipe and its maximum

extension: this calculation can be made using

the tables below:

N.B.:

the diaphragms are supplied together with

the boiler.

Key:

1 - Concentric

flue extraction

diaphragm

2 - Divided flue

extraction

diaphragm

Diaphragm

(ref. 1 fig. 1-8)

Pipe extension in metres

Ø

60/100 horizontal

Ø 85

From 0 to 0.5

Ø 83

From 0.5 to 1.5

WITHOUT

Exceeding 1.5

Diaphragm

(ref. 1 fig. 1-8)

Pipe extension in metres

Ø

60/100 vertical

Ø 85

From 0 to 2.2

Ø 83

From 2.2 to 3.7

WITHOUT

Exceeding 3.7

Diaphragm

(ref. 1 fig. 1-8)

Pipe extension in metres

Ø

80/125 horizontal

Ø 85

From 0 to 0.5

Ø 83

From 0.5 to 4.6

WITHOUT

Exceeding 4.6

Diaphragm

(ref. 1 fig. 1-8)

Pipe extension in metres

Ø

80/125 vertical

Ø 85

From 0 to 5.4

Ø 83

From 5.4 to 9.5

WITHOUT

Exceeding 9.5

Diaphragm

(ref. 2 fig. 1-8)

Pipe extension in metres

Ø

80 divided

intake

exhaust

Ø 20.5

From 0.5 to 15

1

Ø 15

From 15 to 35

1

Diaphragm

(ref. 2 fig. 1-8)

Pipe extension in metres

Ø

80 divided

intake

exhaust

Ø 20.5

1

From 0.5 to 8

Ø 15

1

From 8 to 16

WITHOUT

1

Exceeding 16

Diaphragm

(fig. 1-9)

Pipe extension in metres

Ø

60/100 horizontal

Ø 40

From 0 to 0.5

Ø 41.5

From 0.5 to 1.5

WITHOUT

Over 1.5

Diaphragm

(fig. 1-9)

Pipe extension in metres

Ø

60/100 vertical

Ø 40

From 0 to 2.2

Ø 41.5

From 2.2 to 3.2

WITHOUT

Over 3.2

Diaphragm

(fig. 1-9)

*Extension in metres

horizontal pipe Ø 80 with

two bends

Ø 40

From 0 to 17

Ø 41.5

From 17 to 24

WITHOUT

Over 24

Diaphragm

(fig. 1-9)

*Extension in metres

vertical pipe Ø 80

without bends

Ø 40

From 0 to 22

Ø 41.5

From 22 to 29

WITHOUT

Over 29

Diaphragm

(fig. 1-9)

Pipe extension in metres

Ø

80/125 horizontal

Ø 40

From 0 to 0.5

Ø 41.5

From 0.5 to 3.3

WITHOUT

Over 3.3

Diaphragm

(fig. 1-9)

Pipe extension in metres

Ø

80/125 vertical

Ø 40

From 0 to 5.4

Ø 41.5

From 5.4 to 8.1

WITHOUT

Over 8.1

DIAPHRAGM

*

The values for maximum length are considered

with 1 metre of exhaust pipe and the remaining

on intake.

FAN POWER:

33W / 39W (Fig. 1-9).

FAN POWER: 30W (Fig. 1-8).

Summary of Contents for MINI EOLO 24 3E

Page 1: ...MINI EOLO 24 3E Instruction and warning book 1 038773ENG ...

Page 2: ......

Page 28: ...28 3 5 4 4 5 6 6 d d c INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 33: ...33 ...

Page 34: ...34 ...

Page 35: ...35 ...