13

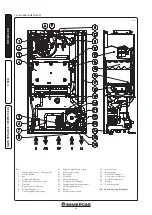

C12

1-18

C12

1-19

1

3

2

5 6

4

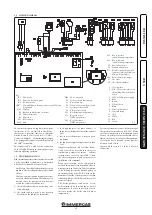

C32

1-21

1-20

C32

1

2

3

4

6

5

7

8

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

The kit includes:

N°1 - Gasket (1)

N°1 - Concentric bend Ø 60/100 (2)

N°1 - Adapter Ø 60/100 for

Ø 80/125 (3)

N°1 - Concentric terminal

int./exh. Ø 80/125 (4)

N°1 - Internal wall sealing plate (5)

N°1 - External wall sealing plate (6)

The kit includes:

N°1 - Gasket (1)

N°1 - Female flange

concentric (2)

N°1 - Adapter Ø 60/100)

for Ø 80/125 (3)

N°1 - Wall sealing plate (4)

N°1 - Aluminium tile (5)

N°1 - Concentric pipe

int./exh. Ø 80/125 (6)

N°1 - Fixed half-shell

N°1 - Mobile half-shell

1.11 CONCENTRIC VERTICAL KIT

INSTALLATION.

Type C configuration, sealed chamber and

fan assisted.

Concentric vertical intake and exhaust kit. This

vertical terminal is connected directly to the

outside of the building for air intake and flue

exhaust.

N.B.:

the vertical kit with aluminium tile

enables installation on terraces and roofs with

a maximum slope of 45% (approx 25°) and the

height between the terminal cap and half-shell

(374 mm) must always be observed.

Vertical kit with aluminium tile Ø 80/125.

Kit

assembly (Fig. 1-20): install the concentric flange

(2) on the central hole of the boiler inserting the

gasket (1) and tighten using the screws in the

kit. Fit the male end (smooth) of the adapter (3)

into the female end of the concentric flange (2).

Imitation aluminium tile installation. Replace the

tile with the aluminium sheet (5), shaping it to

ensure that rainwater runs off. Position the fixed

half-shell (7) and insert the intake-exhaust pipe

(6). Fit the Ø 80/125 concentric terminal pipe

with the male end (6) (smooth) to the female end

of the adapter (3) (with lip gasket) up to the stop;

making sure that the wall sealing plate (4) has

been fitted, this will ensure sealing and joining

of the elements making up the kit.

The vertical kit with this configuration can be

extended to

a max. straight vertical length of

12200 mm

including the terminal (Fig. 1-21).

This configuration corresponds to a resistance

factor of 100. In this case the special extensions

must be requested.

The terminal Ø 60/100 can also be used for

vertical exhaust, in conjunction with concentric

flange code 3.011141 (sold separately).

The vertical kit with this configuration can be

extended to

a max. straight vertical length of 4700

mm

including the terminal (Fig. 1-21).

MAXIMU

M

LEN

GTH

4700

mm

MAXIMU

M

LEN

GTH

12200

mm

Summary of Contents for MINI EOLO 24 3E

Page 1: ...MINI EOLO 24 3E Instruction and warning book 1 038773ENG ...

Page 2: ......

Page 28: ...28 3 5 4 4 5 6 6 d d c INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 33: ...33 ...

Page 34: ...34 ...

Page 35: ...35 ...