21

2-2

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

Insufficient circulation.

This occurs if the boiler

overheats due to insufficient water circulating in

the primary circuit (code 27); the causes can be:

- low system circulation; check that no shut-off

devices are closed on the heating circuit and

that the system is free of air (deaerated);

- circulating pump blocked; free the circulating

pump.

If this phenomenon occurs frequently, contact

a qualified technician for assistance (e.g.

Authorized After-Sales Technical Assistance

Service).

Loss of Remote Control communication.

This occurs 1 minute after communication

loss between the boiler and the remote control

(code 31). To reset the error code, switch

voltage to the boiler off and then back on

again. If this phenomenon occurs frequently,

contact a qualified technician for assistance (e.g.

Authorized After-Sales Technical Assistance

Service).

Low power supply voltage.

This occurs when

the power supply voltage is lower than the

allowed limits for the correct functioning of

the boiler. If normal conditions are restored,

the boiler re-starts without having to be reset.

If this phenomenon occurs frequently, contact

a qualified technician for assistance (e.g.

Authorized After-Sales Technical Assistance

Service).

Loss of flame signal.

This occurs when the

boiler is ignited correctly and the burner flame

switches off unexpectedly; a new attempt at

ignition is performed and if normal conditions

are restored, the boiler does not have to be

reset. If this phenomenon occurs frequently,

contact a qualified technician for assistance (e.g.

Authorized After-Sales Technical Assistance

Service).

Block due to loss of continuous flame signal.

This occurs if the "Flame signal loss" error occurs

6 times consecutively in 8.5 minutes (38)”. To

eliminate the block, the Reset button (1) must be

pressed. If this phenomenon occurs frequently,

contact a qualified technician for assistance (e.g.

Authorized After-Sales Technical Assistance

Service).

2.6 BOILER SHUTDOWN

For complete boiler switch-off, press the “off”

button, disconnect the onmipolar switch outside

of the boiler and close the gas cock upstream

from the appliance. Never leave the boiler

switched on if left unused for prolonged periods.

2.7 RESTORE HEATING SYSTEM

PRESSURE

Periodically check the system water pressure.

The boiler manometer should read a pressure

between 1 and 1.2 bar.

If the pressure is below 1 bar (with the circuit cool)

restore normal pressure via the cock located in the

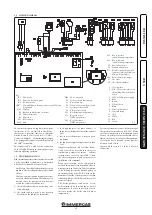

lower part of the boiler (Fig. 2-2).

N.B.:

close the cock after the operation.

If pressure values reach around 3 bar the safety

valve may be activated.

In this case contact a professional technician

for assistance.

In the event of frequent pressure drops, contact

qualified staff for assistance to eliminate the

possible system leakage.

2.8 DRAINING THE SYSTEM.

To drain the boiler, use the special draining

valve (Fig. 2-2).

Before draining, ensure that the filling valve is

closed.

2.9 ANTI-FREEZE PROTECTION.

The boiler has an anti-freeze function that

switches on automatically when the temperature

falls below 4°C (standard protection to minimum

temperature of -5°C). In order to guarantee

the integrity of the appliance and the domestic

hot water heating system in zones where the

temperature falls below zero, we recommend

the heating system is protected using anti-freeze

liquid and installation of the Immergas Anti-

freeze Kit in the boiler (Par. 1.3). In the case

of prolonged inactivity (second case), we also

recommend that:

- the electric power supply is disconnected;

- the heating circuit and boiler domestic water

circuit must be drained. In systems that are

drained frequently, filling must be carried

out with suitably treated water to eliminate

hardness that can cause lime-scale.

2.10 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the boiler casing. Never use abrasive or powder

detergents.

2.11 DECOMMISSIONING.

In the event of permanent shutdown of the boiler,

contact professional staff for the procedures and

ensure that the electrical, water and gas supply

lines are shut off and disconnected.

Key:

1 - Filling valve

2 - Draining valve

Bottom view.

Summary of Contents for MINI EOLO 24 3E

Page 1: ...MINI EOLO 24 3E Instruction and warning book 1 038773ENG ...

Page 2: ......

Page 28: ...28 3 5 4 4 5 6 6 d d c INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 33: ...33 ...

Page 34: ...34 ...

Page 35: ...35 ...