26

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

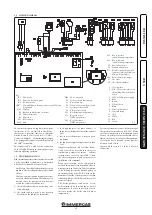

3.8 POSSIBLE ADJUSTMENTS

N.B.:

to adjust the gas valve, remove the plastic

cap (6); after adjusting, refit the cap.

• Preliminary calibration operations.

- Set parameter P4 at 0 %.

- Set parameter P5 at 99 %.

• Activate the chimney sweep function.

- Enter the “DHW chimney sweep” mode,

opening a DHW cock.

• Adjustment of boiler nominal thermal heat

output.

- Set the maximum output (99%) using the

buttons (5 and 6 Fig. 2-1).

- From the brass nut (3 Fig. 3-3) adjust

the boiler nominal output, observing the

maximum pressure values stated in the table

(Par. 3.18 / 3.21) according to the type of

gas; by turning clockwise the heat potential

increases, anti-clockwise it decreases.

• Adjustment of boiler minimum thermal heat

output.

N.B.:

only proceed after having calibrated the

nominal pressure.

- Set the minimum output (0%) using the

buttons (5 and 6 Fig. 2-1).

- Adjust the minimum thermal input by

operating on the cross plastic screws (2)

on the gas valve maintaining the brass nut

blocked (3);

Exit the “Chimney sweep” mode and keep the

boiler functioning.

• Adjustment of the boiler minimum heat output

in heating phase.

N.B.:

only proceed after having calibrated the

minimum boiler pressure.

- To adjust the minimum heat output during

the heating phase, change parameter (P4),

increasing the value the pressure increases,

reducing it the pressure drops.

- The pressure to which the boiler minimum

heat output must be adjusted, must not be

lower than that stated in the tables (Par. 3.18

/ 3.21).

• Adjustment (any) of the boiler maximum heat

output in heating phase.

- To adjust the maximum heat output during

the heating phase, change parameter (P5),

increasing the value the pressure increases,

reducing it the pressure drops.

- The pressure to which the boiler maximum

heat output must be adjusted in central

heating phase, must not be carried out in

reference to that stated in the tables (Par. 3.18

/ 3.21).

3.9 AUTOMATIC SLOW IGNITION

FUNCTION WITH TIMED RAMP

DELIVERY.

In ignition phase, the P.C.B. supplies constant

gas with pressure proportional to the parameter

"G2" set.

3.10 "CHIMNEY SWEEP FUNCTION".

When activated, this function forces the boiler

to variable output for 15 minutes.

In this state all adjustments are excluded

and only the safety thermostat and the limit

thermostat remain active. To activate the

chimney sweep function, press the Reset button

(1) for 8 seconds in absence of DHW requests,

its activation is signalled by the indication of

the flow temperature and the flashing

and

symbols.

This function allows the technician to check

the combustion parameters. Once the function

is activated, it is possible to select whether to

perform the check in CH status, regulating the

parameters with buttons (5 and 6) or in DHW

mode opening any DHW cock and always

regulate the parameters with the buttons (5

and 6).

Functioning in CH or DHW mode is visualised

by the relative flashing symbols

or

.

On completion of the checks, deactivate the

function by pressing the Reset button (1) for

8 seconds.

3.11 PUMP ANTI-BLOCK FUNCTION.

The boiler has a function that starts the pump

once every 24 hours for the duration of 30

seconds in order to reduce the risk of the pump

becoming blocked due to prolonged inactivity.

3.12 THREE-WAY ANTI-BLOCK SYSTEM.

The boiler is supplied with a function that

activates the motorised three-way unit every 24

hours, carrying out a complete cycle in order

to reduce the risk of three-way block due to

prolonged inactivity.

3.13 RADIATORS ANTI-FREEZE

FUNCTION.

If the system return water is below 4°C, the boiler

starts up until reaching 42°C.

3.14 P.C.B. PERIODICAL SELF-CHECK.

During functioning in heating mode or with

boiler in standby, the function activates every 18

hours after the last boiler check/power supply. In

case of functioning in domestic hot water mode

the self-check starts within 10 minutes after the

end of the withdrawing in progress, for duration

of approx. 10 seconds.

N.B.:

during self-check, the boiler remains off,

including signalling.

3.15 SOLAR PANELS COUPLING

FUNCTION.

The boiler is set-up to receive pre-heated water

from a system of solar panels up to a maximum

temperature of 65°C. In all cases, it is always

necessary to install a mixing vale on the hydraulic

circuit upstream from the boiler on the cold

water inlet.

Note:

for good functioning of the boiler; the

temperature selected on the solar valve must

be 5°C greater with respect to the temperature

selected on the boiler control panel.

For correct use of the boiler in this condition,

parameter P3 (DHW thermostat) must be set at

“1” and the parameter P9 (DHW ignition delay)

at a temperature sufficient to receive water from

a storage tank situated upstream from the boiler.

The greater the distance from the storage tank,

the longer the stand-by time to be set. When

these regulations have been performed, when

the boiler inlet water is at the same or greater

temperature with respect to that set by the DHW

selector switch, the boiler does not switch on.

Summary of Contents for MINI EOLO 24 3E

Page 1: ...MINI EOLO 24 3E Instruction and warning book 1 038773ENG ...

Page 2: ......

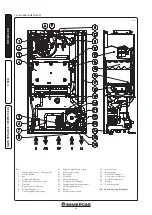

Page 28: ...28 3 5 4 4 5 6 6 d d c INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 33: ...33 ...

Page 34: ...34 ...

Page 35: ...35 ...