EN – Oil Free Silent Air Compressor

046 ‐ LI ‐SP‐EN‐ GENERAL SILENCIOSOS REV 171121

20 / 24

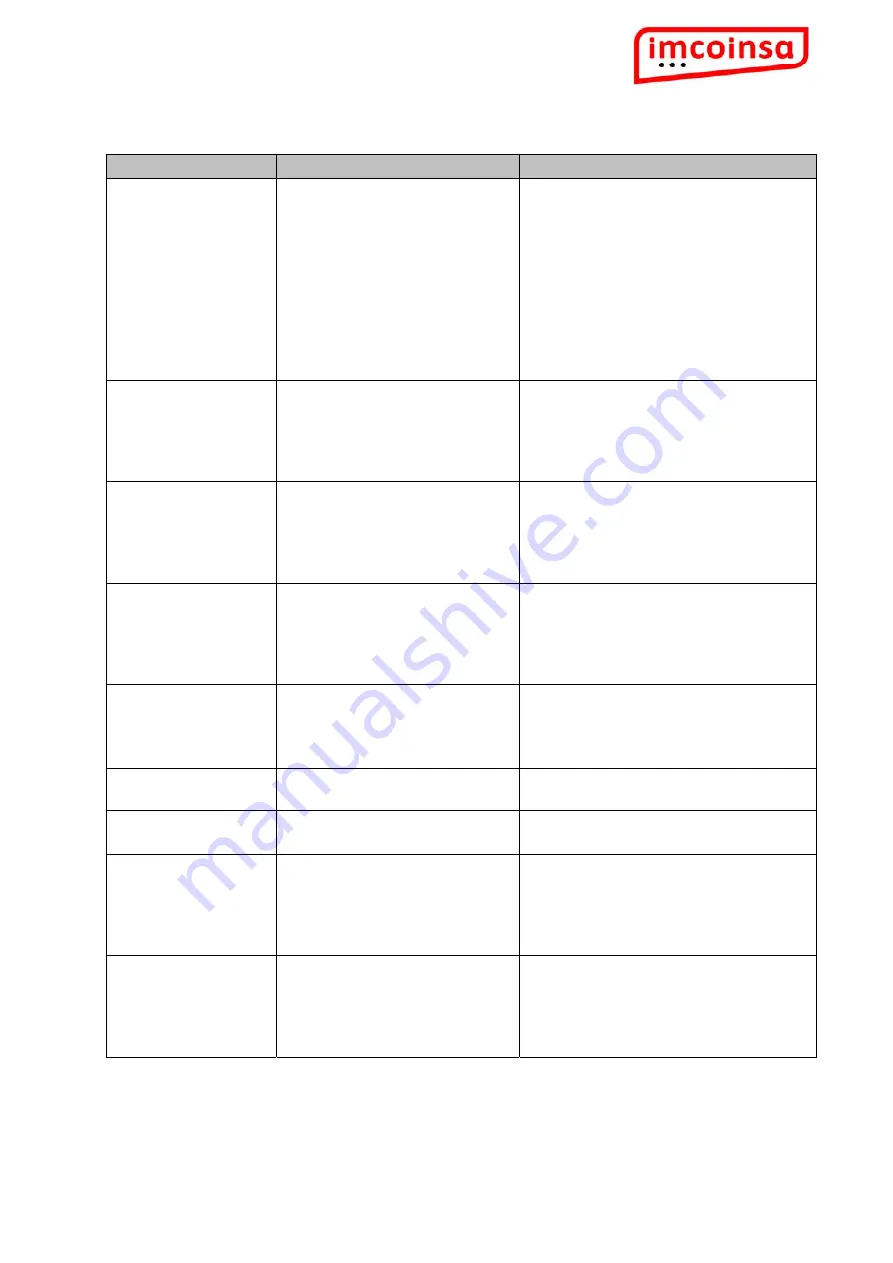

9.‐ POSSIBLE FAULTS AND TROUBLE SHOOTING

Symptom

Possible Cause(s)

Corrective action

Compressor stops

running or does not

start.

1. Fuse blown or circuit breaker

tripped.

2. Loose electrical connections.

3. Overheated motor.

4. Main supply with inadequate

Voltage.

5. Motor windings burnt out.

1. Check for cause of blown fuse/breaker

and replace or reset.

2. Check wiring connections.

3. Press the reset button or wait for

automatic reset.

4. Check that the main voltage

corresponds to specifications. An

extension cable, which is too thin, and

too long can cause a voltage drop.

5. Contact the nearest Technical Service.

Tank pressure drops

down.

1. Air leak.

2. Air filter blocked.

3. Defective check valve.

1. Find and repair leak.

2. Clean and / or replace cartridge.

3. Check valve could be dirty, clean and

check it, if the problem persists, replace

check valve.

Safety valve releasing.

1. Defective pressure switch or

improper adjustment.

2. Safety valve does not work

properly.

1. Check adjustment of pressure switch

and replace in case the problem persists.

2. Check valve manually by pulling

upward on rings. In case the problem

persists, replace defective valve.

Solenoid valve leaks

when compressor is in

standby.

Defective non‐return valve seal.

Let the air in the tank Flow out until all

the pressure is released. Then remove

the non‐return valve plug and clean the

valve seat. If necessary replace the seal

and the re‐mount all the components.

The motor does not

start or makes a

humming noise.

Capacitor burnt out.

Replace starter capacitor.

Metallic noise.

Compressor head gasket is

broken, or valve faulty.

Stop the compressor and contact the

nearest Technical Service.

Compressor does not

reach desire pressure.

Compressor head gasket is

broken, or valve faulty.

Stop the compressor and contact the

nearest Technical Service.

Low compressed air

flow.

1. Pressure switch needs to be

adjusted.

2. Water from condensate in

receiver.

1. Stop the compressor and contact the

nearest Technical Service.

2. Open the ball valve and release the

pressure. Open the drain valve and

release the water.

Pump does not stop

when the tank

pressure reaches its

maximum working

pressure.

Defective pressure switch or

needs adjusting

Stop the compressor and contact the

nearest Technical Service.