8

Adhesive

rubber

4. Measurement and recording

Preparing to measure

•

It may not be possible to measure if the sample gas quantity is less than 10mL.

•

A measurement can be taken even if the inside of the sample is depressurized, but if the

package’s internal pressure is less than -30kPa, a correct measurement value may not be

obtained. Note that depressurization will occur easily after gas suction, especially if the gas

quantity is low. In this case, a measurement can be taken using the optional “gas sampling

glass tube (model: GS-2)”.

•

The measurement may take longer if the inside of the sample is depressurized.

•

A measurement can be taken even if the inside of the sample is pressurized. However, if

the package’s internal pressure is higher than +40kPa, the components could break when

the needle is pierced, or a correct measured value may not be obtained. In this case, a

measurement can be taken using the optional “gas sampling glass tube (model: GS-2)”.

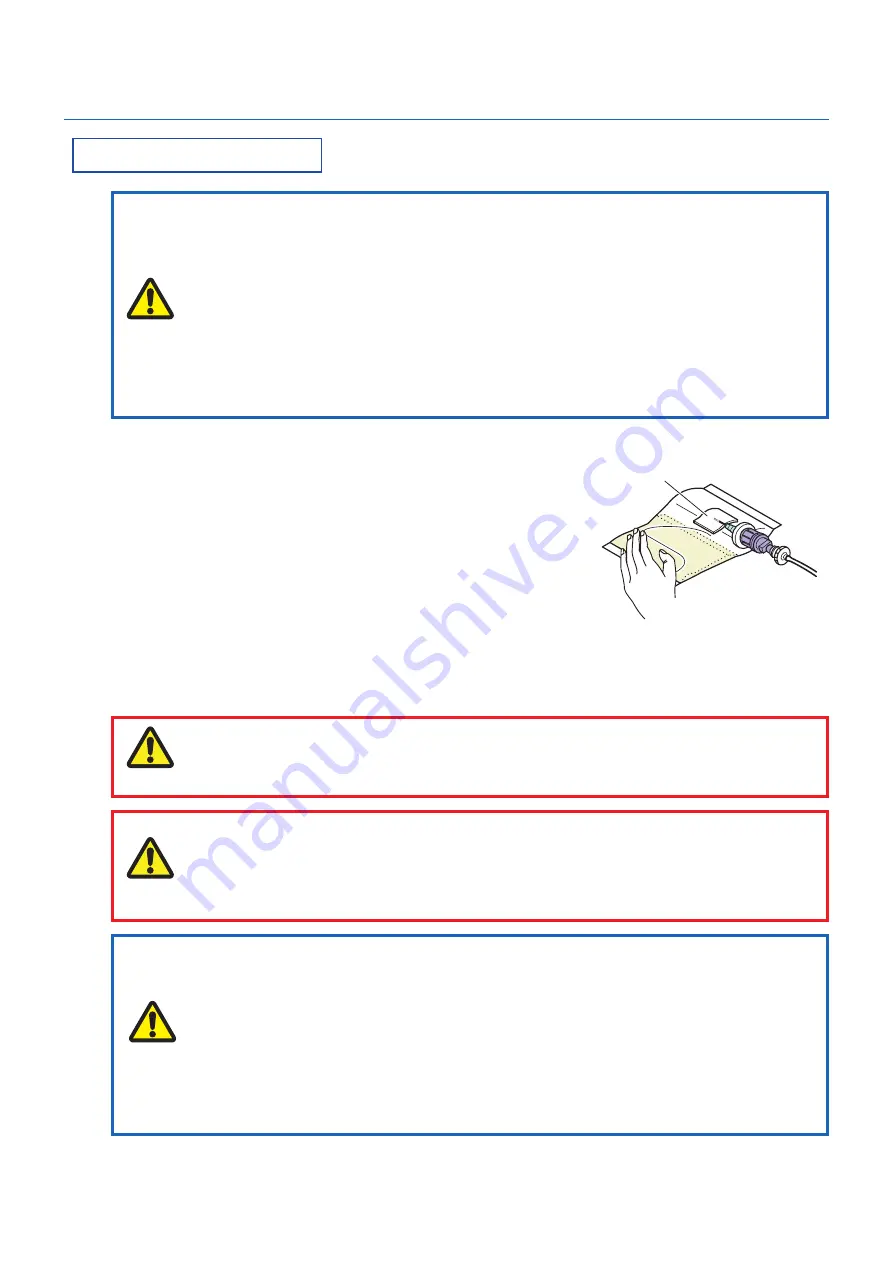

1.

Shift the contents in the pack to one side and hold with a

hand to create a space for piercing the needle.

2.

Attach the enclosed adhesive rubber over the air space.

Adhesive rubber cutting dimension reference: 1cm x 1 cm square

3.

Lightly press down on one side of the bag, and set the

needle in the sample gas.

Do not suction the contents.

A measurement error will occur if powder, etc., gets clogged in the needle.

Note that the minute amount of liquid in the sample gas is blocked by the membrane filter.

Warning

Take care not to stab the human body with the needle. There is a risk of blindness, puncture

wounds, or cuts.

•

If pressure is applied into the pack from the set needle using an air gun, etc., the internal

pump or sensor could be damaged. If the needle is clogged, replace it with a new needle.

•

Continuing use with a clogged needle, membrane filter, check valve, or sampling tube with

fitting will deteriorate the sensor.

•

If the liquid is accidentally suctioned, the membrane filter that has absorbed the liquid will not

pass the gas, preventing a correct measurement. Note that if the liquid contains oil, it might

pass through the membrane filter. Refer to “Maintenance” (pages 26 to 27) and replace

the needle, membrane filter, check valve, and sampling tube with fitting contaminated with

liquid or oil with new parts. Check the housing to confirm that the suctioned liquid and oil

have not adhered to the oxygen sensor. If adhered, remove the oxygen sensor and clean

the inside of the housing. The metal mesh at the front center of the oxygen sensor can be

cleaned by lightly wiping with tissue paper.

•

Using the needle, membrane filter, check valve, and sampling tube with fitting in a clogged

state may prevent a correct measurement.

Caution

Note

Note