33

Relay Test Function

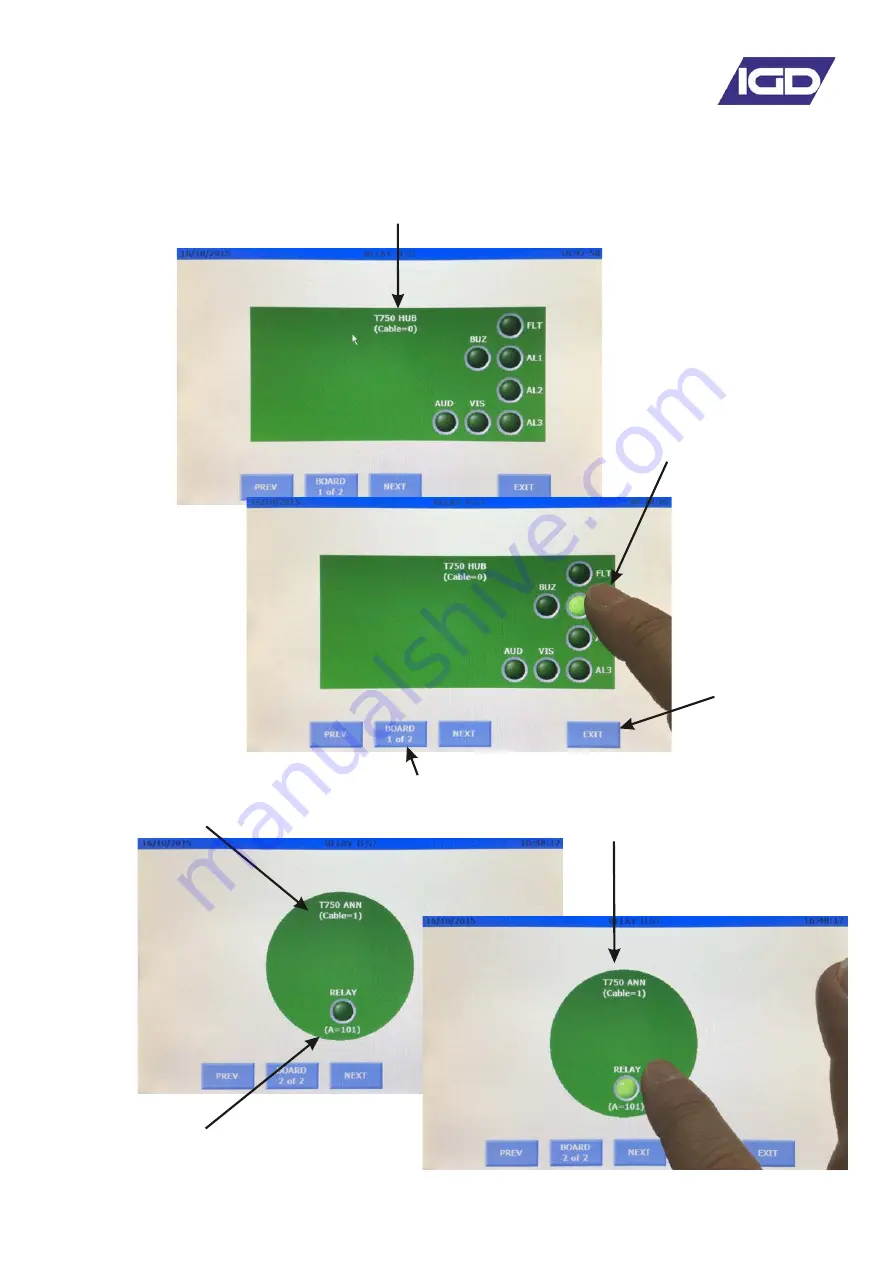

The Tocsin750 has the option to run a relay test function. Select the option and the following

screen is displayed.

Note the outputs on the hub card are always indicated first

Select the relay to test to

see it change its state

Use the NEXT and PREV buttons to select the desired relay

board.

There are also screen displays for individual ‘module’ outputs.

Use EXIT to

return to the

main menu and

release all

selected relays

back to normal

operation.

Aelay Address

Cable Highway