16

xtra

-

Installation & Servicing

INSTALLATION

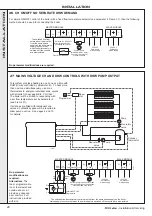

REAR VIEW

Flue

Sampling

Point

Air inlet duct O110

A

F

B

C

D

E

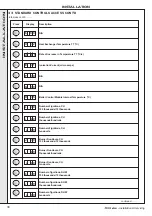

See Table on page 5 for guidance on maximum permissible

flue and air duct system design.

FLUE

Construct either the horizontal or vertical combined flue outlet

ductwork to create the manifold arrangement depicted. The

horizontal combined flue outlet can be installed with its outlet

facing left or right dependent upon the demands of each

particular installation.

A tube of ductwork seal lubricant is provided within the flue kit.

To ease flue connections lubricate all flue seals before

assembly. Flue sampling points are fitted within the ductwork

legs A and B as depicted to facilitate flue products sampling of

each boiler module.

IMPORTANT NOTES.

1.

The flue manifold should be supported in such a way as

not to place load on the boiler module flue outlet sockets.

Propriety flue duct brackets must be used to provide

support as appropriate.

2.

Unless the connecting flue is manufactured from

aluminium the condensate generated within the flue must

be collected and drained before entering the combined flue

outlet ductwork. When employing the vertical combined

flue outlet header, a flue condensate drain is provided for

this purpose.

12 FLUE / AIR DUCT INSTALLATION

KEY

A

Flue Tube

D

Bend x 45

o

B

Flue Tube

E

Connector

C

Bend x 87

o

F

Adaptor

REAR VIEW

Flue

Sampling

Point

A

D

B

C

im9161

Air inlet duct O110

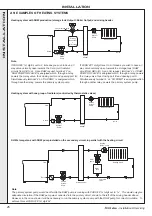

AIR DUCT

Combustion air can be drawn directly from the boiler room

using the high level air inlet kit provided or ducted in from

outside the building in which the boiler is installed.

IMPORTANT NOTE. If combustion air is drawn from within the

boiler room, ensure no dust or airborne debris can be

ingested into the appliance. Dusty concrete flooring should

be sealed to reduce the presence of dust. Ideally where

possible duct the air supply into the boiler room from a clean

source outside the boiler room / building.

To draw air direct from outside, connection can be made using

separate ducts to each boiler Module. This can be done using

any propriety 110mm soil / drain pipe. Expansion to a larger

diameter may be required to reduce resistance, dependant on

total flue / air duct lengths required. (See Flue System Design

on Page 5). The air duct should be terminated with a suitable

fixed grille to prevent entry to vermin. This terminal should be

positioned as such to avoid blockages or entry of water.

An optional RS duct connector kit allows for the two individual

module air inlet connections to be combined into a single

200mm boiler air supply connection to simplify installation and

increase permissible air duct length (F320 and F400 only)

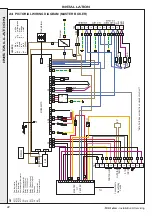

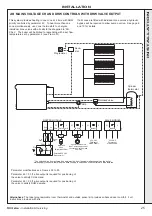

HORIZONTAL FLUE HEADER ARRANGEMENT

KEY

A

Flue Tube

C

Flue Tee Manifold

B

Flue Tube

D

Flue Condensate Drain Trap

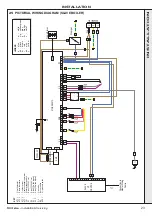

VERTICAL FLUE HEADER ARRANGEMENT

INST

ALLA

TION