40

xtra

-

Installation & Servicing

SERVICING

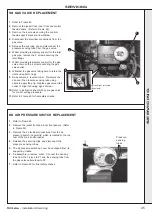

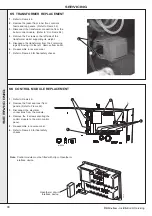

51 GAS VALVE ADJUSTMENT

The boiler contains 2 Modules with individual gas valves. Both

must be adjusted.

Maximum rate adjustment

1.

Switch the boiler on and operate for 10 minutes.

2.

To ensure the boiler operates at maximum rate without

modulating set the fan speeds to maximum.

3.

Remove the outer fascia panel on the Slave Module (see

Frame 52).

4.

To set the fan speed to maximum. Press and hold in the

'mode' and '+' buttons simultaneously on the Master

Module. The display will show as the first digit

indicating the boiler is operating at maximum rate.

Repeat on the Slave Module.

5.

Connect a suitable flue analyser to the flue sampling point

of the Master Module (see Frame 12).

6.

Using the maximum rate adjustment screw, adjust the

master module gas valve until the CO

2

measures 9.7% ±

0.2 (nb. clockwise reduces CO

2

).

7.

Connect a suitable flue analyser to the flue sampling point

of the Slave Module (see Frame 12).

8.

Using the maximum rate adjustment screw, adjust the

Slave Module gas valve until the CO

2

measures 9.7% ± 0.2

(nb. clockwise reduces CO

2

).

H

L

Maximum Rate Adjustment Screw

(Firstly remove plastic cap for access)

Minimum rate adjustment

9.

To ensure the boiler operates at minimum rate without

modulating, set the fan speeds to minimum.

10.

To set the fan speed to minimum. Press and hold in the

'mode' and '-' buttons simultaneously on the Master

Module. The display will show as the first digit

indicating the boiler is operating at minimum rate.

Repeat on the Slave Module.

11.

Connect a suitable flue analyser to the flue sampling point

of the Master Module - see Frame 12.

12.

Remove the protective cap and then using the offset

adjustment screw, adjust the valve on the master module

until the CO

2

value measures 9.5% ± 0.2 (nb. anti-

clockwise reduces CO

2

level). The offset adjustment is a

lot more sensitive than the throttle adjustment.

13.

Connect a suitable flue analyser to the flue sampling point

on the Slave Module (see Frame 12).

14.

Remove the protective cap and then using the offset

adjustment screw, adjust the valve on the Slave Module

until the CO

2

value measures 9.5% ± 0.2 (nb. anti-

clockwise reduces CO

2

level).

15.

Re-check the CO

2

level at maximum rate and repeat steps

3 to 15 if necessary.

16.

Press the '+' and '-' buttons simultaneously to return to

normal operating mode.

17.

Seal adjustment screw with tamper proof paint.

Note.

It is possible to switch off the CH/DHW systems if the mode and +/- buttons are not held simultaneously. Refer to Frame 30

under the heading CH/DHW Systems for guidance.

Offset Adjustment Screw

(Firstly remove plastic cap for access)

SER

VICING