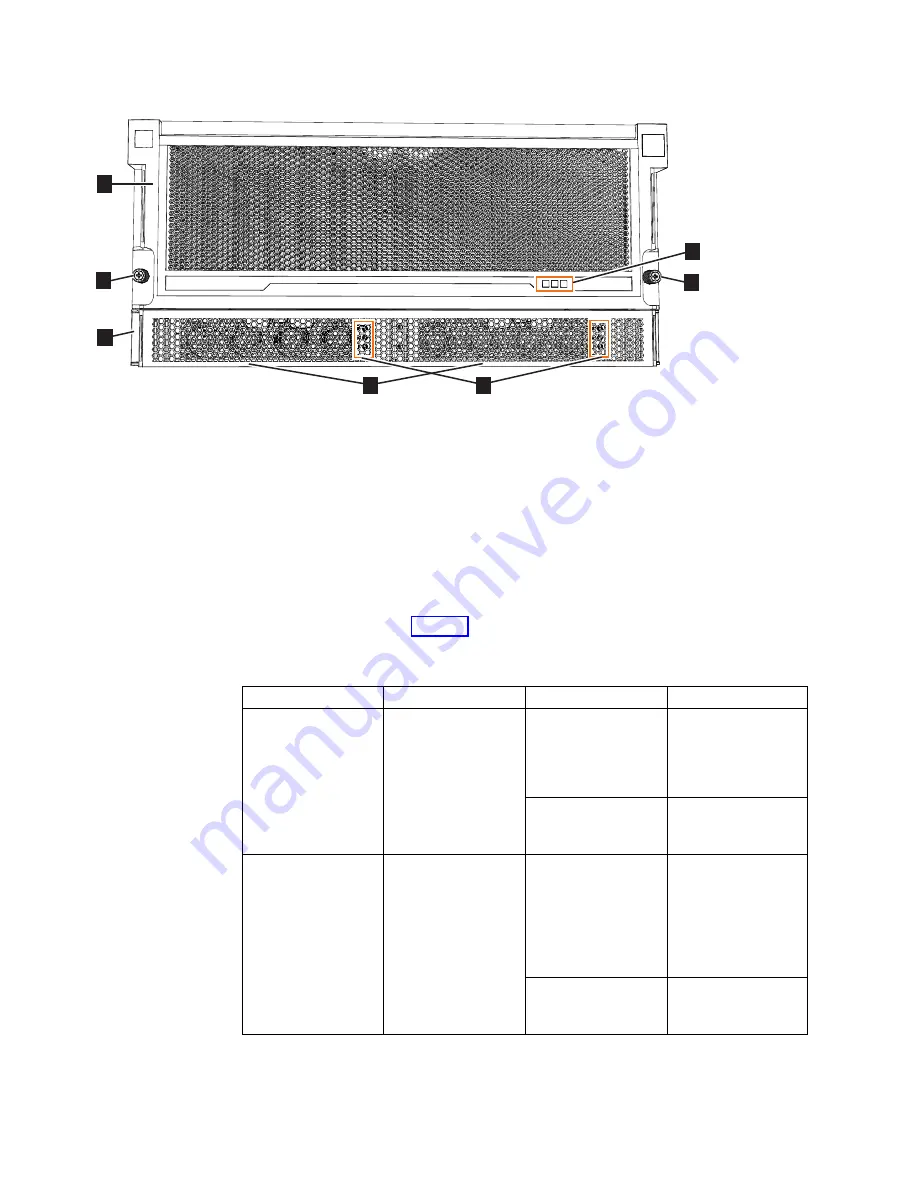

▌1▐

Display panel LEDs

▌2▐

Rack retention thumb screws

▌3▐

Power supply unit LEDs

▌4▐

Power supply units (PSUs)

▌5▐

PSU fascia (1U)

▌6▐

Front fascia (4U)

The display panel (

▌1▐

) contains three LEDs that describe the operational status of

the expansion enclosure. Table 15 describes the function and meaning of the LEDs

on the front display panel.

Table 15. Display panel LEDs

Function

Color

Status

Description

Power

Green

On

The expansion

enclosure power is

on; this LED is

controlled by the

expansion enclosure.

Off

The expansion

enclosure power is

off.

Identify

Blue

On

Identifies the

expansion enclosure;

this LED is controlled

by the system. Use

the management GUI

or service interface to

identify an enclosure.

Off

The expansion

enclosure is

operating normally.

svc00960

1

2

5

6

2

3

4

Figure 120. LEDs on the front of the expansion enclosure

132

Storwize V7000 Gen2 and Gen2+: Quick Installation Guide

Summary of Contents for StorVize V7000 Gen2

Page 8: ...viii Storwize V7000 Gen2 and Gen2 Quick Installation Guide ...

Page 24: ...xxiv Storwize V7000 Gen2 and Gen2 Quick Installation Guide ...

Page 36: ...12 Storwize V7000 Gen2 and Gen2 Quick Installation Guide ...

Page 166: ...142 Storwize V7000 Gen2 and Gen2 Quick Installation Guide ...

Page 174: ...150 Storwize V7000 Gen2 and Gen2 Quick Installation Guide ...

Page 176: ...152 Storwize V7000 Gen2 and Gen2 Quick Installation Guide ...

Page 184: ...160 Storwize V7000 Gen2 and Gen2 Quick Installation Guide ...

Page 187: ......

Page 188: ...IBM Printed in USA GC27 6500 08 ...