HySpeed HT2000

Instruction Manual

6-11

OPERATION

19

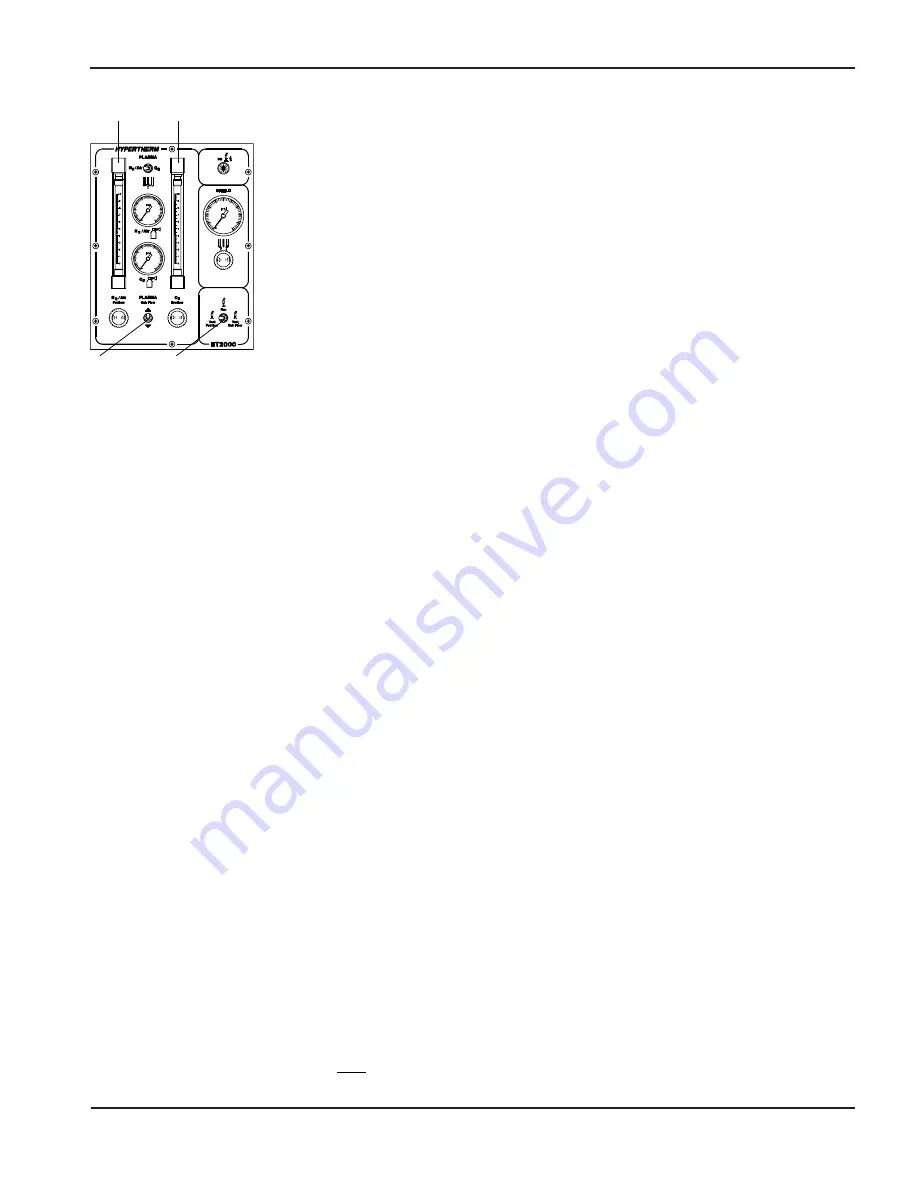

Adjust Cut Flow Gases and Prepare for Cutting

13. Set

S2

on the gas console to

Test Cut Flow.

14. Look at the oxygen (

FM2

) and/or nitrogen-air (

FM1

) flowmeters on the

gas console and set the

Cut Flow

plasma gas flow rate % by referring to

the

Cut Charts

and toggling the

Cut Flow

switch (

S3

) up or down.

Note: If you have changed consumable parts or if the power

supply has been off for more than one hour, purge gas

lines by leaving system in

Test Cut Flow

for one minute.

15. Set

S2

to

Run

after the test preflow and test operate flow rates have

been set.

The system is now ready for operation.

FM1

FM2

Common Cutting Faults

• Torch pilot arc will initiate, but will not transfer. Cause can be:

1. Work cable connection on cutting table not making good contact.

2. Malfunction in system. See

Section 8

.

• The workpiece is not totally penetrated, and there is excessive sparking on top of the workpiece. Causes

can be:

1. Current is set too low (check

Cut Chart

information).

2. Cut speed is too high (check

Cut Chart

information).

3. Torch parts are worn (see

Changing Consumable Parts

).

4. Metal being cut is too thick.

• Dross forms on the bottom of the cut. Causes can be:

1. Cutting speed is too slow or too fast (check

Cut Chart

information).

2. Arc current set too low (check

Cut Chart

information).

3. Torch parts are worn (see

Changing Consumable Parts

).

• Cut angle not square. Causes can be:

1. Wrong direction of machine travel.

High quality side is on the right with respect to the forward motion of the torch.

S2

S3

Summary of Contents for HT2000

Page 1: ...200 Volt Plasma Arc Cutting System Instruction Manual 802460 Revision 14 HySpeed HT2000 ...

Page 9: ......

Page 95: ...POST INSTALLATION 5 8 HySpeed HT2000 Instruction Manual 19 ...

Page 175: ...MAINTENANCE 8 30 HySpeed HT2000 Instruction Manual 22 ...

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 241: ......

Page 242: ......

Page 243: ......

Page 244: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 249: ......

Page 250: ......

Page 251: ......

Page 252: ......

Page 253: ......

Page 254: ......

Page 255: ......

Page 257: ......

Page 259: ......

Page 261: ......

Page 262: ...Coolant Flow Diagram ...

Page 263: ......

Page 265: ...APPENDIX A a 2 HySpeed HT2000 Instruction Manual 20 ...

Page 267: ...b 2 HySpeed HT2000 Instruction Manual 19 ...

Page 268: ...HySpeed HT2000 Instruction Manual b 3 19 ...

Page 269: ...b 4 HySpeed HT2000 Instruction Manual 19 ...

Page 270: ...HySpeed HT2000 Instruction Manual b 5 19 ...

Page 272: ...HySpeed HT2000 Instruction Manual b 7 19 ...

Page 273: ...b 8 HySpeed HT2000 Instruction Manual 19 ...

Page 274: ...HySpeed HT2000 Instruction Manual b 9 19 ...

Page 275: ...b 10 HySpeed HT2000 Instruction Manual 19 ...

Page 279: ...APPENDIX D d 2 HySpeed HT2000 Instruction Manual 19 ...

Page 285: ...APPENDIX E e 6 HySpeed HT2000 Instruction Manual 19 ...