HySpeed HT2000

Instruction Manual

6-9

OPERATION

24

Daily Start-Up

Prior to start-up, ensure that your cutting environment and that your clothing meet the safety requirements

outlined in the

Safety

section of this manual. If problems occur during start-up, refer to

Section 5

for the

system checkout requirements.

Note: For operation with argon-hydrogen manifold, see

Section 7 Operation: Argon-Hydrogen

Manifold

Check Torch

1. Remove the consumables from the torch and check for worn or damaged parts.

Always place the

consumables on a clean, dry, oil free surface after removing. Dirty consumables can cause the

torch to malfunction.

• Check the pit depth of the electrode using the electrode gauge assembly. An all copper electrode should

be replaced when the depth exceeds .040 inch (1 mm). A SilverPlus electrode should be replaced when

the pit depth exceeds approximately two times the recommended depth of an all copper electrode.

• Wipe the current ring in the torch with a clean paper towel or Q-tip (see Figure 6-7).

• Refer to the

Cut Charts

in this section to choose the correct consumables for your cutting needs.

2. Replace consumable parts. Refer to the

Changing Consumable Parts

section later in this manual for

detailed information on replacing consumables.

3. Ensure that the torch is squared to the material. Refer to

Section 4

: Installation for the torch alignment

procedure.

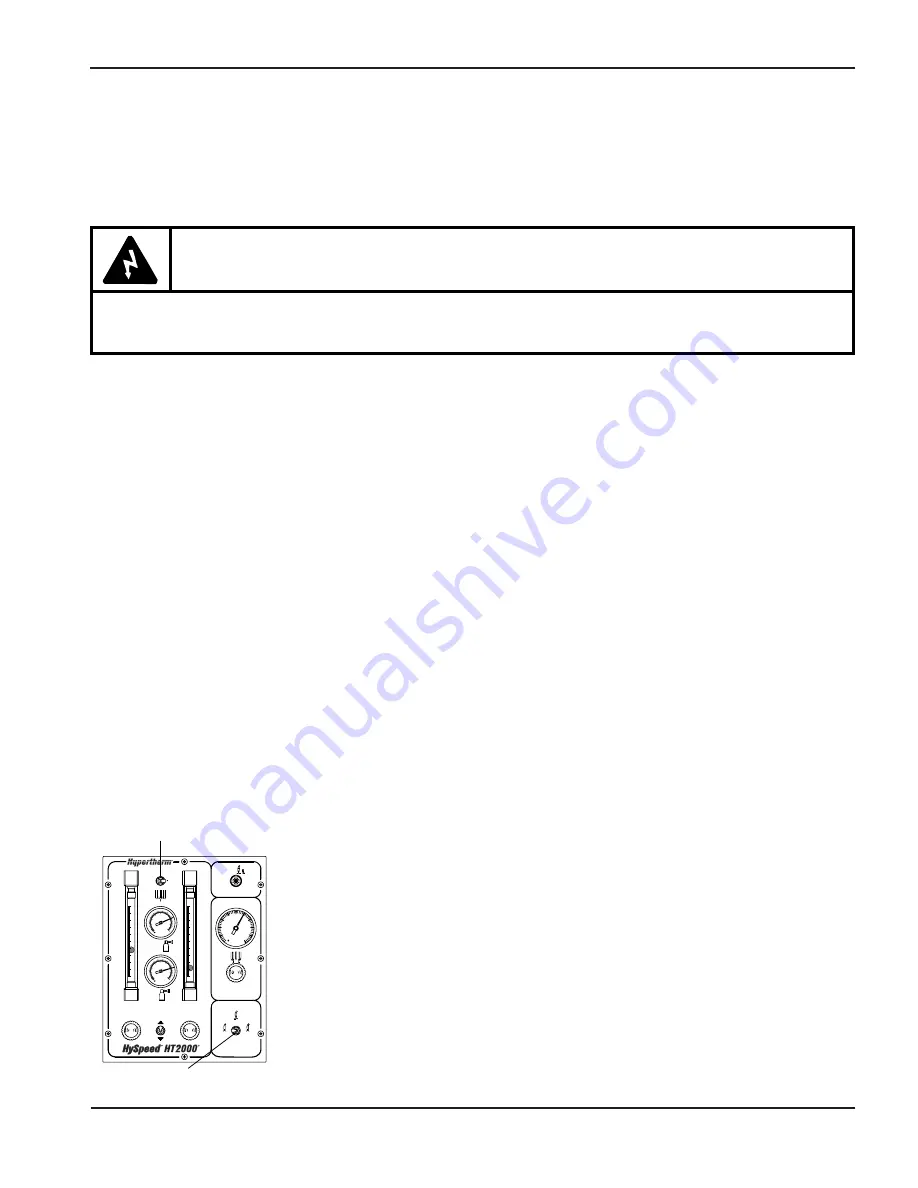

PLASMA

N

2

/Air

O

2

SHIELD

N

2

/Air

psi

psi

psi

DC

N

2

/Air

O

2

O

2

PLASMA

Cut Flow

PreFlow

PreFlow

Run

10

9

8

7

6

5

4

3

2

1

0

10

9

8

7

6

5

4

3

2

1

0

Test

Preflow

Test

Cutflow

S2

S1

WARNING

Before operating this system, you must read the Safety section thoroughly! Turn main disconnect

switch to the HT2000 power supply OFF before proceeding with the following steps

Turn Gases On

4. Set

S2

toggle switch on the gas console to

Run.

5. Set

S1

on the gas console to

N

2

/Air

(for nitrogen or air as plasma

gas), or

O

2

(for oxygen as plasma gas).

6. Turn the required supply gases

On.

Summary of Contents for HT2000

Page 1: ...200 Volt Plasma Arc Cutting System Instruction Manual 802460 Revision 14 HySpeed HT2000 ...

Page 9: ......

Page 95: ...POST INSTALLATION 5 8 HySpeed HT2000 Instruction Manual 19 ...

Page 175: ...MAINTENANCE 8 30 HySpeed HT2000 Instruction Manual 22 ...

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 241: ......

Page 242: ......

Page 243: ......

Page 244: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 249: ......

Page 250: ......

Page 251: ......

Page 252: ......

Page 253: ......

Page 254: ......

Page 255: ......

Page 257: ......

Page 259: ......

Page 261: ......

Page 262: ...Coolant Flow Diagram ...

Page 263: ......

Page 265: ...APPENDIX A a 2 HySpeed HT2000 Instruction Manual 20 ...

Page 267: ...b 2 HySpeed HT2000 Instruction Manual 19 ...

Page 268: ...HySpeed HT2000 Instruction Manual b 3 19 ...

Page 269: ...b 4 HySpeed HT2000 Instruction Manual 19 ...

Page 270: ...HySpeed HT2000 Instruction Manual b 5 19 ...

Page 272: ...HySpeed HT2000 Instruction Manual b 7 19 ...

Page 273: ...b 8 HySpeed HT2000 Instruction Manual 19 ...

Page 274: ...HySpeed HT2000 Instruction Manual b 9 19 ...

Page 275: ...b 10 HySpeed HT2000 Instruction Manual 19 ...

Page 279: ...APPENDIX D d 2 HySpeed HT2000 Instruction Manual 19 ...

Page 285: ...APPENDIX E e 6 HySpeed HT2000 Instruction Manual 19 ...