Page 35

supplied by the customer) need only be low-

voltage proof. If the system is modified on the

customer site, the digital inputs on the main

board and possibly on the extension board

must be parametrized accordingly (s. section

x).

The parameters in question are indicated

in context of the respective terminal wiring

depicted hereunder.

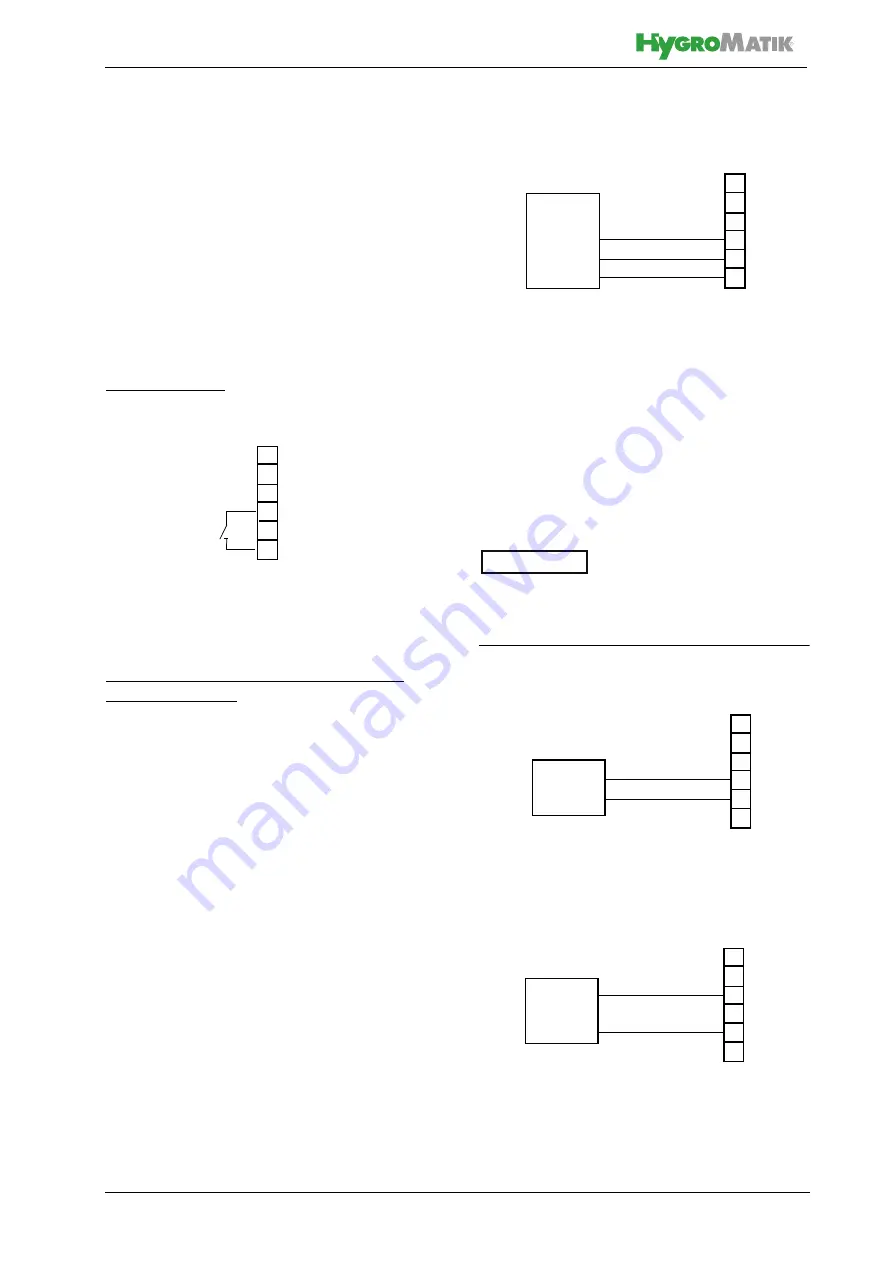

10.5.3.1 Terminal wiring for supply

air humidification (standard

delivery)

1-step operation

Operation with active humidity sensor or

external controller

When driving the high-pressure nozzle sys-

tem with an active humidity sensor or through

an external controller ( e.g. a PLC), physical

control signals in the range of 0...10 V, 0...20

mA or 0...140

Ω

can be used. For each of

the signal variants a particulat terminal is pro-

vided on the mainboard. In all cases, refer-

ence potential is terminal 4, „GND“.

Wiring variants (exemplary):

If an external control signal 0...10 V is used,

wiring is to be made to terminal 4 (GND) and

5 (signal) . Wiring for a resitive signal 0...140

Ω

is across terminals 4 and 7. A humidity

sensor with current output 0...20 mA is to be

wired across terminals 4 (GND) and 6.

Active humidity sensors require an external

supply voltage. Terminal 3 pr20 VDC

for that purpose.

20 VDC

Terminal strip on ST08

Terminal 3/5 wiring on the mainboard (terminal

strip on ST08) for 1-step operation

3

45

6

7

8

S1

S1: NO contacts

3

45

6

7

GND

0...10V

Terminal strip on ST08

8

External controller

Terminal 4/5 wiring on the mainboard (terminal

strip on ST08) for connection of a 0...10 V external

control signal

3

45

6

7

+20 VDC

Humidity sensor

GND

0...10V

8

Terminal 3/4/5 wiring on the mainboard (terminal

strip on ST08) for connection of a humidity sensor

0...10 V

Terminal strip on ST08

3OHDVHQRWH

3

45

6

7

GND

8

Terminal 4/6 wiring on the mainboard (terminal

strip on ST08) for connection of a 0...20 mA control

signal

0...20mA

Terminal strip on ST08

External controller