7

Page

Installation

Manual

INSTALLATION

GENERAL

1.

Follow all local codes, or in the absence of local codes, follow the most recent

edition

of the Na

tional

Fuel Gas Code: ANSI Z223.1/NFPA 54 in the USA or CAN/CSA B149.1 Natural Gas, Propane Installa

tion

Code in Canada.

2.

All gas micro-boilers require careful and correct installa

tion

to ensure safe and e

fficie

nt opera

tion.

This manual must be followed exactly. Read the “Safety Guidelines”

section

.

3.

The manifold gas pressure is preset at the factory. It is computer controlled and should not need

adjustment.

4.

Maintain proper space for servicing. Install the micro-boiler so that it can be connected or removed

easily. Refer to the "Clearances"

section

on p. 9 for proper clearances.

5.

The micro-boiler must be installed in a loca

tion

where the proper amount of combus

tible

air will be

available to it at all

times

without obs

tructions

.

6.

The electrical c

onnection

requires a means of disc

onnection,

to terminate power to the micro-boiler

for servicing and safety purposes.

7.

Do not install the micro-boiler where the exhaust vent is poin

ting

into any opening in a building or

where the noise may disturb your neighbors. Make sure the vent termina

tion

meets the required

distance by local code from any doorway or opening to prevent exhaust from entering a building (refer

to p. 17 to 19).

8.

P

articles

from

flou

r, aerosols, clothes dryers and other airborne contaminants may clog the air vent,

build up and reduce the

functions

of the rota

ting

fan, cause improper burning of the gas, or cause

damage to the micro-boiler. Regularly ensure that the area around the micro-boiler is dust- or debris-

free. Regular maintenance is recommended for these types of environments. Sealed combus

tion

is

recommended too.

9.

The Hydro Smart 120 micro-boiler is to be installed indoors only. The model is equipped with a

thermistor and hi-limit switch for the exhaust gas, det

ecting

excess temperatures within the

flue

and

enabling the micro-boiler to safely stop opera

tion

if needed. These components are always monitoring

exhaust gas c

onditions

in order to prevent heat damage to ABS, PVC, CPVC, or Polypropylene (Plas

tic)

ven

ting

if ABS, PVC, CPVC, or Polypropylene is used. If the exhaust gas temperature exceeds 140 °F

(60 °C) these components will enable the micro-boiler to safely stop opera

tion.

•

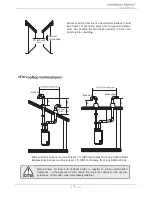

The micro-boiler requires 3 inch, or 4 inch diameter intake air supply pipe. The intake pipe must

be sealed

airtig

ht.

•

Air supply pipe can be made of aluminum

fl

exible tube, ABS, PVC, CPVC, Polypropylene,

corrugated stainless steel, or Category lll / IV stainless steel. Regarding exhaust pipe, please refer

to p.11 for detailed informa

tion

.

•

Sidewall ven

ting

is recommended for this boiler. V

erti

cal ven

ting

(roof termina

tion)

is

acceptable.

•

The manufacturer recommends running the exhaust vent and the intake pipe as parallel as possible.

Summary of Contents for HS120CON-LP

Page 27: ......