Mist-n-Go User Manual

www.HydromistUSA.com

19

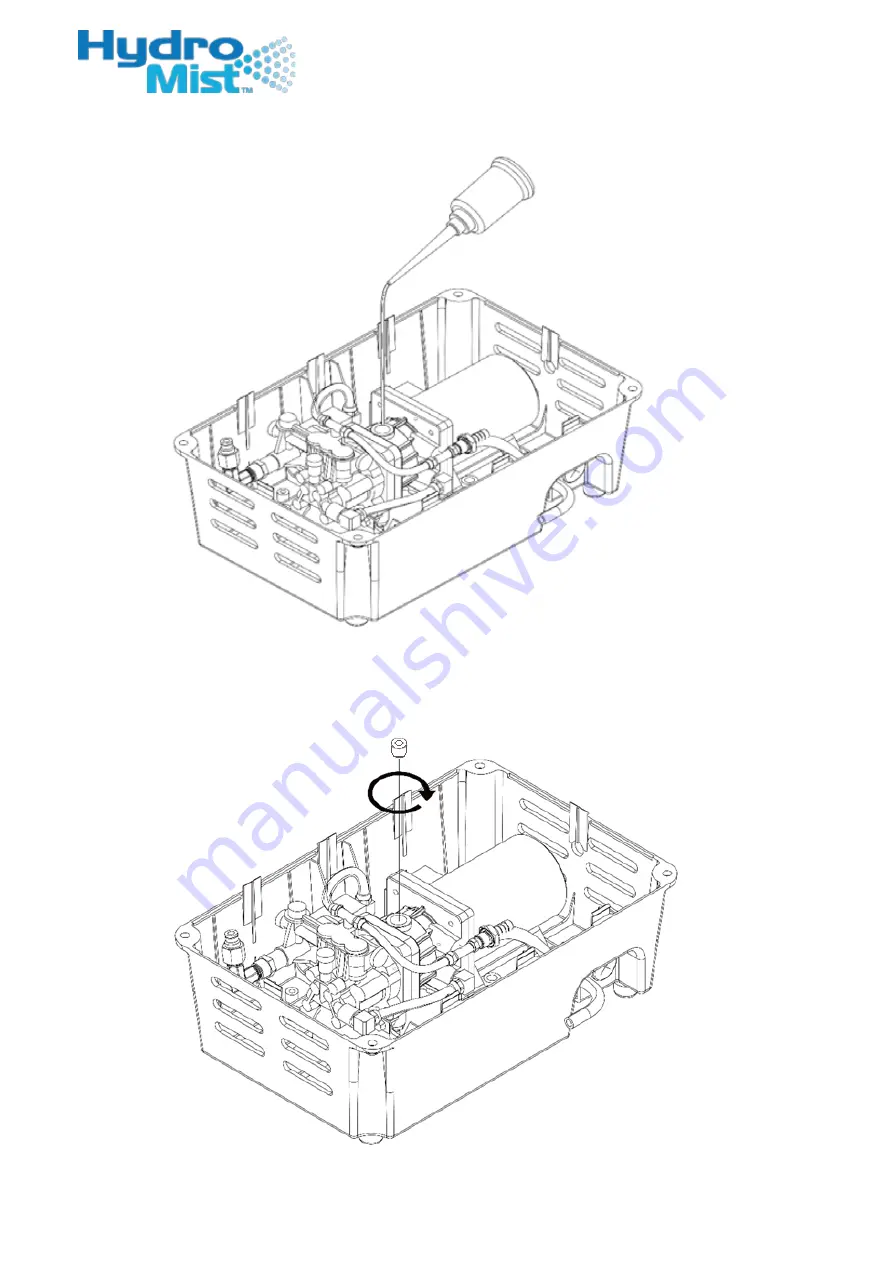

7.2.10

A

dd 1.5 to 2 oz. (40-60 ml) oil through refill hole.

7.2.11

Tighten the oil fill plug.

Wipe up any spilled oil.

Visually check the pump

and motor to ensure all bolts, screws and connectors are tight and in good

condition.